A clamping mechanism and traction machine using the clamping mechanism

A technology of clamping mechanism and tractor, applied in the field of tractor, can solve the problems of easily damaged profile surface and time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a1

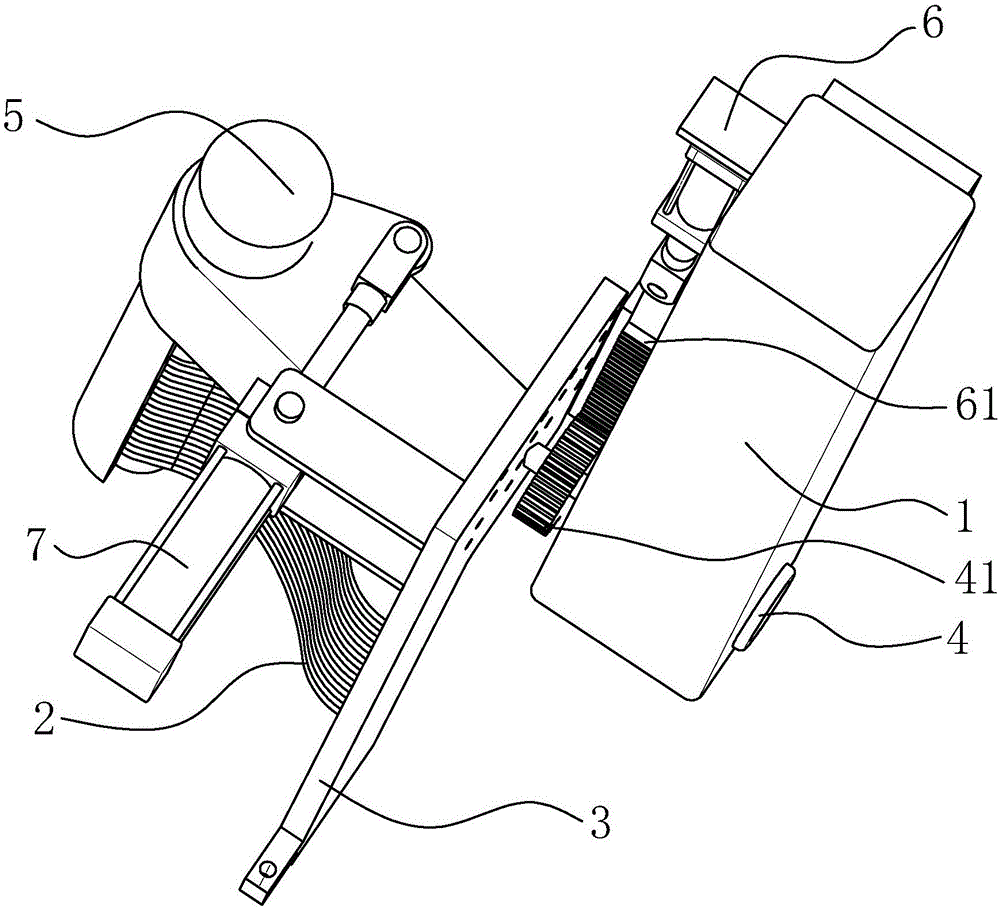

[0024] Embodiment a1: with reference to figure 1 , is an embodiment of the clamping mechanism of the present invention.

Embodiment a2

[0025] Embodiment a2: with reference to figure 2 , is another embodiment of the clamping mechanism of the present invention.

[0026] Embodiment a1 and embodiment a2 have the same connection and driving relationship of their components, and their working principles are also the same, as follows:

[0027] The clamping mechanism includes a base frame assembly 1 and a clamping assembly. The base frame assembly 1 is provided with a longitudinally extending longitudinal axis assembly 4 and a transversely extending horizontal axis assembly 5; the clamping assembly includes an upper The claw assembly and the supporting plate 3; the supporting plate 3 that can rotate around the axis of the longitudinal axis assembly 4 is connected with the vertical axis assembly 4, and the upper claw assembly that can rotate around the axis of the horizontal axis assembly 5 is connected with the horizontal axis assembly 5; The longitudinal axis assembly 4 is connected with the longitudinal axis driv...

Embodiment a3

[0031] Embodiment a3: with reference to image 3 with Figure 4 , a traction machine, including a frame 8 and a clamping unit arranged on the frame 8, the clamping unit includes a guide rail group, a connecting frame 11, and a clamping mechanism; the frame 8 is provided with a guide rail group extending forward and backward The connecting frame 11 that moves back and forth on the guide rail group is provided with a clamping mechanism; the described guide rail group is provided with an upper guide rail 91 and a lower guide rail 92 connected with the connecting frame 11 from top to bottom, and the connecting frame is provided with a guide rail The sliding roller assembly on the set enables the connecting frame 11 to move smoothly and quickly on the guide rail set.

[0032] Furthermore, the sections of different profiles are large and small, in order to adapt to different profiles; at the same time, after a longer profile is pulled out for a longer distance, there will be a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com