Construction Technology of Turning and Excavating by Hanging and Reloading Machine

A construction technique and transfer machine technology, which is applied in ground mining, earthwork drilling, underground transportation, etc., to reduce the labor intensity of employees, prevent off-track accidents of transfer machines, and improve the safety production factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

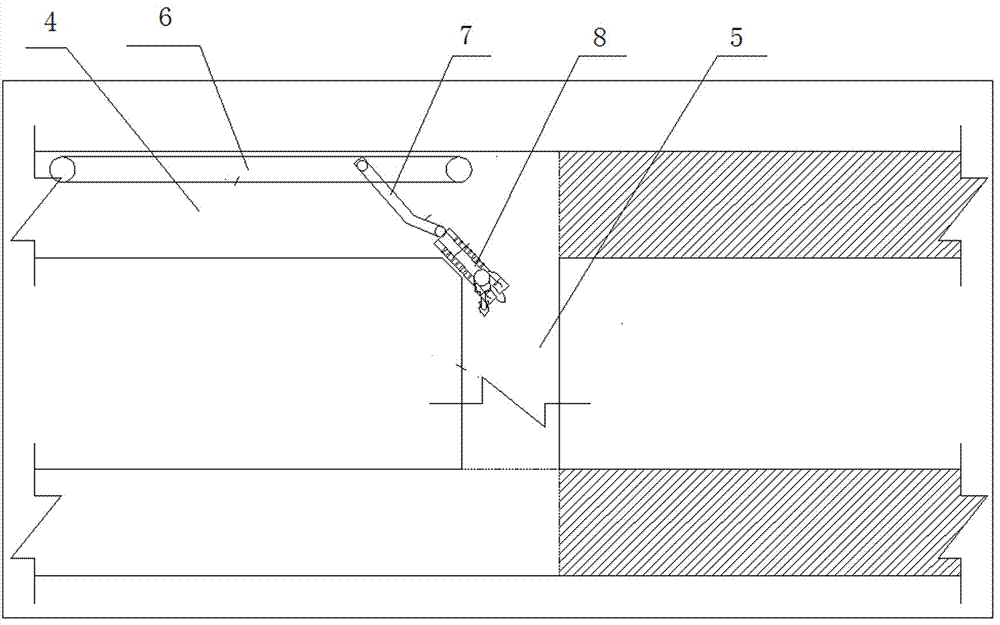

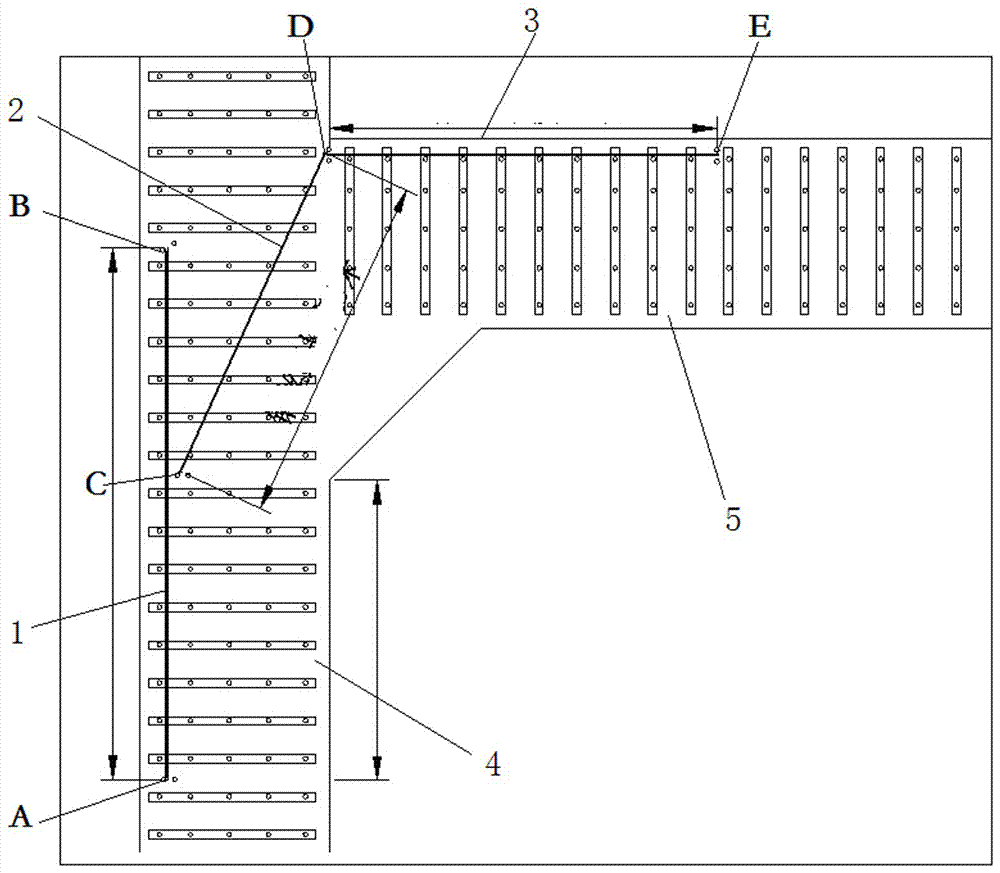

[0013] A construction technology for turning and excavating with a hanging loader. The roadheader 8 excavates to the inflection point in the roadway 4. Before the roadway is ready to turn to Hengchuan 5, as figure 2 As shown, select 2 points (A, B) along the direction of the roadway at the roof of the roadway 4, place two lifting anchors at each point, connect the two anchors with anchor chains, and fix the steel wire rope 1 on the two strands. Between the anchor chains; then select a point C on the roof of the roadway, and a point D in the roof of Hengchuan, and place two lifting anchor rods at each point, connect the two anchor rods with anchor chains, and fix the wire rope 22 on Between the two strands of anchor chains; select a point E along the direction of the roadway at the roof of Hengchuan, place two lifting anchors at each point, connect the two anchors with anchor chains, and fix the wire rope 33 on the two strands of anchors between chains;

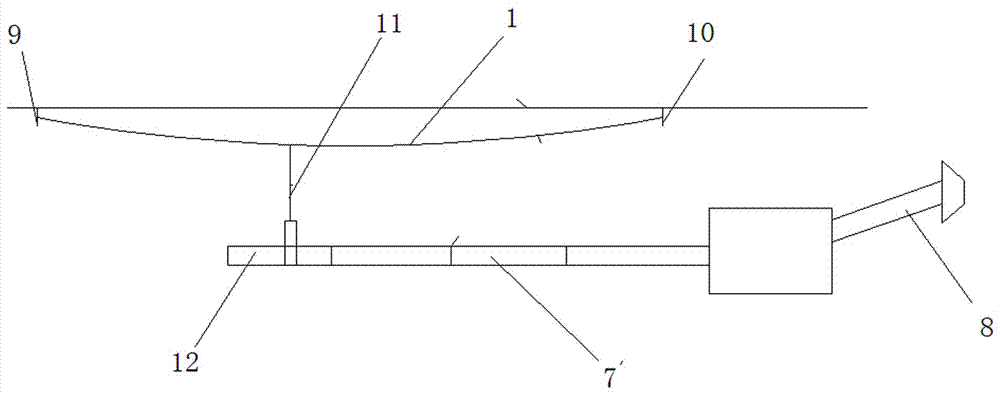

[0014] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com