A method for measuring the productivity of shale gas wells

A shale gas well and measurement method technology, applied in the field of geophysical exploration, can solve the problem of inability to directly and accurately obtain the stable production period of gas wells, production decline and final cumulative gas production, unusable gas well productivity, and large errors in shale gas well productivity results, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make the technical content disclosed in the present invention more detailed and complete, the purpose, technical solutions and technical effects of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that although the description is made with reference to the accompanying drawings, those skilled in the art should understand that the accompanying drawings and the embodiments are not intended to limit the scope of the present invention.

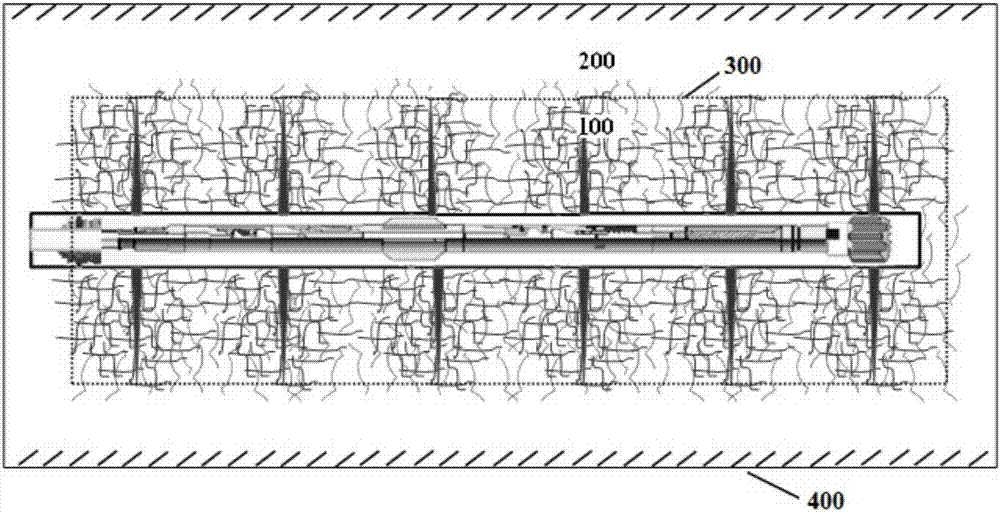

[0076] Such as figure 1 As shown, the present invention is a schematic diagram of the single well control area of a multistage fracturing horizontal well in a shale gas reservoir. The control area of a single well in a shale gas reservoir can be divided into two parts: the fractured stimulation area 100 and the unfractured stimulation area 200 according to the well pattern spacing. The fracturing stimulated area 100 is an area wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com