Hole digging machine capable of realizing anchorage through manual control and running safely

A technology of safe operation and hole digging machine, applied in the direction of planting method, rotary drilling machine, drilling equipment and method, etc., can solve the problem of increasing equipment cost and use cost, difficult to adapt to construction conditions and requirements, and will not be well applicable Digging operations and other problems, to achieve the effect of increasing flexibility, increasing diameter, reducing thread lead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

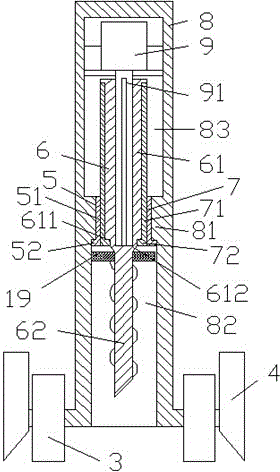

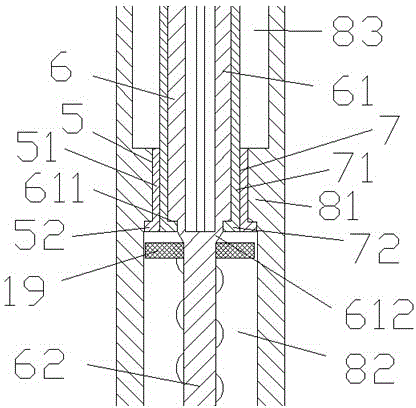

[0012] Combine below Figure 1-3 The present invention will be described in detail.

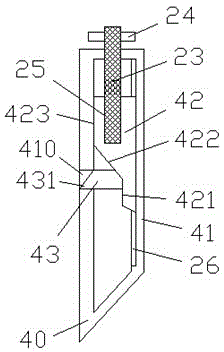

[0013] The hole digging machine with manual control anchoring and safe operation according to the embodiment includes an external housing 8, a driving motor 9 and a drilling rod part 6 driven by the driving motor 9, wherein the driving motor 9 is arranged on the outside The drive motor 9 is in the casing 8 and the drive motor 9 is axially slidably power-coupled with the spline hole in the drive sleeve part 61 of the digging drill rod part 6 through the spline rod 91 fixedly connected. The driving sleeve part 61 of the hole drilling rod part 6 is fixedly connected with the drilling rod part 62 of the drilling rod part 6 through the tapered connection part 612, and the outer peripheral surface of the driving sleeve part 61 is provided with an axial extension key for Cooperate with the axially extending keyway on the inner peripheral wall of the cylinder 71 of the externally threaded sleeve par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com