Vacuum-assisted grouting system with multiple grouting ports for abandoned pipelines

A waste pipeline, vacuum-assisted technology, applied in construction, infrastructure engineering and other directions, can solve the problems of the strength not meeting the filling requirements, the water separation of the cement mortar, and the insufficient grouting power, so as to improve the grouting speed and the injection rate. The effect of increasing the grouting power, eliminating the stratified water and increasing the grouting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

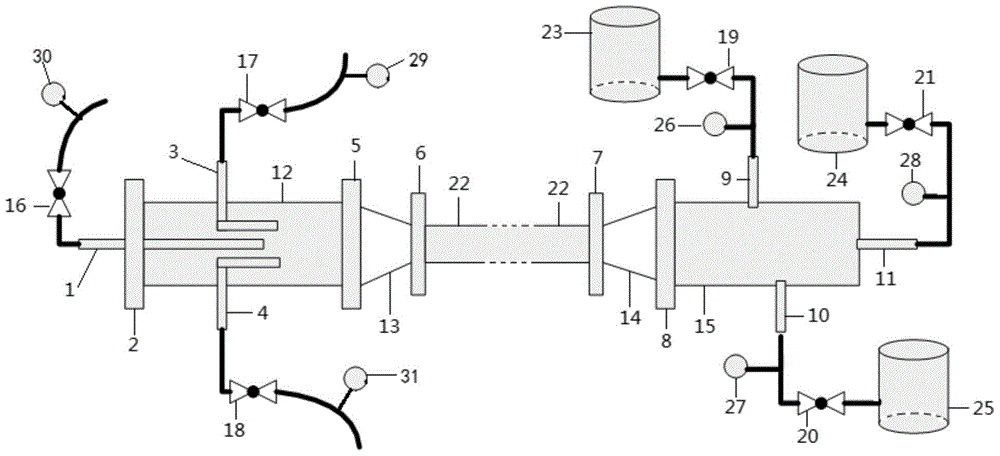

[0037] The embodiment of the present application provides a vacuum-assisted grouting system with multiple grouting ports for waste pipelines, such as figure 1 shown, including:

[0038] The grouting cylinder 12, the front end of the grouting cylinder 12 is connected with one end of the waste pipeline 22;

[0039] M grouting ports (for example: grouting port 1, grouting port 3, grouting port 4), arranged on the rear end and / or sidewall of the grouting cylinder 12, M is an integer greater than or equal to 2;

[0040] Grouting pump (for example: grouting pump 29, grouting pump 30, grouting pump 31), is connected with M grouting port, is used for slurry (for example: is used for the cement mortar that is used for blocking waste pipeline) Inject into the grouting cylinder 12 through M grouting ports, and inject into the waste pipeline 22 through the grouting cylinder 12;

[0041] Vacuum cylinder 15, the front end of grouting cylinder 12 is connected with the other end of waste pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com