Sewing needle

A technology of sewing needles and needle bars, which is applied to sewing equipment, sewing machine components, machine needles, etc., and can solve the problems of impractical threading and threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

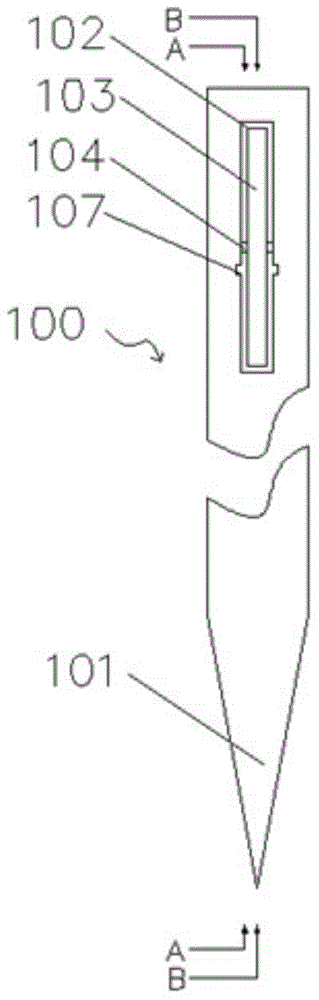

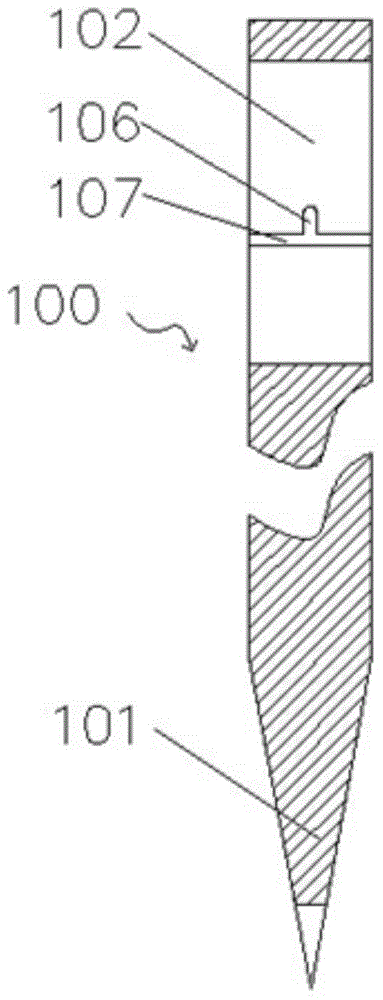

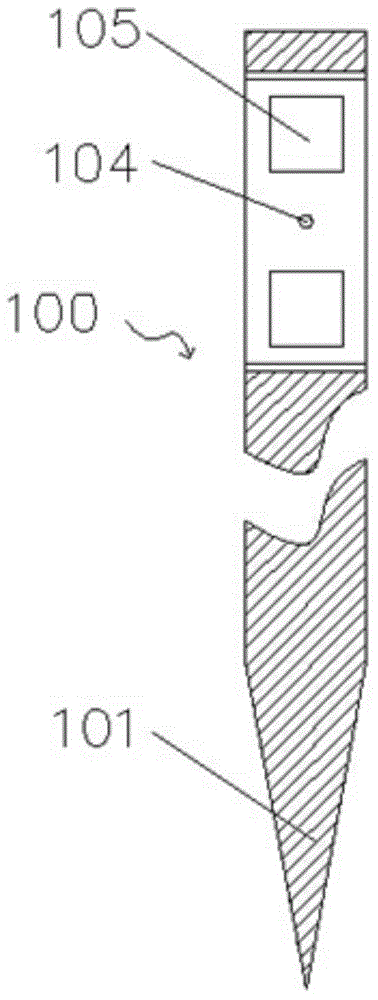

[0018] see Figure 1 to Figure 6 , as shown in the legend therein, a sewing needle includes a needle bar 100, one end of the needle bar 100 is a needle point 101, and the other end of the needle bar 100 is provided with a through first threading hole 102, and the above sewing needle also includes a threading Sheet 103, the threading sheet 103 is hingedly connected on the inner wall of the first threading hole 102 through the hinge shaft 104, the hinge shaft 104 is perpendicular to the axis of the first threading hole 102, the threading sheet 103 is provided with the second threading hole 105 through.

[0019] The inner wall of the first threading hole 102 is provided with a relative connection groove 106, the connection groove 106 extends along the direction of the axis of the needle bar 100, one end of the connection groove 106 is a semicircular groove end, and the other end of the connection groove 106 connects through the There is an inlet and outlet slot 107, which extends...

Embodiment 2

[0024] The rest is the same as the first embodiment above, the difference is that the inner wall of the first threading hole is provided with a relative connection groove, the connection groove extends along a direction perpendicular to the axis of the needle bar, and one end of the connection groove is a semicircular groove end, the other end of the connecting groove runs through the outer wall of the needle bar, and the hinge shaft is connected at the end of the semicircular groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com