Concentric circle gas separation device

A technology of gas separation and concentric circles, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low adsorption efficiency of gas separator, uneven air distribution, buckling and deformation of shell structure, etc., and achieve sealing performance Excellent, guaranteed adsorption effect, not easy to buckle and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

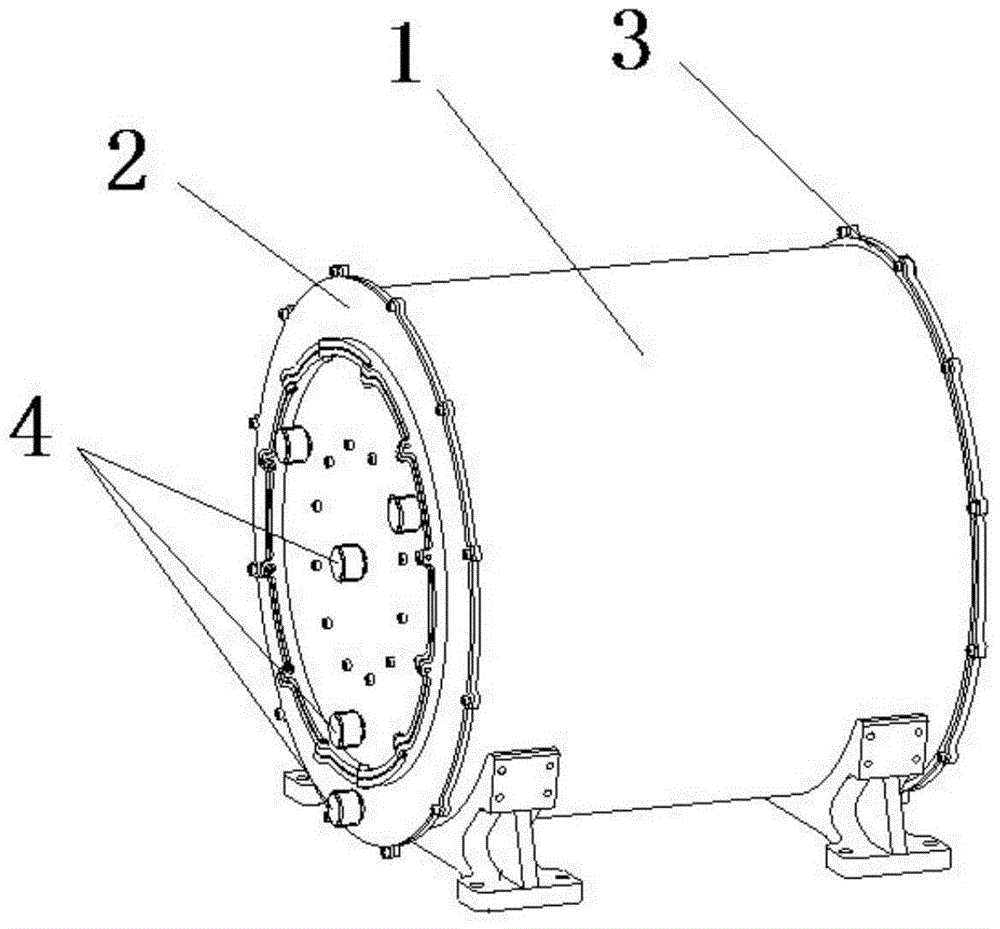

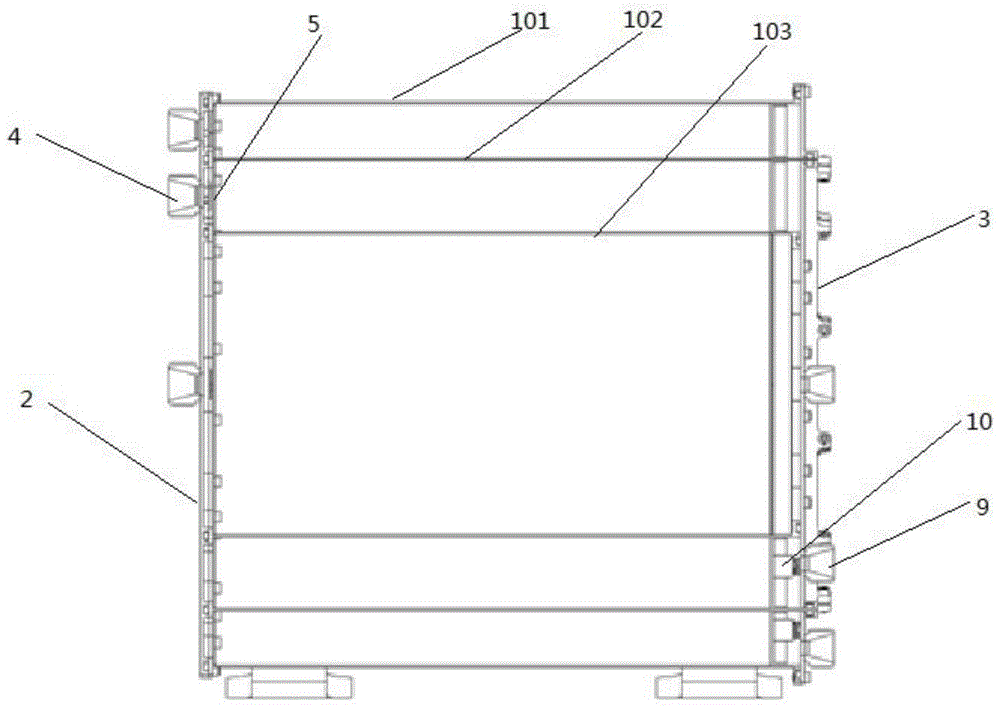

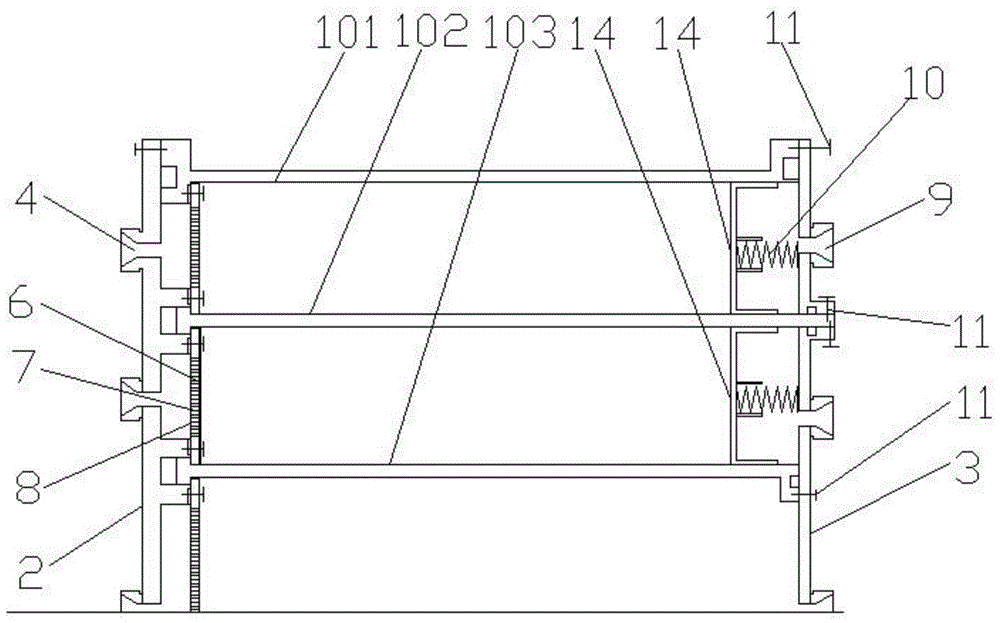

[0029] see Figure 1 to Figure 6 , a concentric gas separation device according to a preferred embodiment of the present invention, comprising a cylinder body 1 and an inlet-side end cover 2 and an outlet-side end cover 3 respectively arranged at both ends of the cylinder body 1, and the inlet-side end cover 2 A number of air inlets 4 are arranged on the top, and a number of air outlets 9 are arranged on the outlet side end cover 3. The air flow enters through the air inlet 4, and flows out from the air outlet 9 after the gas is separated. The cylinder body 1 of the present invention comprises an inner layer cylinder body 103, a middle layer cylinder body 102 and an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com