Water culture bed set and production method thereof

A manufacturing method and water bed technology, applied in botany equipment and methods, agricultural gas emission reduction, surface pretreatment, etc., can solve the problems of uneven crop growth space, troublesome real help, limited and other problems, and improve the overall planting efficiency , to avoid leakage or dirt, to simplify the effect of cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A hydroponic bed set and its manufacturing method according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same reference symbols.

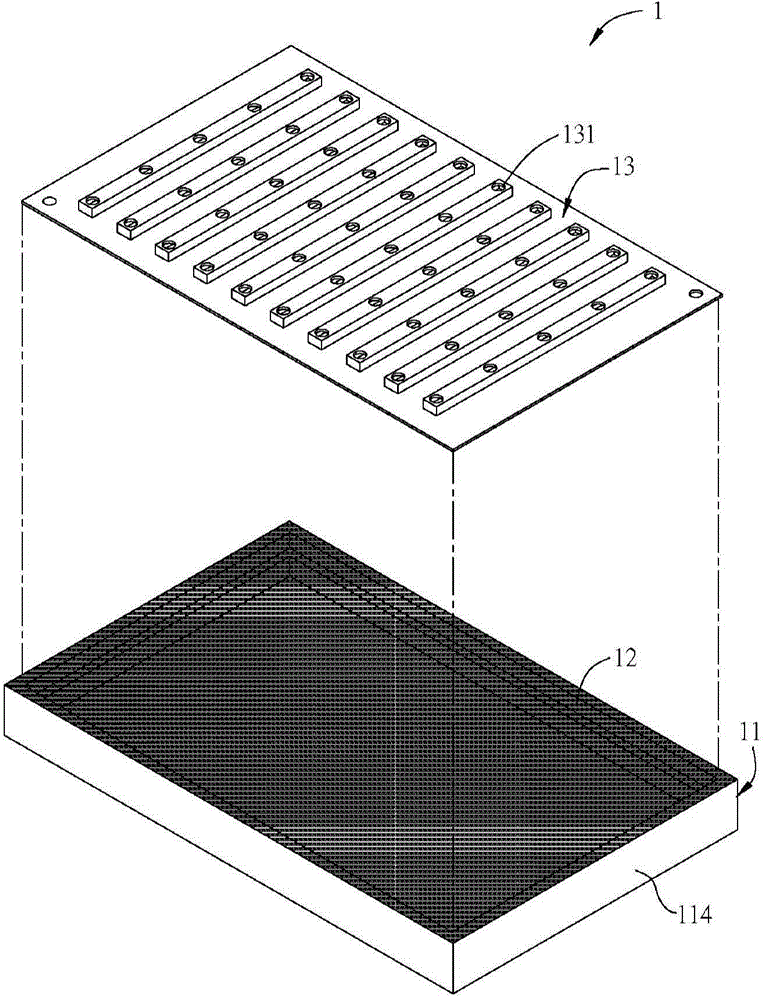

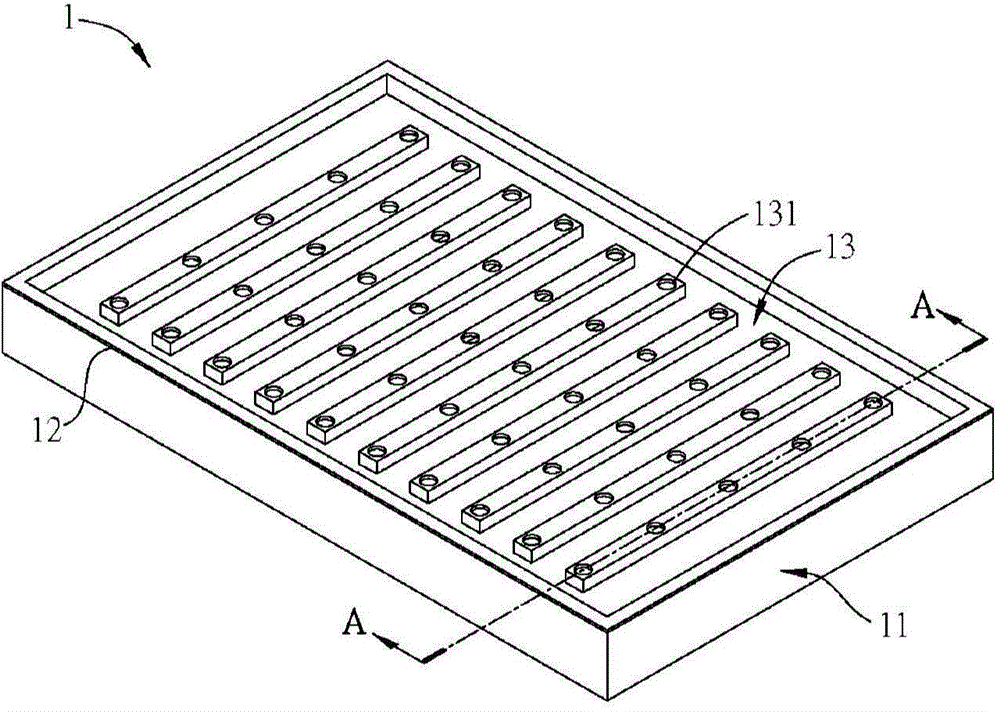

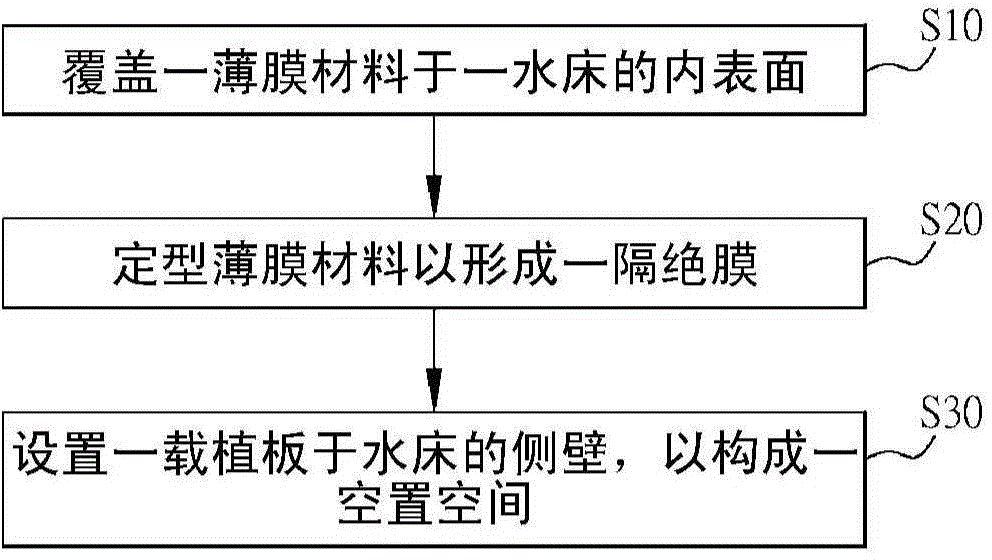

[0051] Figure 1A It is a schematic diagram of a hydroponic bed group according to an embodiment of the present invention, Figure 1B for Figure 1A A combined schematic diagram of the hydroponic bed set shown. Such as Figure 1A and Figure 1BAs shown, the hydroponic bed set 1 of this embodiment includes a water bed 11 , an insulating film 12 and a planting board 13 . also, figure 2 It is a schematic flowchart of a method for manufacturing a hydroponic bed group according to an embodiment of the present invention. Please also refer to figure 2 As shown, the manufacturing method of the hydroponic bed group 1 of this embodiment includes the following steps: covering a film material on the inner surface of a water bed (st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com