Multifunctional high-temperature stretching clamp

A multi-functional, clamp technology, applied in the field of tensile clamps, can solve the problems of inconvenient operation, inconvenient sampling, inconvenient measurement, etc., and achieve the effect of simple structure, fast clamping and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

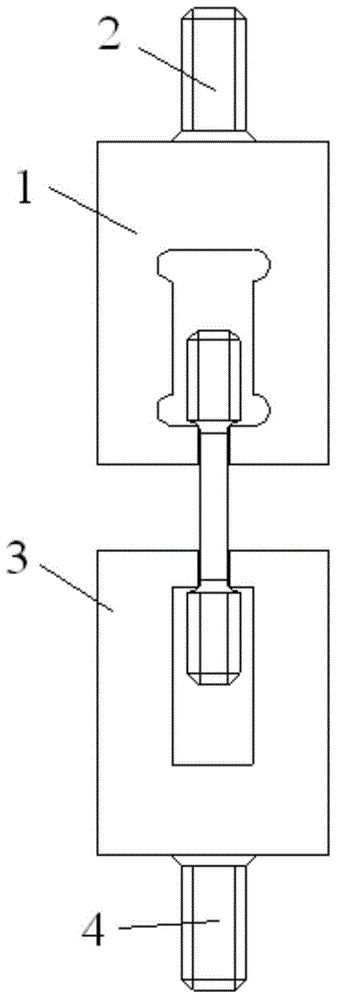

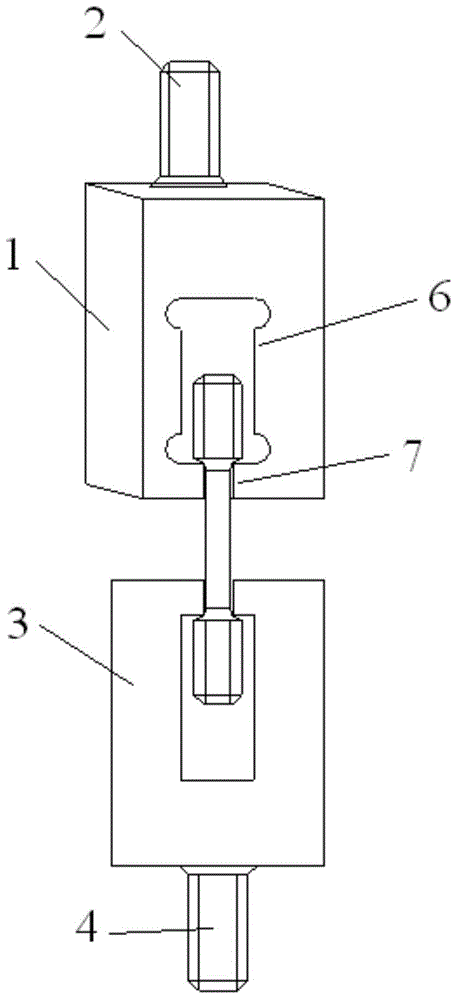

[0030] like Figure 2~3 As shown, a multifunctional high-temperature tensile clamp of the present invention includes an upper clamp and a lower clamp. The upper clamp includes an upper clamp block 1 and an upper tie rod 2 welded above it. The upper pull rod 2 is a threaded rod, and the upper clamp block 1 It is threadedly connected to the stretching device through the pull-up rod 2. The lower part of the upper clamping block 1 is provided with a slot, which includes a bottom guide groove 7 and a clamping groove 6 connected thereto. The width of the top of the guide groove 7 is smaller than the width of the bottom of the clamping groove 6, which blocks the upper end of the rod body to be tested. In the holding groove 6, it is prevented from falling out. There is a gap of 1-5 mm between the guide groove 7 and the rod body to be tested, which is convenient for taking out and putting in the rod body to be tested, and prevents the rod body from being scratched. The clamping groov...

Embodiment 2

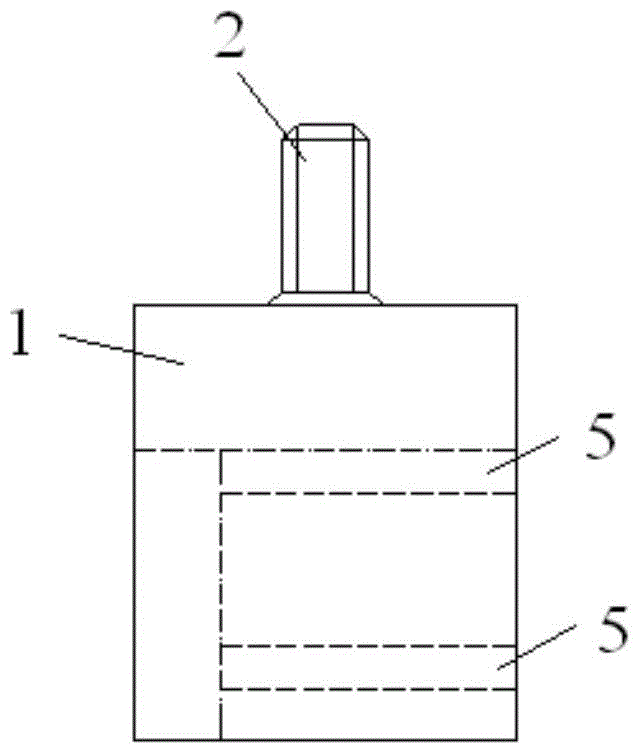

[0037] The clamping groove 6 of the upper clamping block 1 is in the shape of a cuboid, the depth is greater than the thickness of the upper end of the sample to be tested and less than the thickness of the upper clamping block 1, and the bottom and top are provided with an extension groove 5 extending outward, and the extension groove 5 is rectangular Through holes; the clamping groove 6 of the lower clamping block 3 is in the shape of a cuboid, and the depth is the same as the thickness of the upper clamping block 1, forming a through hole; other than that, it is the same as that of Embodiment 1.

Embodiment 3

[0039] The clamping groove 6 of the upper clamping block 1 is cuboid, and the depth is the same as the thickness of the upper clamping block 1, forming a through hole; the clamping groove 6 of the lower clamping block 3 is cuboid, and the depth is greater than the thickness of the upper end of the sample to be tested. The thickness of the upper clamping block 1, and the bottom and the top are provided with an extension groove 5 extending outward, and the cross section of the extension groove 5 is a semicircular arc; other than that, it is the same as the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com