A method and test device for determining relative density sample preparation standard for indoor scale test of coarse aggregate

A relative density and indoor test technology, applied in the field of indoor scale test sample preparation standards, can solve the problems of overestimation of the mechanical property parameters of the original gradation coarse-grained material, unsafety, and poor compaction performance of the scale gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

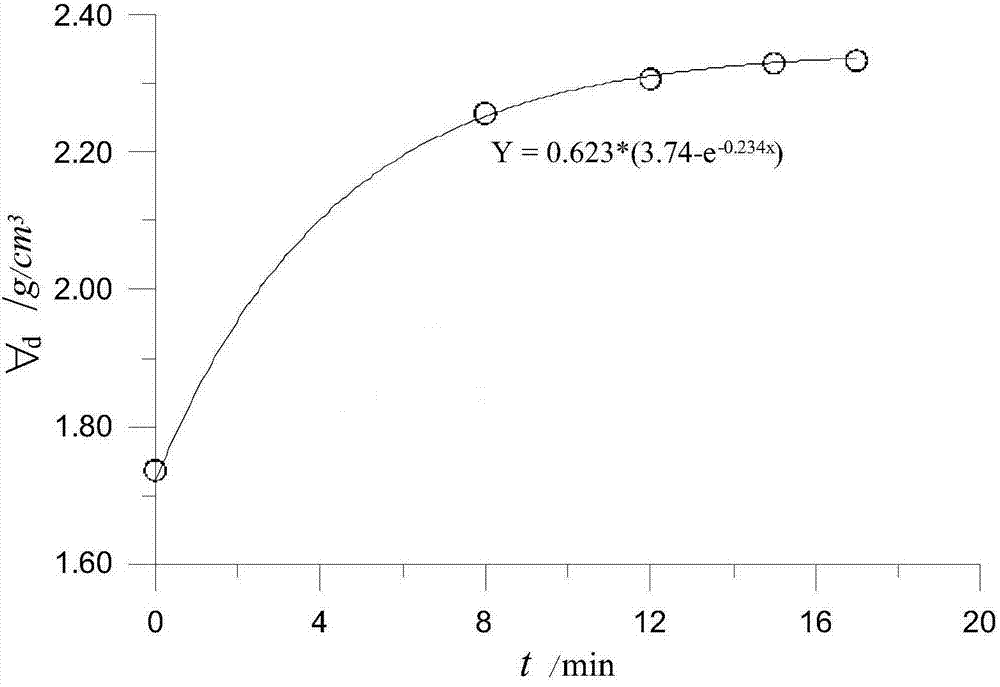

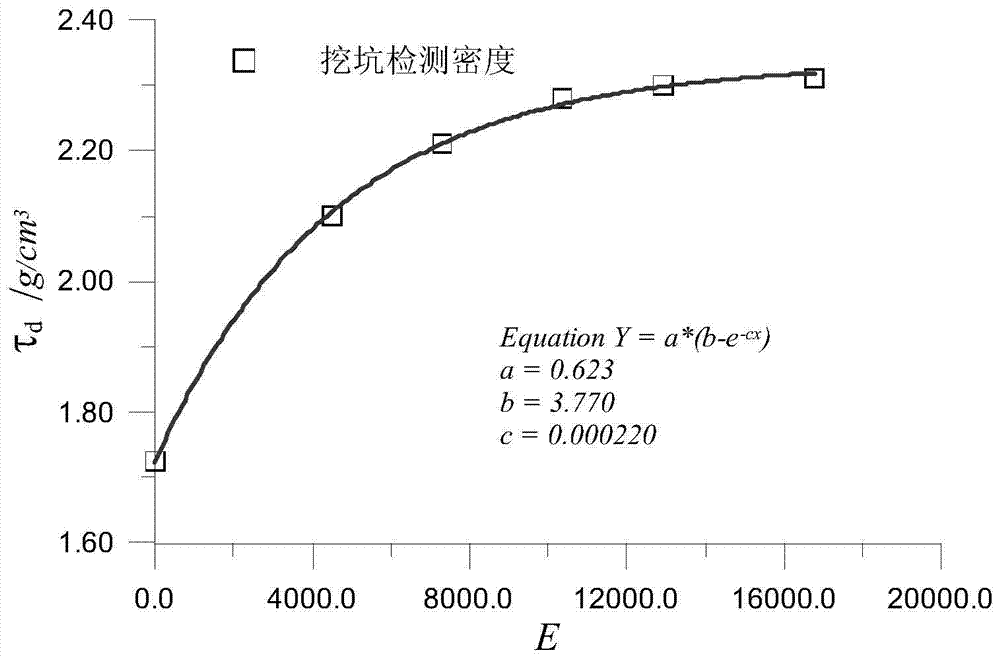

[0060] This implementation case determines the sample preparation standard for the indoor scale test of the original graded rockfill material of a project. The dam of the project is located in a strong earthquake area, and the design index of the relative density of the filled rockfill material is 0.80. Attached Table 1 is the test cushion materials and rockfill materials, all taken from the dam construction site. The maximum particle size of the test rockfill material is 600mm, and the diameter-to-diameter ratio with the indoor test instrument is equal to 0.5, and the indoor test needs to be scaled down; the mixed method is used to scale down, firstly, the similar gradation method is used to scale down, and the reduction factor of the particle size is 6 , and then treat the super-sized particles by the equivalent substitution method. The obtained scale gradation, that is, the gradation of the indoor test, is shown in Attached Table 1.

[0061] Attached Table 1 Test Coarse Ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com