Cushion pad of shock absorber for car

A buffer pad and shock absorber technology, which is applied in the field of auto parts, can solve the problems of wear, bumps, and safety hazards in automobiles, and achieves the effect of prolonging the service life and reducing the wear problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

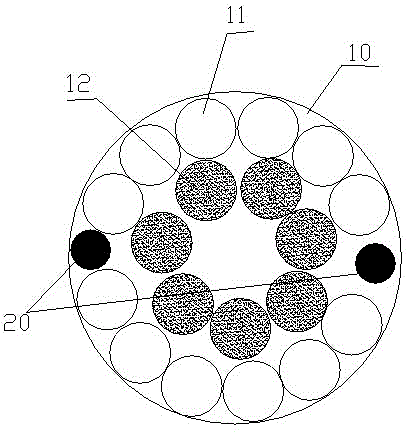

[0012] The buffer pad structure of the automobile shock absorber of preferred embodiment of the present invention is as figure 1 As shown, it includes a rubber cushion body 10 and a metal connecting piece 20 connected to the shock absorber; wherein, the rubber cushion body 10 and the metal connecting piece 20 are fixedly connected by an integral vulcanization method, and the surface of the rubber cushion body 10 is provided with a plurality of The buffer groove 11 and the buffer protrusion 12, and the buffer groove 11 and the buffer protrusion 12 are evenly distributed on the surface of the rubber cushion body 10; the bottom surface and the side of the buffer groove 11 are set as connected arc surfaces, and the buffer protrusion The outer surface of 12 is connected with the arc surface of the buffer groove 11 in a smooth transition.

[0013] Preferably, in the above embodiments, the rubber cushion body 10 is a hollow structure, and a sound-absorbing layer made of sound-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com