Sleeve Buckling Restrained Brace

A buckling-constrained, sleeve-type technology, applied to building components, shockproof, etc., can solve the problems of long calculation length, large amount of material consumption, and low material utilization rate, so as to save materials, meet architectural requirements, and achieve the best economic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

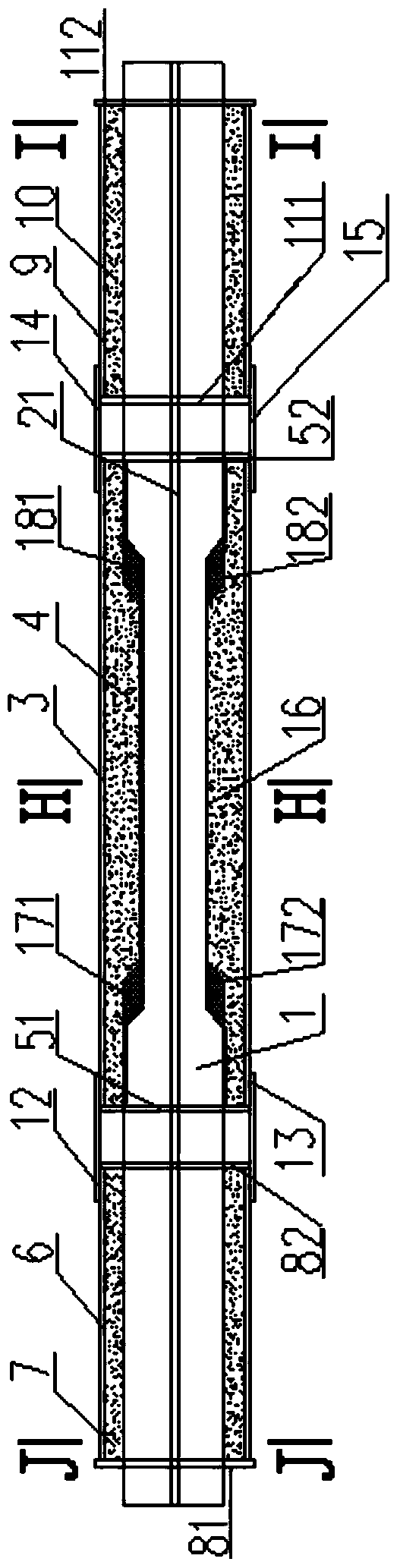

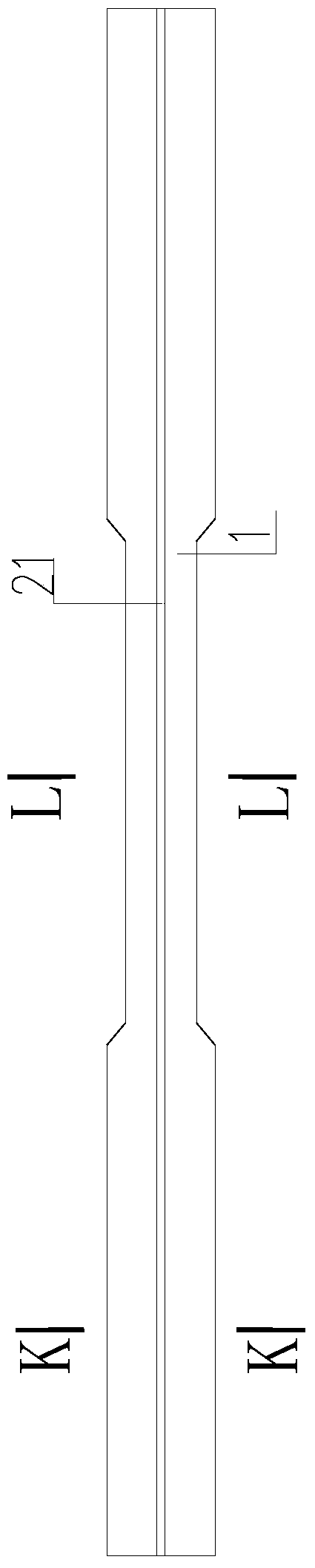

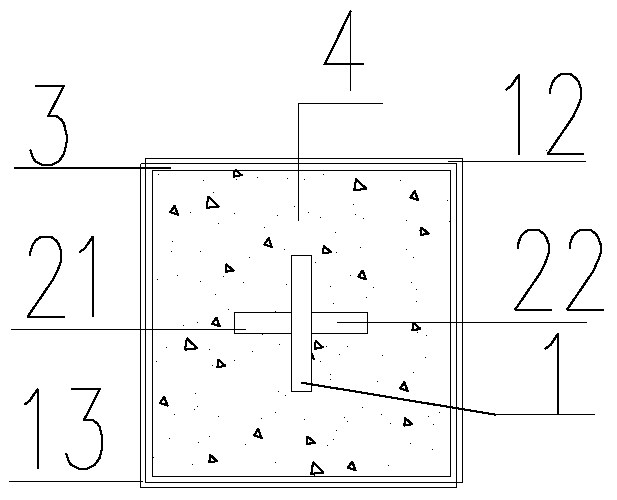

[0050] Embodiment 1 (all stress-bearing members are all in the form of full length):

[0051] see figure 1 As shown, it includes the main core force-bearing member 1 and the constraint member. The two ends of the main core force-bearing member 1 are respectively provided with a reinforced structural section, which is called the front non-yielding transformation section, the rear non-yielding transformation section, and the front non-yielding transformation section Including the first sub-core stress member 21, the rear non-yielding transformation section includes a second sub-core stress member 22, the restraint member includes a yield section restraint device for constraining the main core stress member 1, and a non-yielding transition section for constraining the front Left constraint for the segment, right constraint for the post-constraint non-yielding transition segment. The yield section constraint device includes a sleeve 3, a grouting material 4, and an end plate. The...

Embodiment 2

[0062] Embodiment 2 (all stress components are divided into three sections):

[0063] see Figure 8 As shown, in this embodiment, the main core force-bearing member, the first auxiliary core force-bearing member and the second auxiliary core force-bearing member are divided into three sections respectively, wherein the main core force-bearing member is composed of the main connecting plate 1 and the left main connecting plate 16 It is composed of the right main connecting plate 18; the first secondary core force-bearing member is composed of the first secondary connecting plate 21, the left secondary connecting plate 171 and the right secondary connecting plate 191, and the second secondary core force-bearing member is connected by the second secondary Plate 22, left two secondary connecting plates 172 and right two secondary connecting plates 192 form. The outer surface of the main connecting plate 1 is provided with non-adhesive material 21 .

[0064] The main connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com