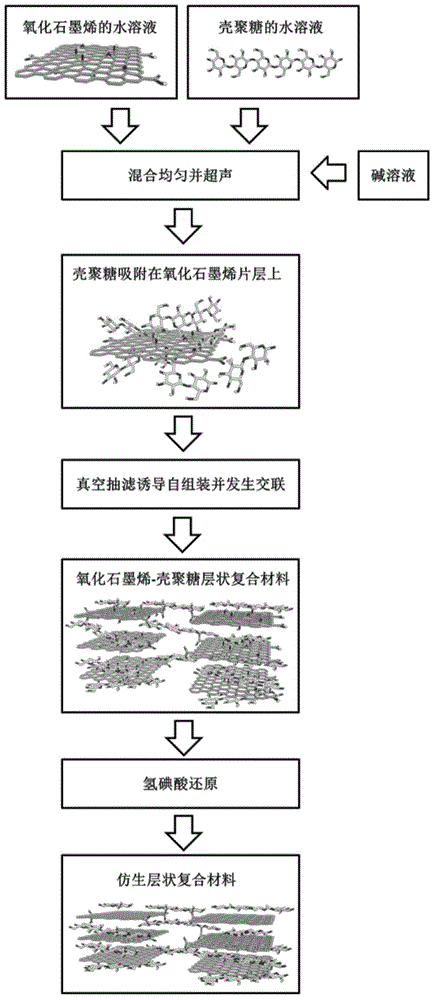

Preparation method of bionic layered tough integral conductive graphene composite material

A technology of composite materials and conductive graphite, which is applied in the field of preparation of biomimetic layered strong and tough integrated conductive graphene composite materials, can solve the problems of unreported biomimetic composite materials, etc., and achieve the effect of flexible and rich interface design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 10.5 mg of graphene oxide, mechanically stir and disperse it in 20 ml of deionized water, and then ultrasonically disperse for 20 minutes, resulting in a brown transparent solution. 0.45 ml of chitosan solution (mass fraction 1%) was added dropwise to the graphene oxide solution, and the stirring was continued. During this process, a brown-black gelatinous precipitate was precipitated. The heterogeneous suspension was ultrasonically treated for 5 minutes, adjusted to pH=8 with 0.5mol / L NaOH solution, and continued to be ultrasonicated for 10-15 minutes to obtain a uniformly dispersed graphene oxide-chitosan solution. The above solution is subjected to vacuum filtration to obtain a biomimetic layered graphene oxide composite material. During this process, due to the high content of chitosan, the ordered orientation of graphene sheets under the action of water flow was affected, so no chemical cross-linking occurred. Thermogravimetric analysis showed that the mass ...

Embodiment 2

[0034] Weigh 11.25 mg of graphene oxide, disperse it in 20 ml of deionized water with mechanical stirring, and then ultrasonically disperse it for 20 minutes, resulting in a brown transparent solution. 0.375 ml of chitosan solution (mass fraction 1%) was added dropwise to the graphene oxide solution, and the stirring was continued. During this process, a brown-black gelatinous precipitate was precipitated. The heterogeneous suspension was ultrasonically treated for 5 minutes, adjusted to pH=8 with 0.5mol / L NaOH solution, and continued to be ultrasonicated for 10-15 minutes to obtain a uniformly dispersed graphene oxide-chitosan solution. The above solution is subjected to vacuum filtration to obtain a biomimetic layered graphene oxide composite material. During this process, due to the high content of chitosan, the ordered orientation of graphene sheets under the action of water flow was affected, so no chemical cross-linking occurred. Thermogravimetric analysis showed that t...

Embodiment 3

[0036] Weigh 12 mg of graphene oxide, disperse it in 20 ml of deionized water with mechanical stirring, and then ultrasonically disperse for 20 minutes, resulting in a brown transparent solution. 0.3 ml of chitosan solution (mass fraction 1%) was added dropwise to the graphene oxide solution, and the stirring was continued. During this process, a brown-black gelatinous precipitate was precipitated. The heterogeneous suspension was ultrasonically treated for 5 minutes, adjusted to pH=8 with 0.5mol / L NaOH solution, and continued to be ultrasonicated for 10-15min to obtain a uniformly dispersed graphene oxide-chitosan solution. The above solution is subjected to vacuum filtration to obtain a biomimetic layered graphene oxide composite material. During this process, due to the high content of chitosan, the ordered orientation of graphene sheets under the action of water flow was affected, so no chemical cross-linking occurred. Thermogravimetric analysis showed that the mass fract...

PUM

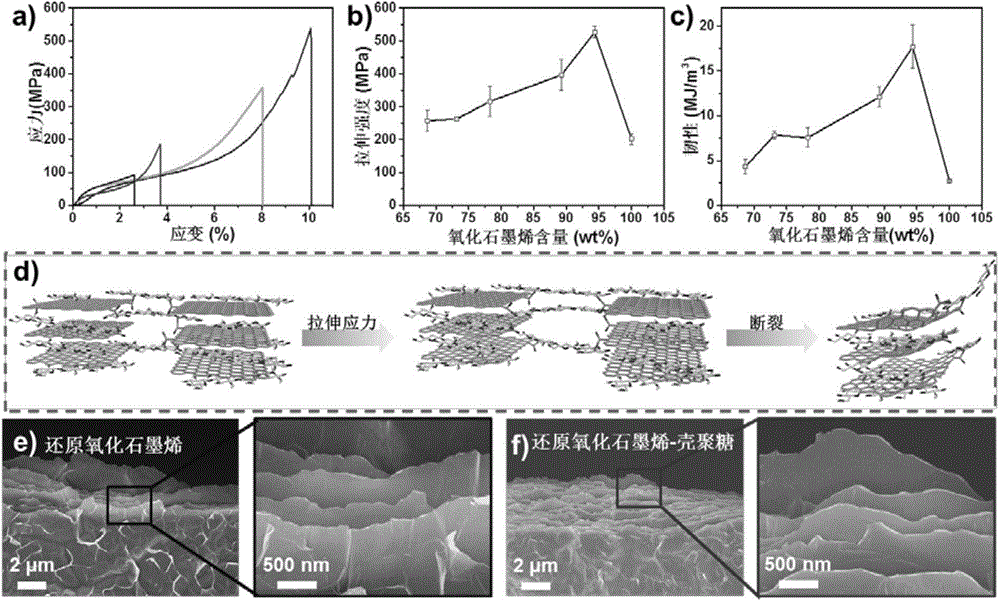

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com