An automated intelligent production method for preparing single-layer graphene

A single-layer graphene, intelligent production technology, applied in the field of graphene preparation, can solve the problems of immature technical process, no intelligent control, low graphene output, etc., to improve the image of clean production, stable product quality, and product quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

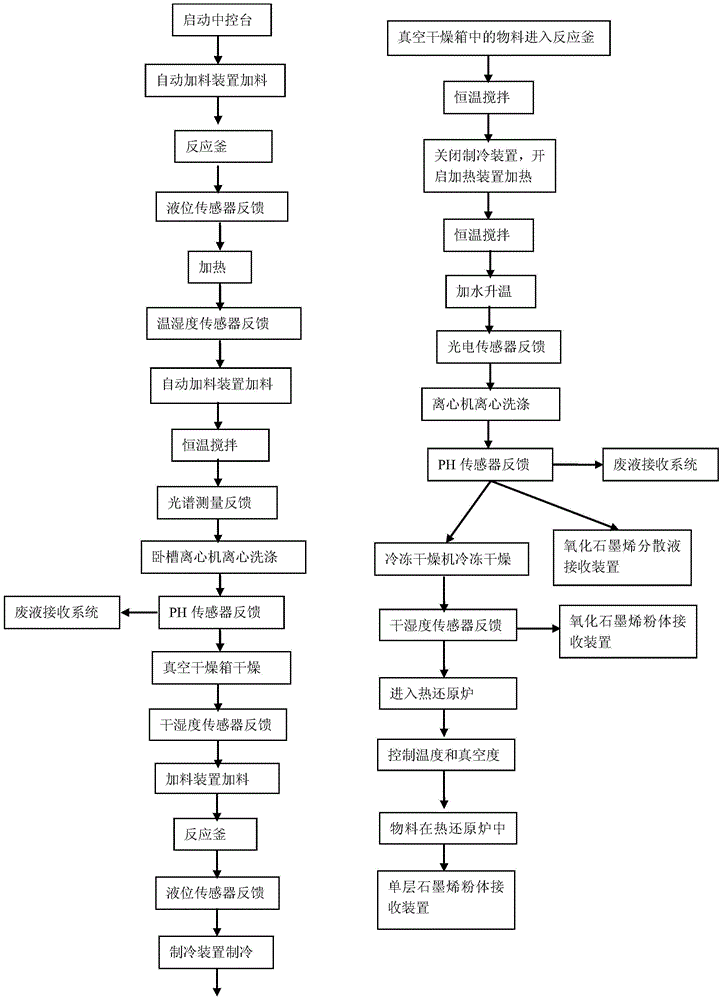

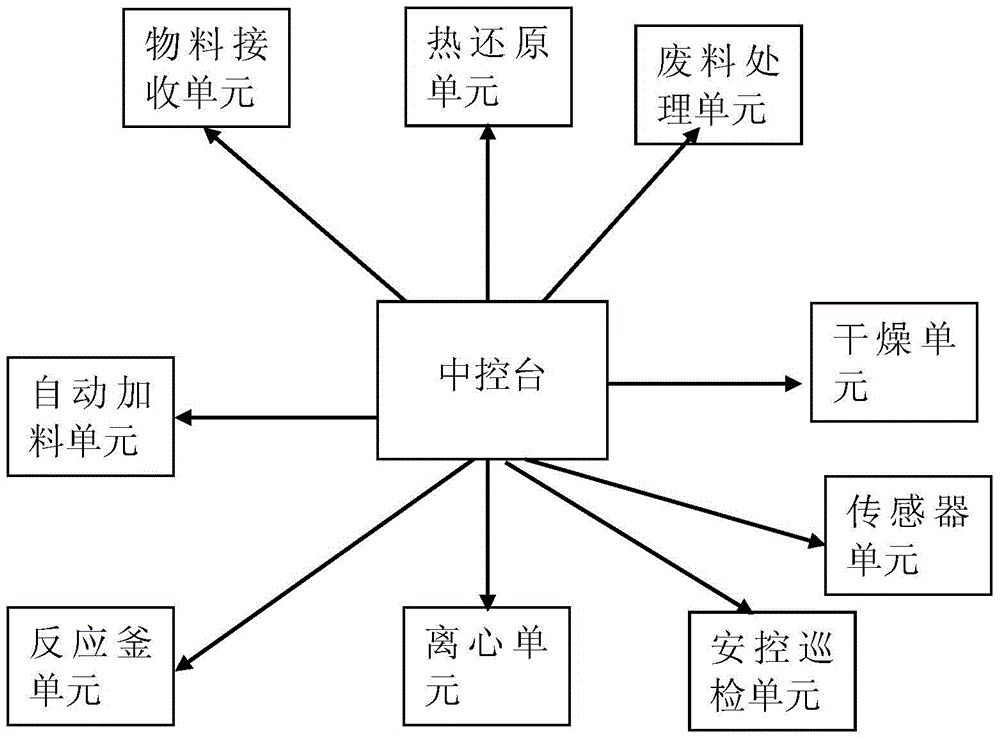

[0015] This embodiment is completed in the single-layer graphene automatic intelligent production equipment. The main structure of the single-layer graphene automatic intelligent production equipment is a central console, and the central console is composed of an automatic feeding unit, a reactor unit, a centrifugal unit, a drying unit, and a sensor. Unit, waste treatment unit, thermal reduction unit, material receiving unit and security inspection unit are composed of a combination. The automatic feeding unit automatically feeds materials into the reactor unit for reaction, and the reacted material enters the centrifugal unit for centrifugal washing, and the waste liquid passes through the waste The liquid treatment unit is discharged, the material after centrifugal washing enters the drying unit for drying, and the dried material enters the reactor unit to continue the reaction and then enters the centrifugal unit for centrifugal washing again, and the waste liquid is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com