Blow molding machine turning clip

A technology of blow molding machine and clamping arm, which is applied in the field of closing clips, which can solve the problems of easily polluted raw materials, insufficient stretching width, and small clamping force, and achieve the effects of avoiding pollution, increasing stretching width, and improving clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

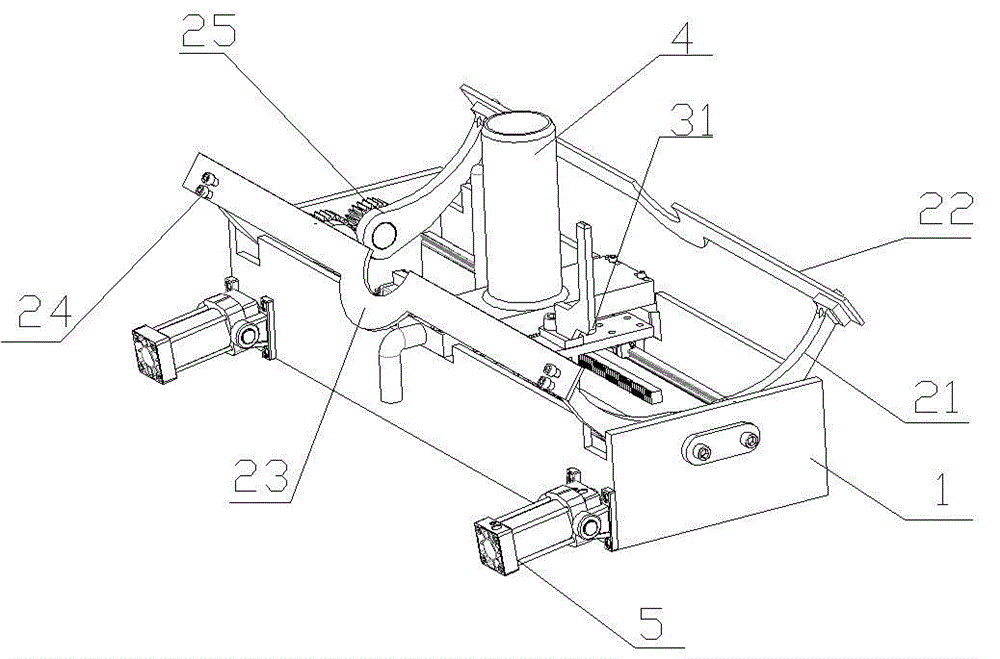

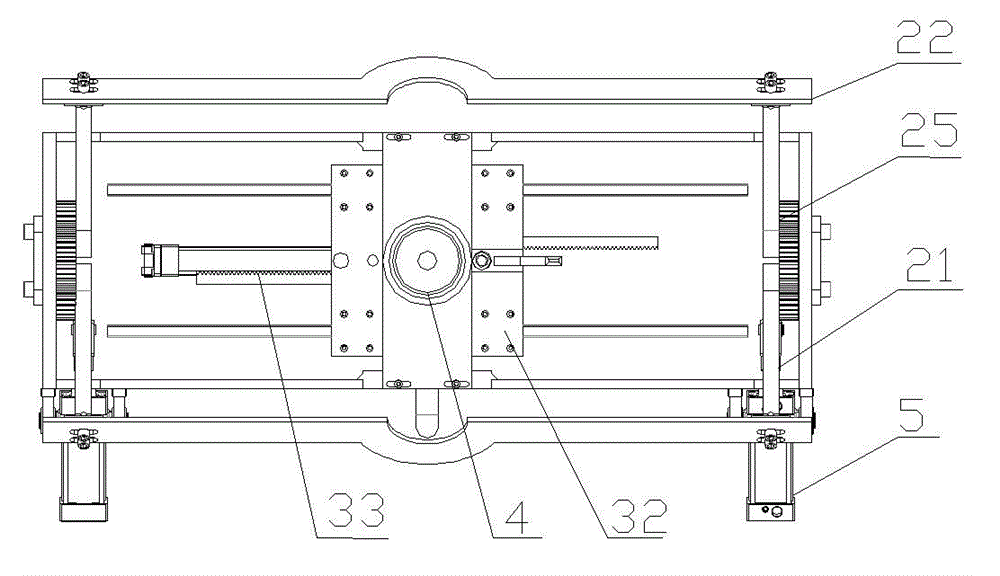

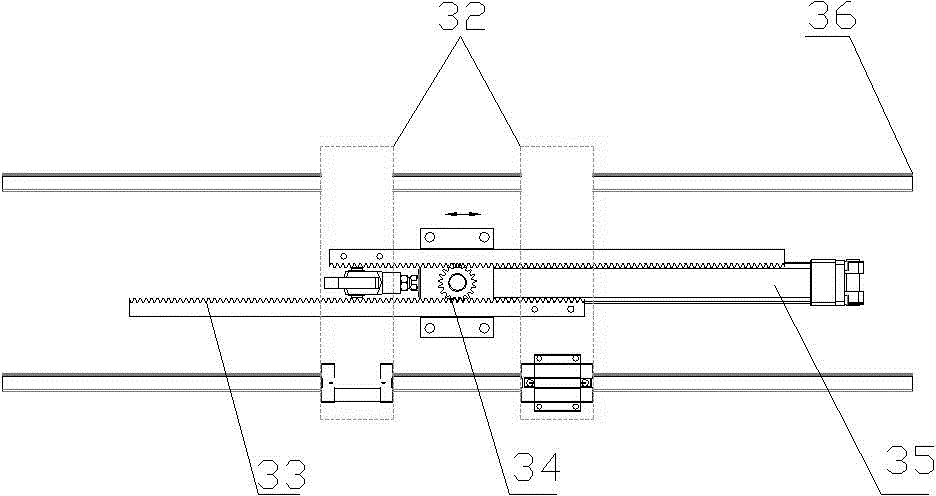

[0013] Such as figure 1 As shown, it includes chassis 1, clamp arm 21, clamp knife 22, bending part 23, bolt 24, gear 25, extension shaft 31, blow seat 4 and cylinder 5;

[0014] The present invention mainly comprises a base frame 1, two pairs of symmetrical clamping arms 21 are respectively arranged on the side walls at both ends of the base frame 1, and the clamping arms 21 are symmetrical arcs, which are arranged in an outwardly protruding arc shape, which can increase the The strength and power loss during the transmission process of the large clamp arms makes the closing more rapid; the bottom end of each clamp arm is respectively fixed on the side wall of the chassis 1 with two gears 25, and the two gears 25 are connected to each other. Impact, synchronous movement; one of each pair of symmetrical arc-shaped clamp arms 21 is connected to the cylinder 5, and the cylinder 5 pushes one of the clamp arms to rotate around the fulcrum, thereby driving the gear of the clamp arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com