Mould for one-piece base

A conjoined and molded technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of high cost, many leakage safety hazards, and many parts, and achieve high precision and ensure the verticality of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

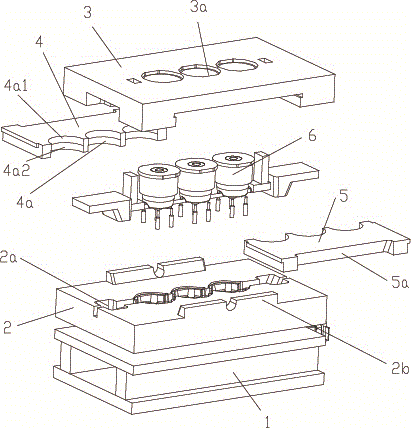

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 4 shown.

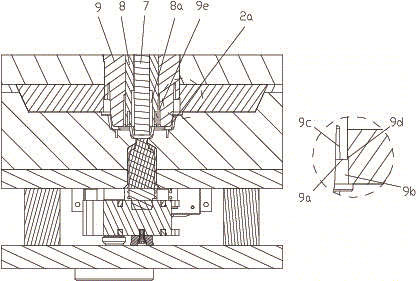

[0015] In order to describe the design advantages of this mold more clearly and better, a special addition Figure 4 Schematic diagram of the product structure, the one-piece base includes base a, inner ring b, middle ring c, outer ring d, water inlet e and water outlet f, and the outer ring is divided into the first step g, the second step h and the third step Step i, the outer periphery of the step surface of the second step is provided with a circle of convex ring j.

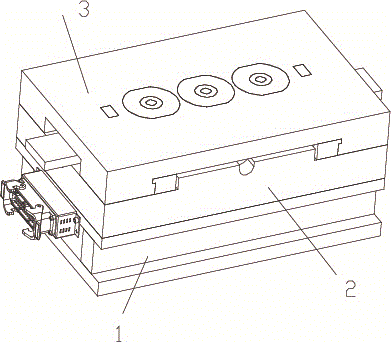

[0016] The mold of the one-piece base includes a mold base 1, a lower template 2, an upper template 3, a left template 4 and a right template 5, the left template and the right template are sandwiched between the upper template and the lower template, and the upper template is provided with three circular holes 3a , three semicircular not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com