All-side rotation clamp based flexible production workstation for automobile welding production line

A welding production line, four-sided rotation technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of switching production without the left and right side walls, waste of space, multiple labor and equipment costs, and save welding space. , the effect of improving the working environment and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

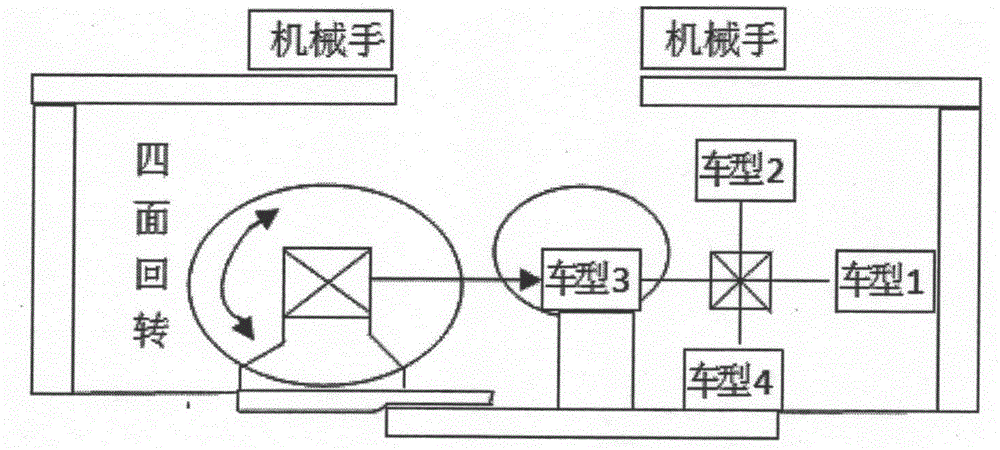

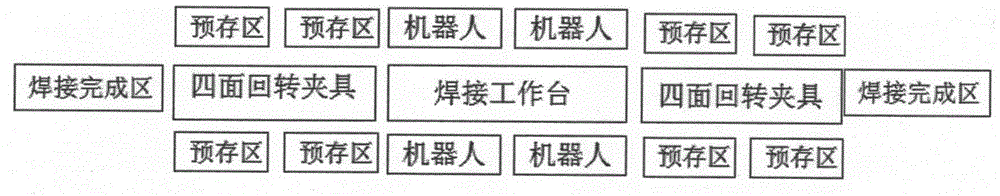

[0018] combine figure 1 and figure 2 , the present invention provides a flexible production workstation for automobiles that can meet the flexible production requirements for welding of various vehicle types by using four-axis revolving fixtures on the left and right sides of the production workstation. The invention includes a welding station located in the middle of the production station. The welding workbench is divided into the frame workbench workstation position, the middle position of the workbench and the switch position of the workbench, and the three positions are driven by stepping motors. There are four welding robots arranged on both sides of the welding workbench, two on each side. A four-sided rotary fixture is arranged on each side connecting the left and right sides of the welding workbench. The four-sided rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com