Automatic classifying, residue removing and cleaning system for tableware and using method

An automatic sorting and cleaning system technology, applied in the field of cleaning, can solve the problems of difficult technical guarantee, combination of tableware recycling and cleaning and disinfection steps, and inability to clean up leftovers in time, so as to reduce the intermediate manual handling stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

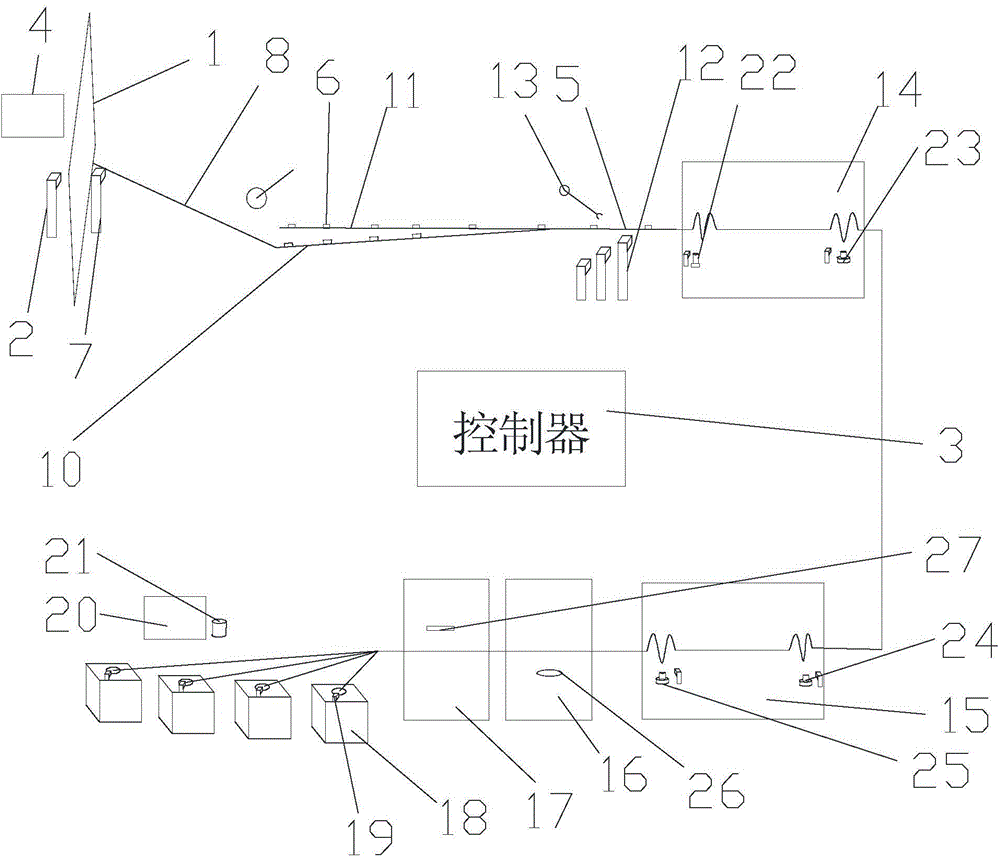

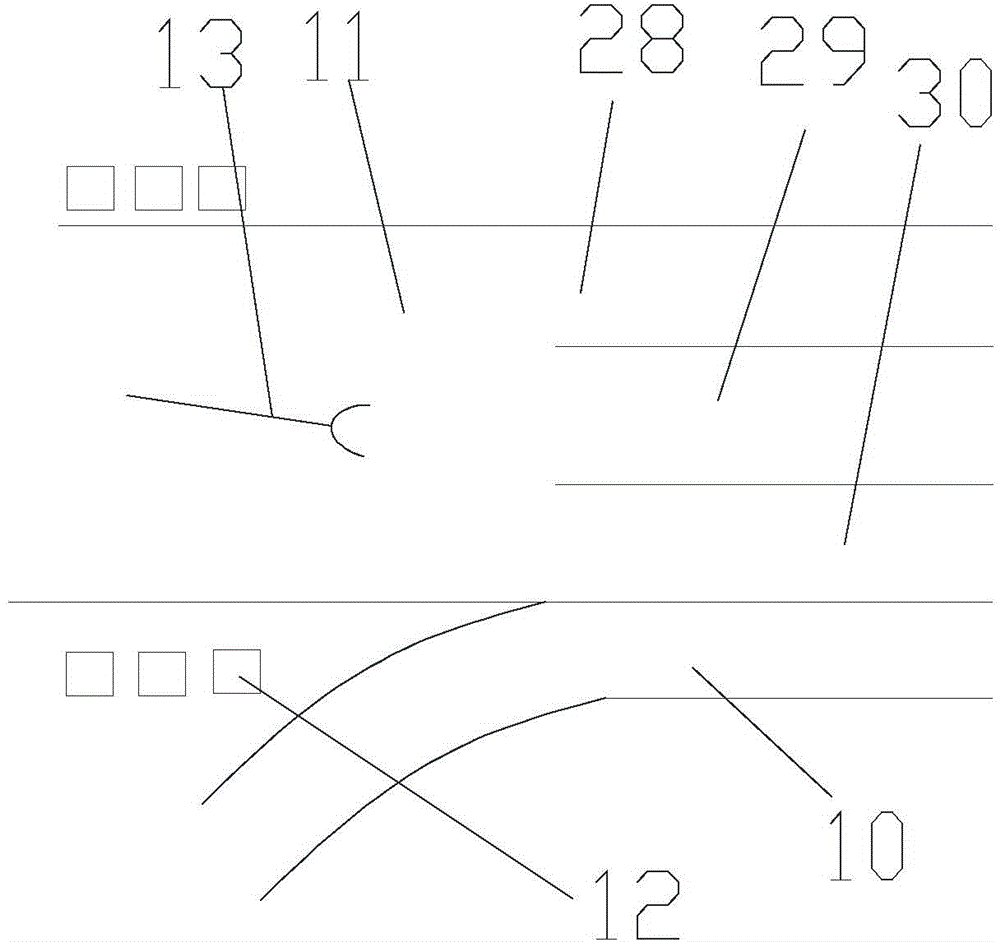

[0045] Such as figure 2 and image 3 The shown automatic tableware sorting, slag removal and cleaning system includes an opening valve 1. The opening valve 1 is provided with a first infrared sensor 2 and an inclined plate 8 for detecting the number of tableware. The first infrared sensor 2 is connected to a control system operating A controller 3, the controller 3 is connected with a first capacity display screen 4 for displaying the quantity of tableware; the opening valve 1 is connected with a swingable inclined plate 8, and above the inclined plate 8 is provided with a rolling brush booster 9 for separating dishes; The front end of the plate 8 is provided with a second infrared sensor 7 for measuring the height of the edge angle of the dinner plate, and the second infrared sensor 7 is connected to the controller 3; the inclined plate 8 is connected to a track 5, and the track 5 is provided with an electrostatic chuck for absorbing tableware 6. The track 5 includes a plat...

Embodiment 2

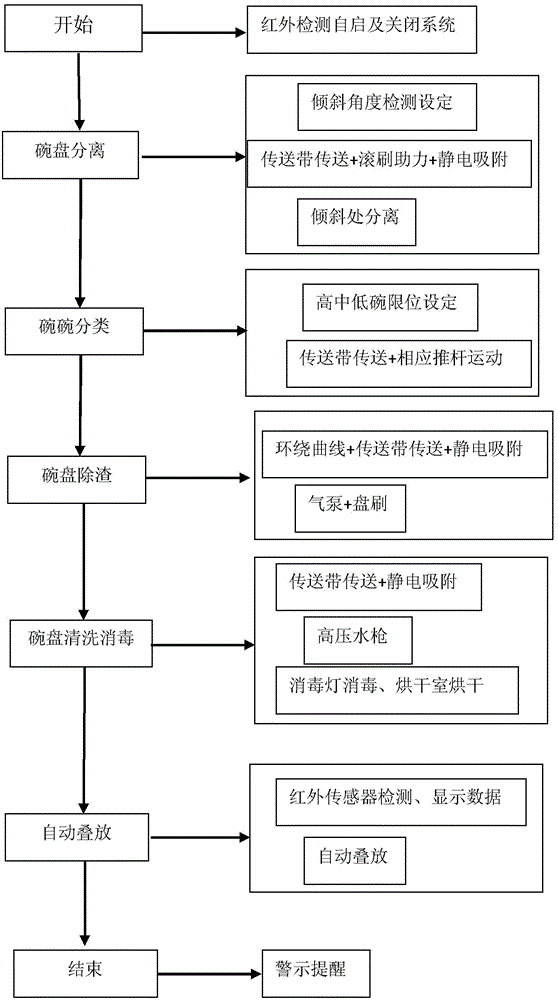

[0049] Such as figure 1 A method for using the tableware automatic classification, slag removal and cleaning system includes the following steps:

[0050] Step 1) Separation of dishes: Pour the tableware to be cleaned into the cleaning system from the opening valve 1; the first infrared sensor 2 detects the entry of the tableware, and transmits the tableware quantity information and indication signal to the controller 3; the controller 3 controls the cleaning The system is turned on, and the number of tableware is displayed on the first capacity display screen 4; the second infrared sensor 7 detects the height information of the plate edge angle and transmits it to the controller 3, and the controller 3 controls the tilting plate 8 to swing to form the best separation angle. The roller brush booster 9 above the inclined plate 8 pushes the bowl to the bowl track 11, and the bowl enters the bowl track 10 through a gap formed between the bowl track 10 and the bowl track 11; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com