Bread maker

A kind of bread machine, the technology of rolling noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

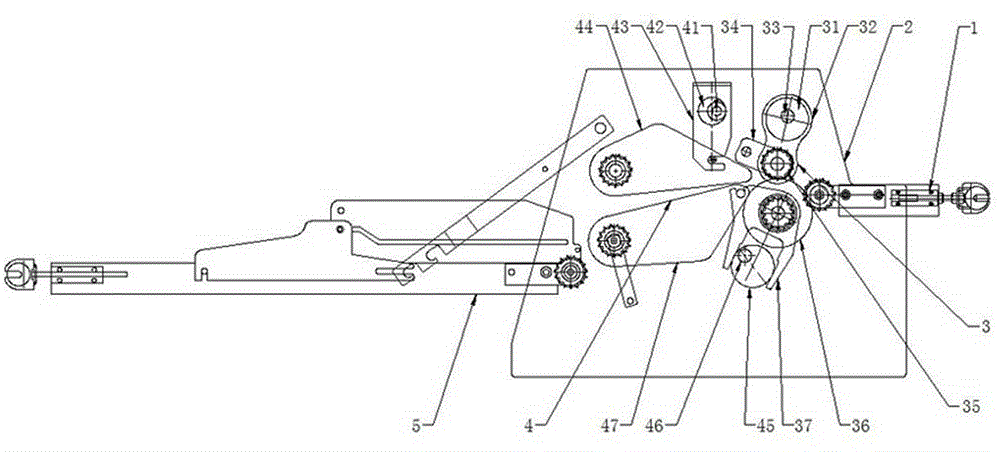

[0010] refer to figure 1 , the specific embodiment adopts the following technical solutions: it is composed of a face-feeding conveyor frame 1, a wallboard 2, a pre-press roller assembly 3, a rolling noodle belt assembly 4 and a finished product conveyor frame 5, and the face-feeding conveyor frame 1 and the wallboard 2 Connection, the wallboard 2 is provided with a pre-pressing roller assembly 3 and a rolling noodle belt assembly 4, and the wallboard 2 is connected with the finished product delivery frame 5.

[0011] The pre-compression roller assembly 3 includes an eccentric disk 31, an eccentric disk connection sleeve 32, an upper pressure roller adjustment shaft 33, an upper pressure roller connecting rod 34, an upper pre-compression roller 35, a lower pre-compression roller 36, a shift fork 37, and an eccentric The disk 31 is provided with an eccentric disk connection sleeve 32, and an upper pressure roller adjustment shaft 33 is arranged in the middle. The eccentric disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com