Remote control type universal wire clamp

A technology of remote control and clamping clamps, which is applied in the direction of electrical connection sockets, etc., which can solve problems such as potential safety hazards and difficulties in changing the direction of clamping wires, and achieve the effect of improving the safety index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

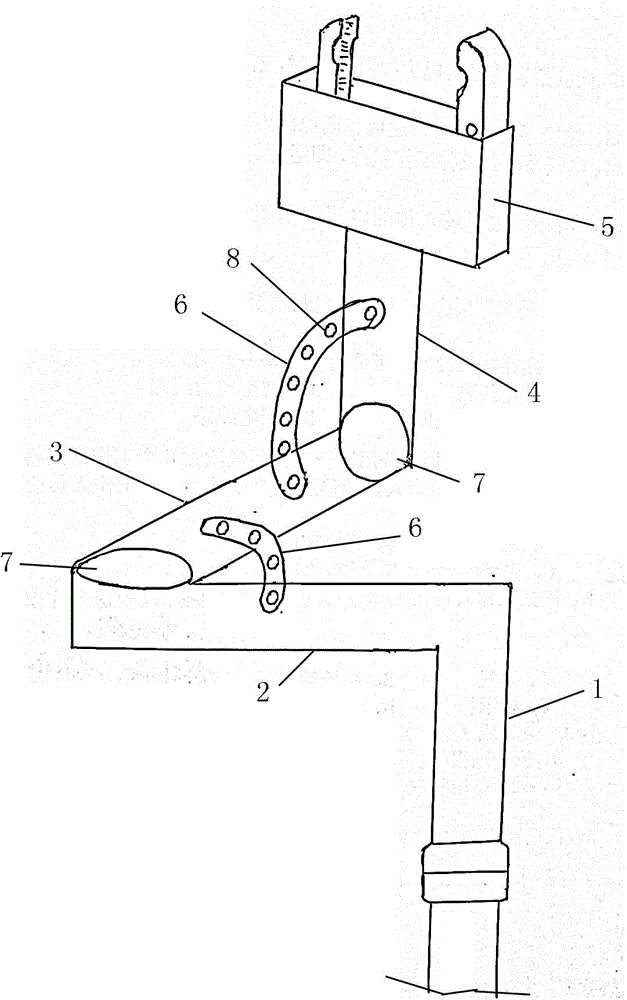

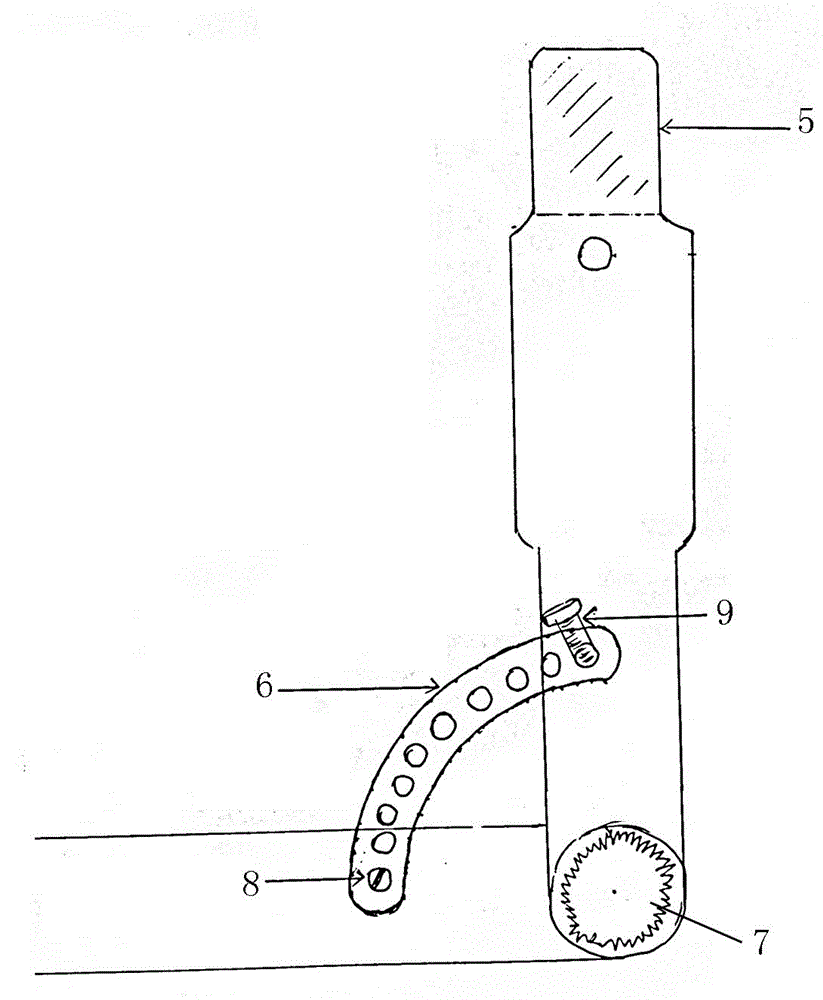

[0029] Such as Figure 1-4 As shown, it includes an operating rod 1, a horizontal rod 2, a connecting rod 3, a support rod 4, a chuck 5 and a limit frame 6. The top end of the operating rod is connected to one end of the horizontal rod, and the other end of the horizontal rod is connected to the connecting rod through the rotating shaft 7. One end of the connecting rod is connected, the other end of the connecting rod is connected to one end of the supporting rod through the rotating shaft, and the other end of the supporting rod is connected to the chuck. A horizontal limit frame is arranged between the horizontal rod and the connecting rod. A vertical limit frame is arranged between them.

[0030] Described limit frame is made up of arc-shaped limit plate, limit hole 8 and adjusting screw 9, limit hole is evenly spaced on the limit plate, and adjusting screw is set on the limit hole movably, and the outer diameter of adjusting screw and The inner diameter of the limit hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com