Novel shore durometer

A Shore hardness tester, a new type of technology, applied in the direction of testing material hardness, etc., can solve the problem of reducing measurement accuracy and achieve the effect of increasing measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

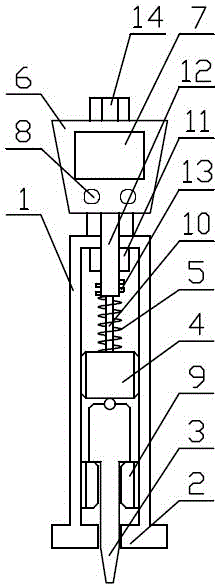

[0011] The present invention includes a housing 1, a press foot 2, a press needle 3, a slider 4, a spring 5, a control panel 6, a display screen 7, a control button 8, a press needle fixing ring 9, an electronic telescopic measuring ruler 10, a mounting nut 11, Adjusting screw rod 12, grille 13, adjusting nut 14, the lower end of housing 1 is presser foot 2, and spring 5 is set on the outside of electronic telescopic measuring ruler 10 at first during installation, then the lower end of telescopic measuring ruler and spring 5 is connected with sliding The block 4 is connected, and the adjusting screw rod 12 is provided with a grille 13, the upper end of the telescopic measuring ruler is connected with the adjusting screw rod 12, the upper end of the spring 5 is stuck on the grille 13 and connected with the adjusting screw rod 12, and then the mounting nut 11 is installed On the top of the inside of the housing 1, thread the upper end of the adjusting screw 12 through the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com