Guide structure and installation method used for installation of light wall boards

A technology of lightweight wall panels and an installation method, which is applied in building construction, building material processing, construction, etc., can solve the problems of inconvenient splicing of lightweight wall panels, and achieve the advantages of convenient splicing, cost saving and utilization rate improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

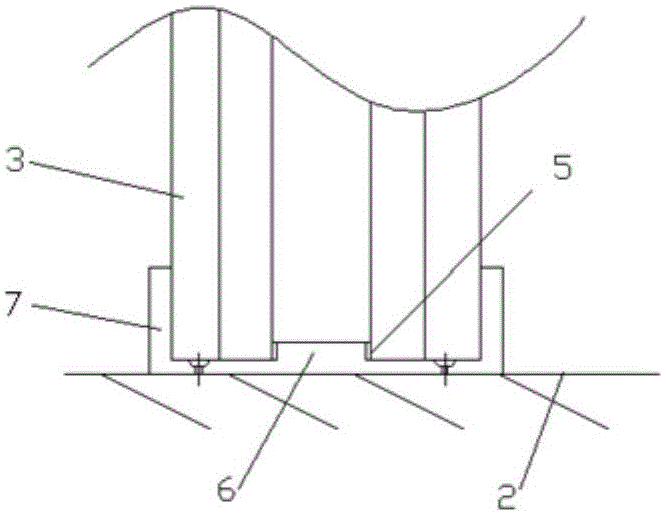

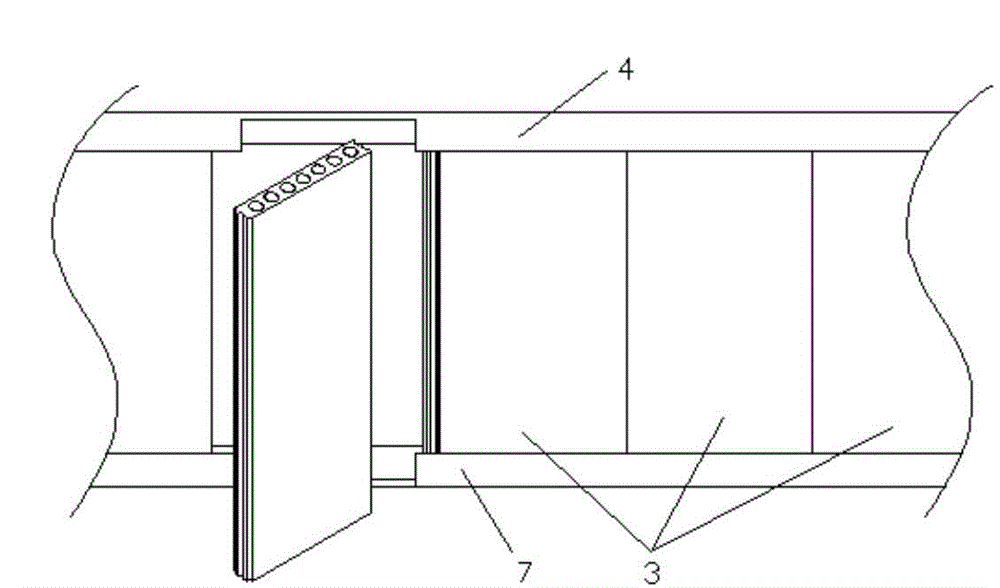

[0019] The present invention provides a support structure for installing lightweight wall panels 3, such as figure 1 As shown, on the bottom surface of the upper floor 1 and the surface of the lower floor 2, an upper guide rail 4 and a lower guide rail 7 are correspondingly arranged along the laying direction of the lightweight wallboard 3 , and the upper guide rail 4 and the lower guide rail 7 are provided with guide rails for installation and Limit the opening of the lightweight wall panel 5 position. Among them, the opening widths of the upper guide rail 4 and the lower guide rail 7 are 5-20 mm larger than the thickness of the light wall panel 3. In this way, the smooth operation of the light wall panel 3 and the alignment of the guide rails are ensured. Limitation of verticality of lightweight wall panels 3.

[0020] The cross-section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com