Cylinder decoration strip assembly

A technology of decorative strips and columns, applied in covering/lining, construction, building construction, etc., can solve the problems of potential safety hazards, easy loosening or falling off of boards, etc., and achieve the effect of increasing safety and reliability and stabilizing the fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

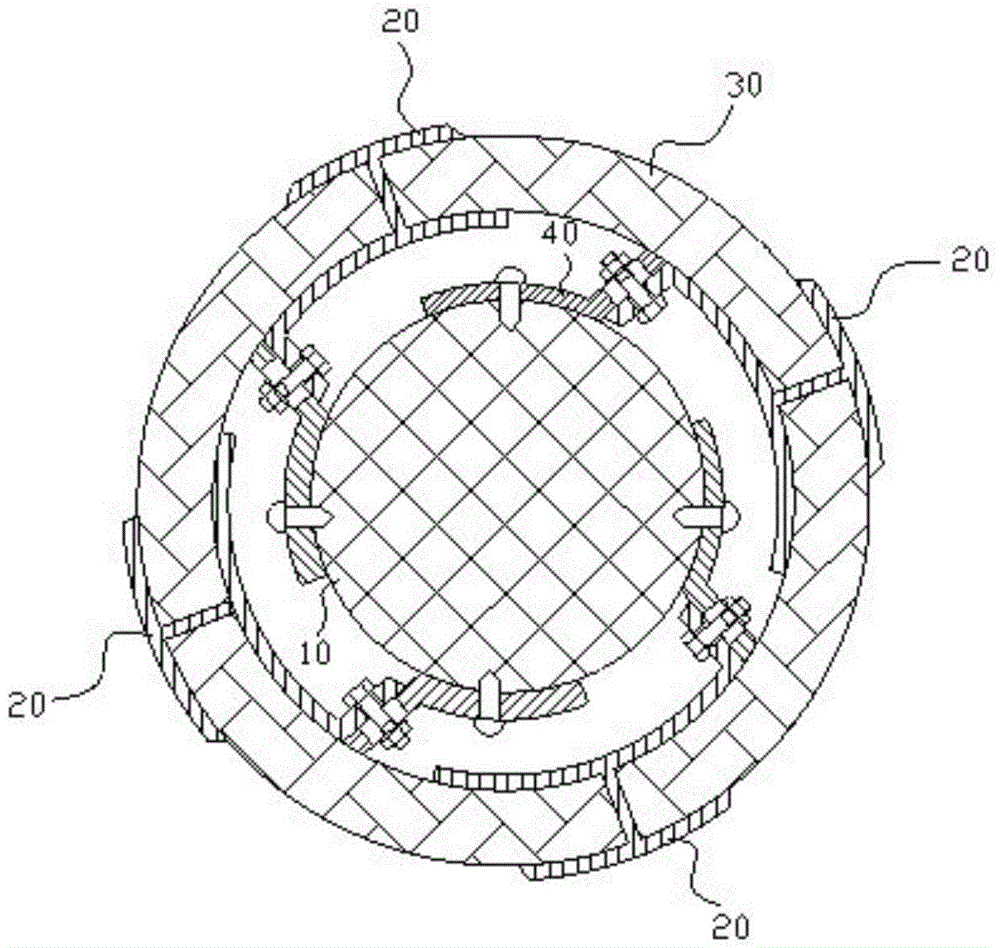

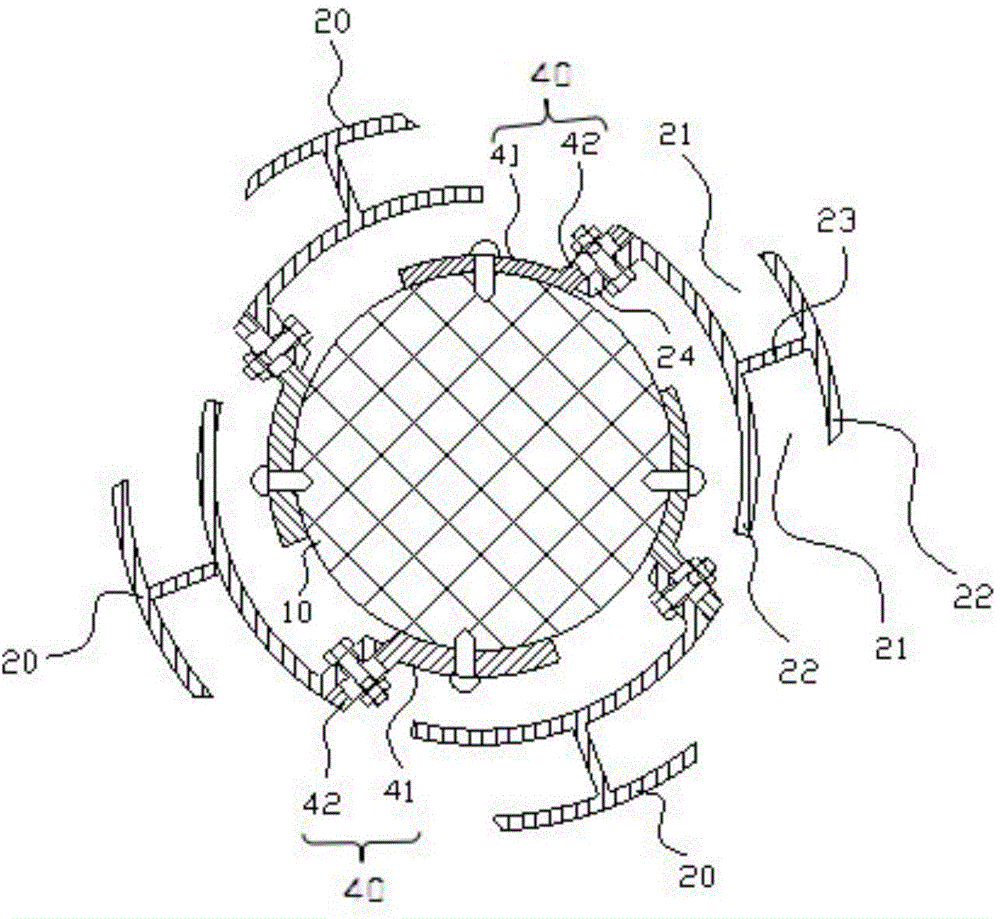

[0008] A cylindrical decorative strip assembly, including clamping parts 20 arranged at intervals along the circumference of a cylinder 10, the clamping part 20 is provided with a clamping part 21 for clamping a decorative panel 30, and the clamping part 20 is fixed and suspended on the cylinder 10 for the exterior. This technical solution is to use a plurality of clips 20 to fix the decorative plate 30 on the outside of the cylinder 10 in an indirect manner. The clips 20 can be fixed on the outside of the cylinder 10 by welding or screwing. It is relatively stable, and the corresponding decorative board 30 will also be firmly fixed, so the safety is relatively high.

[0009] As a further preferred solution: the clamping member 20 includes two curved plates 22 arranged at intervals, the center of curvature of the curved plates 22 coincides with the axis of the cylinder 10, and a radial line is connected between the two curved plates 22 The connecting plate 23 arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com