Floating floor structure for sound insulation and vibration reduction of buildings

A floating floor and building technology, applied in the direction of building components, building structures, floors, etc., can solve the problems that it is difficult to achieve air sound, floor impact sound cannot meet the sound insulation requirements of residential buildings, and improve the performance of air sound insulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

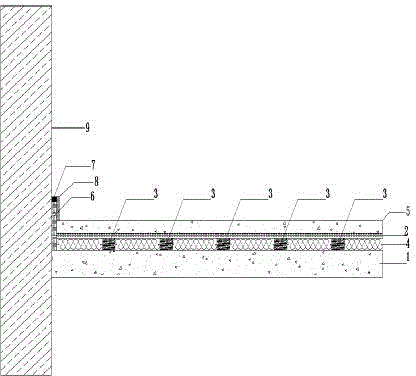

[0016] Such as figure 1 As shown, in an intercontinental hotel project, the guest room floor is cast-in-place reinforced concrete floor slab, the thickness is 140mm, and the surface flatness of the structural floor slab is ≤5mm. There are frequent activities on the top of the guest room, and the impact of noise and vibration is relatively large. The floating floor structure is adopted for building sound insulation and vibration reduction to meet the design index requirements of the floor acoustic environment.

[0017] The upper surface of the floor 1 is equidistantly arranged with elastic damping units 3. The elastic damping units are vibration-isolation rubber pads. According to the load statistics on the upper part of the floor, the vibration-isolation rubber pads are selected as independent modules with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com