Raw material carrying trolley capable of walking automatically

A technology for moving trolleys and moving automatically, which is applied in transportation and packaging, conveyors, mechanical conveyors, etc., and can solve problems such as the inability of the trolley to stop steadily, affect production efficiency, and jolting of the trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

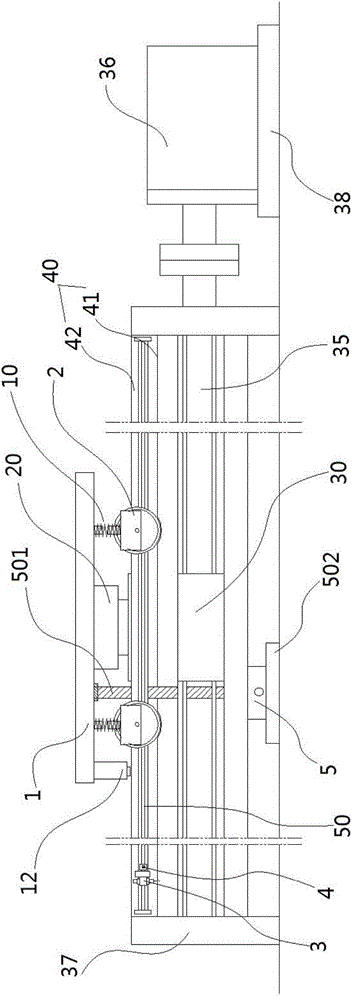

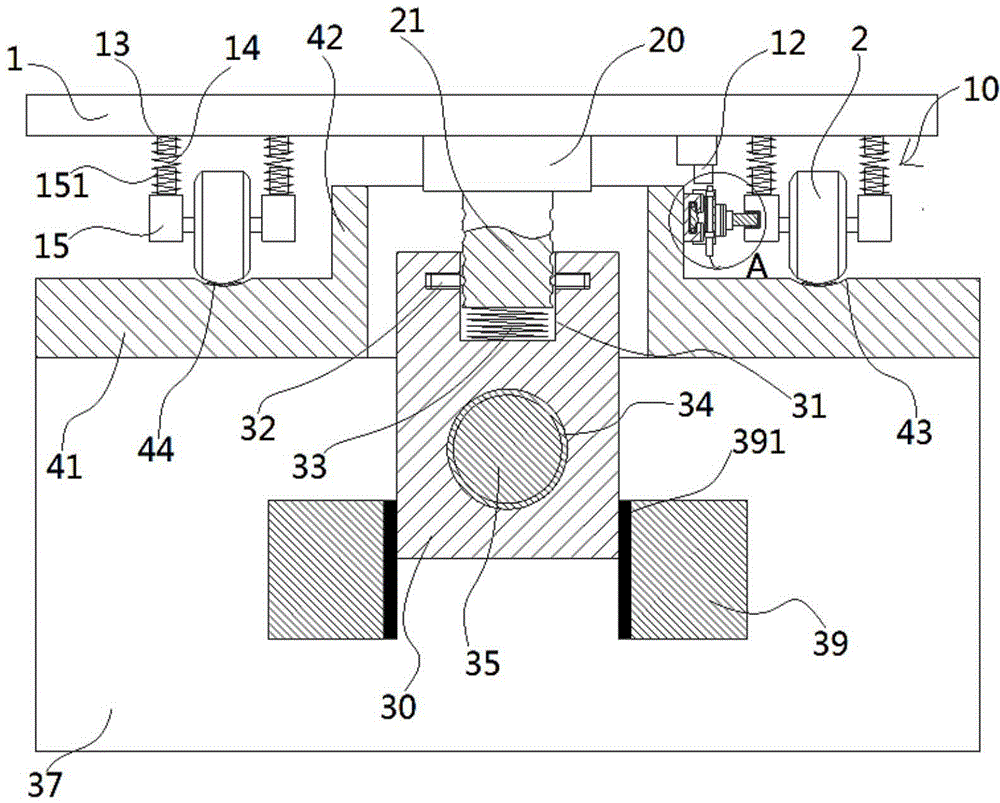

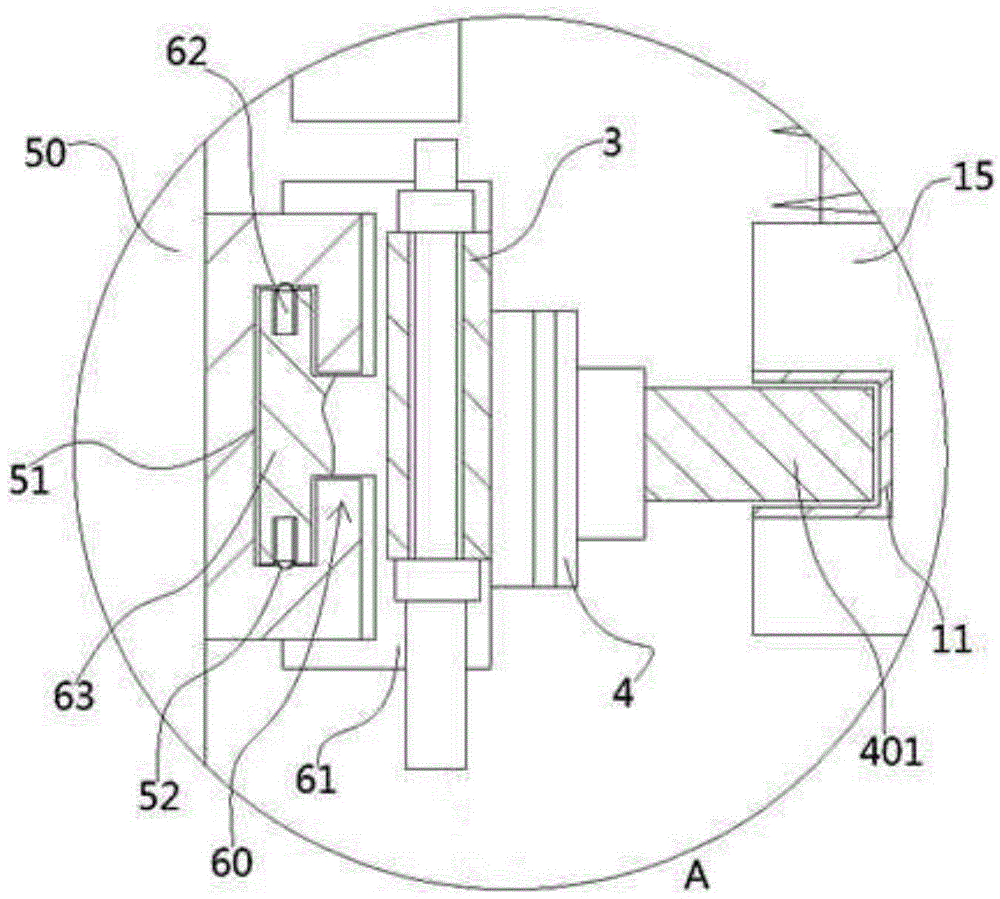

[0030] see Figure 1 to Figure 7 The self-propelled raw material handling trolley of the present invention includes a material plate 1, the bottom surface of the material plate 1 is connected with at least two walking wheels 2 through a buffer mechanism 10, and a movable connection block is fixed in the middle of the bottom surface of the material plate 1 20. The middle part of the bottom surface of the mobile connection block 20 has an insertion part 21, and the insertion part 21 is inserted into the insertion hole 31 provided on the walking block 30 under the material plate 1. The insertion hole 31 A connecting ball plunger 32 is screwed on the inner wall, and the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com