Manual screw type tension device applied to waste treatment of pickling line inlet

A technology of waste material treatment and tensioning device, which is applied in the direction of transportation, packaging, and conveyors. It can solve the problems of insufficient length of guide rails on both sides, frequent slippage of drive rollers, deformation and elongation of belts, etc., and reduce the accident rate and spare parts costs. , Solve the effect of poor operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

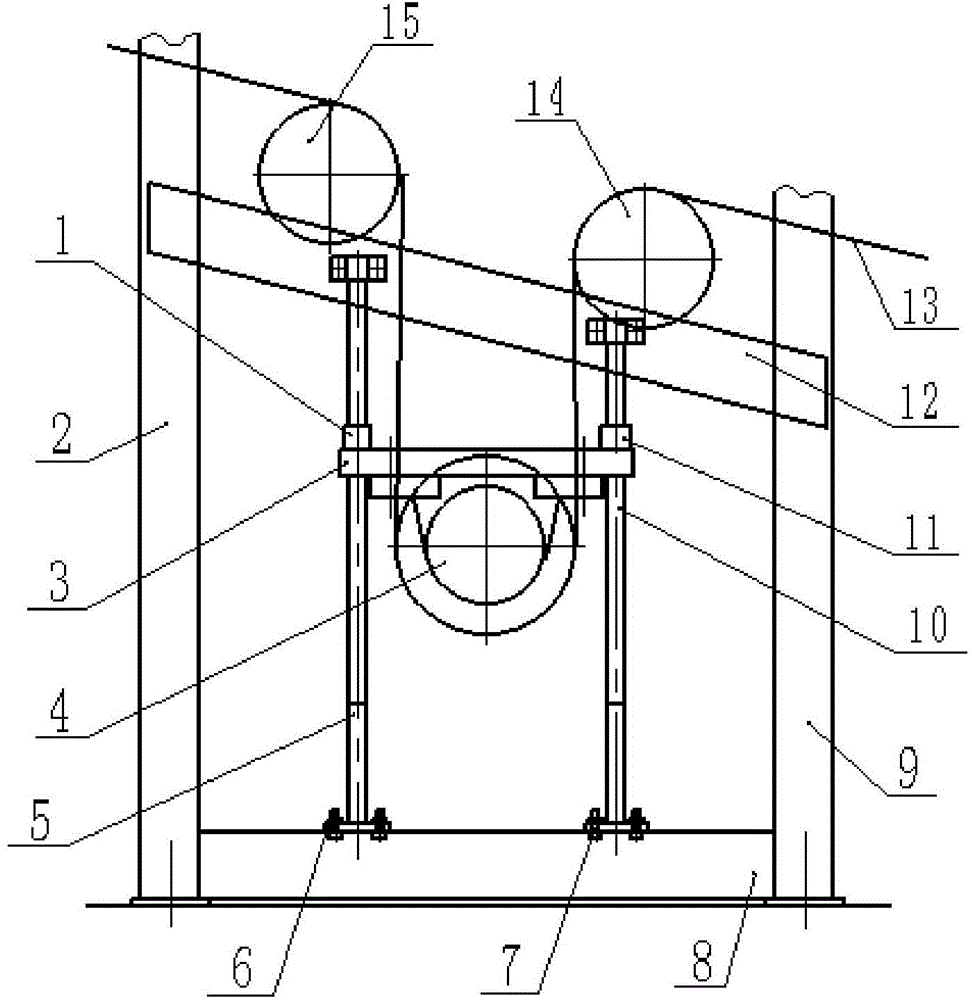

[0016] Examples, see attached figure 1 , a manual screw tensioning device for waste treatment at the pickling line inlet, comprising a left adjusting nut 1, a left column 2, a bearing seat 3, a weight roller 4, a left adjusting screw 5, a nut 6, a bolt 7, a fixing Support 8, right column 9, right adjusting screw rod 10, right adjusting nut 11, inclined support 12, belt 13, right redirecting roller 14 and left redirecting roller 15, it is characterized in that, described fixed bracket 8 left ends are welded and installed on the left On the column 2, its right end is welded and installed on the right column 9, the left end of the inclined bracket 12 is fixedly installed on the left column 2, and its right end is fixedly installed on the right column 9, and the lower end of the left adjusting screw rod 5 passes through the bolt 7 and the nut 6 is fixedly installed on the fixed bracket 8, and its upper end is fixedly installed on the inclined bracket 12. The left adjusting nut 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com