Overall manufacture method for forecastle bulwark of ship

A technology of integral fabrication and bulwark, applied in ship parts, ship construction, ships, etc., can solve problems such as increased workload, hoisting distortion of bulwark panels, long length, etc., to improve accuracy and quality, shorten construction period, reduce Making Difficulty Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for making the forecastle bulwark of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples, in order to understand the application process of the method of the present invention more clearly, but it cannot be used to limit the protection of the present invention scope.

[0031] The present invention has carried out research on the manufacturing method of the bulwark on the basis of the prior art, tries to reduce the difficulty of making the forecastle bulwark with a new operation method, and converts high-altitude operations into low-altitude operations as much as possible; the bulwark can be separated from the forecastle division. section, so that the bulwark and the hull can be built in parallel, shortening the construction period of the entire ship.

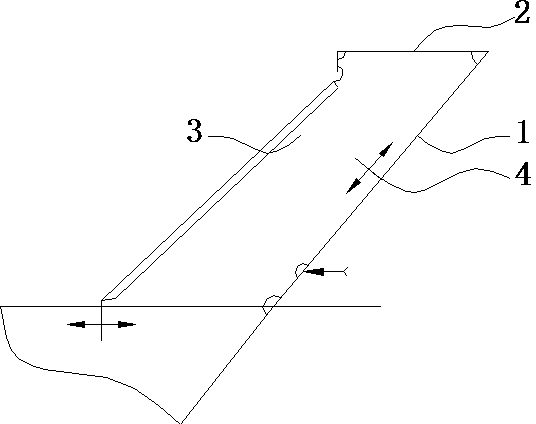

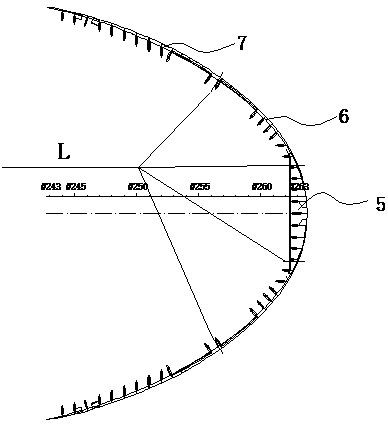

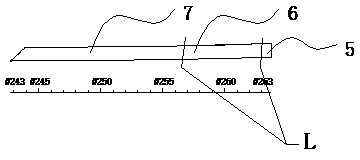

[0032] Such as figure 2 with image 3 As shown, the structure of the forecastle bulwark of the ship includes a bulwark plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com