A Fault Tolerant Planning Method for Acceleration Layer of Redundant Manipulator

An acceleration and manipulator technology, applied in the field of redundant manipulator fault-tolerant planning and control, it can solve the problems of inability to avoid obstacles and eliminate manipulators, achieve obstacle avoidance, eliminate the possibility of physical damage, In-depth and rigorous effect of the derivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

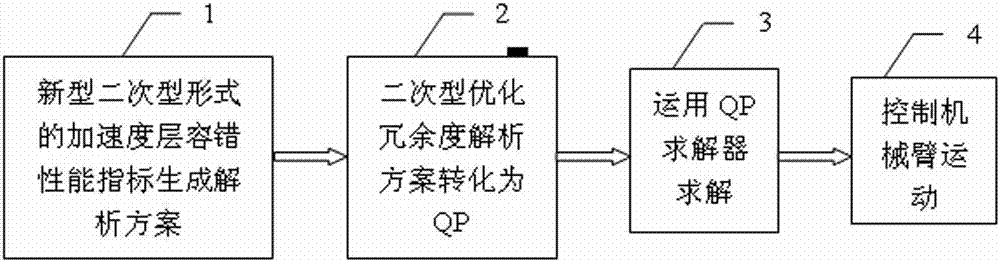

[0025] Such as figure 1 As shown, the fault-tolerant planning method of the redundant manipulator of the present invention first proposes the fault-tolerant performance index and constraints of the acceleration layer; then converts it into a corresponding QP; then applies the QP solver to solve; finally, the lower computer controller controls the Movement of the robotic arm.

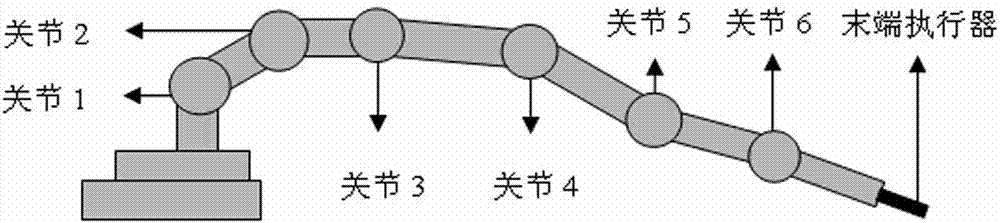

[0026] See figure 2 As shown, the mechanical arm realizing the present invention is a planar six-link mechanical arm;

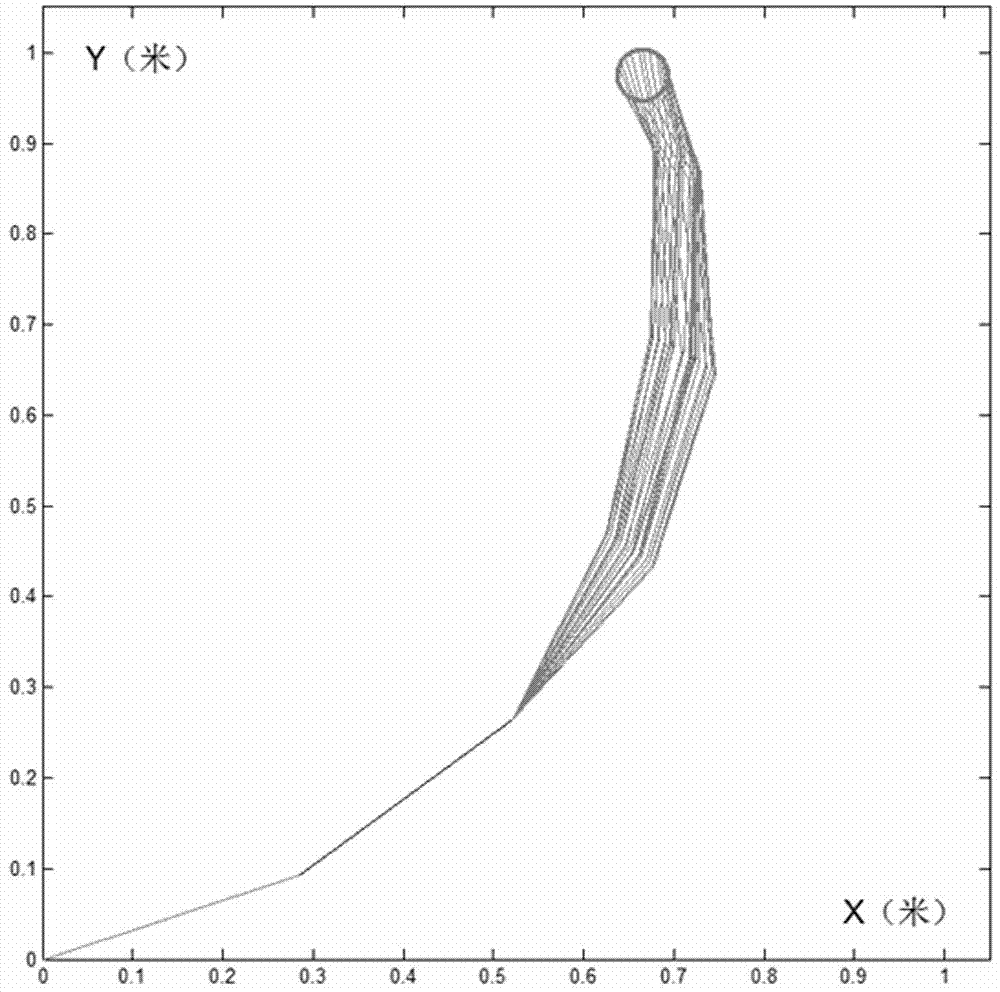

[0027] See image 3 As shown, it is a fault-tolerant schematic diagram of a planar six-link manipulator; a given terminal task is to draw a planar circle, and when both joints 1 and 2 fail to lock, the other joints will be adjusted to the optimal trajectory in time to ensure that the mechanical The end of the arm performs the task of drawing a circle.

[0028] See Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com