A kind of template marking crimping device and using method thereof

A model marking and pressing bar technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed processing quality, low production efficiency, easy injury, etc., to eliminate arm soreness and reduce workload , the effect of reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

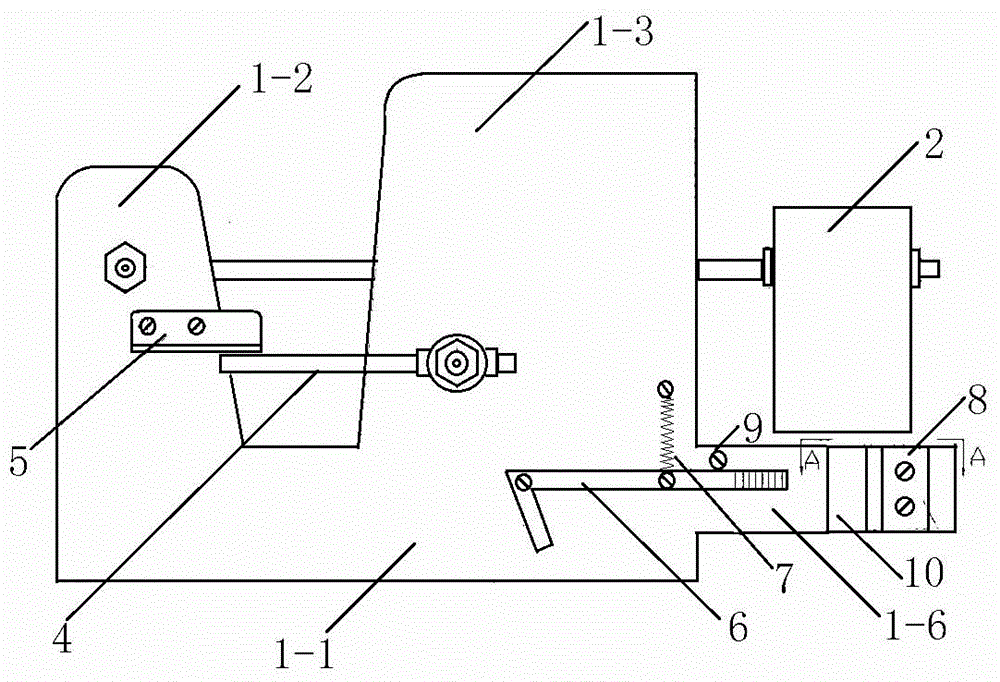

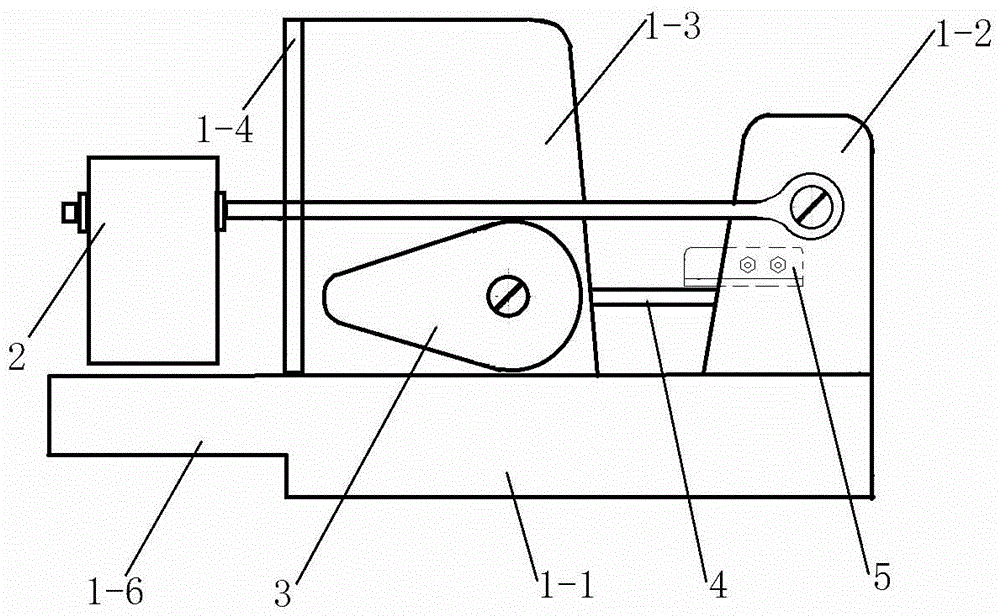

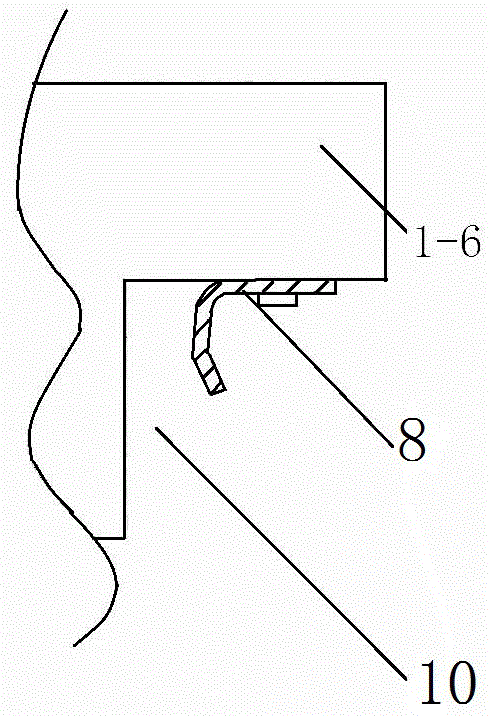

[0018] Such as Figure 1-3 Shown, a kind of template marking pressing device is characterized in that: it includes components, the lower part of which is a base 1-1, and the fixing plate 1-6 is connected to the side of the base 1-1 and protrudes along the horizontal plane, and its lower bottom surface Higher than the bottom surface of the base 1-1, a terminal support arm 1-2 is vertically arranged at the end of the base 1-1 away from the fixed plate 1-6, and the support arm 1-3 is arranged between the terminal support arm 1-2 and the fixed plate Between 1-6, a baffle plate 1-4 is provided on the side of the support arm 1-3, and a limiting groove is opened on the baffle plate 1-4.

[0019] One end of the hammer shaft of the power hammer 2 is rotatably connected to the end support arm 1-2, and the other end is connected to the hammer head through the limit groove; The position welding round bar passes through the support arm 1-3 and is connected on the end support arm 1-2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com