Pressure sensing structure, electronic equipment border and mobile electronic equipment

A pressure and sensor technology, applied in electrical digital data processing, instruments, digital data processing parts, etc., can solve the problems of large thickness space, increase production cost, occupy products, etc., to save thickness space and reduce installation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

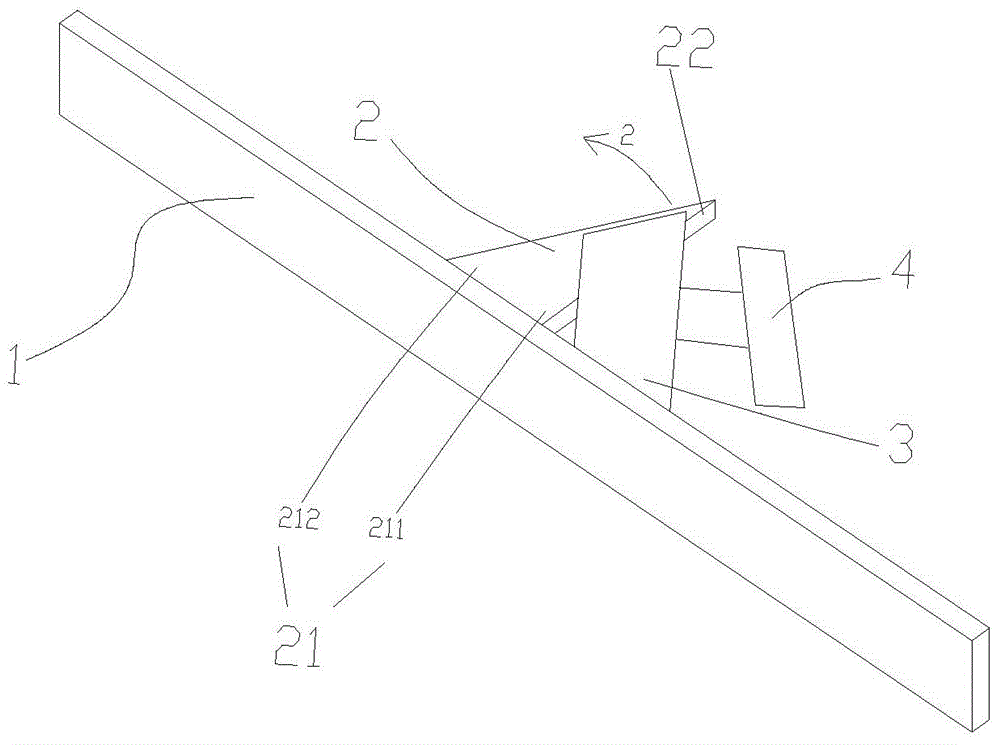

[0031] Such as figure 1 As shown, the structural schematic diagram of the first embodiment of the pressure sensing structure, the pressure sensing structure includes an operation panel 1 for the force applicator to apply pressure, and the arrow 1 indicates the position and direction of the force application; the deformation amplification component includes two mutual Independent rectangular connectors 2, the two connectors 2 are perpendicular to the back of the operation panel 1 and can be integrally formed with the operation panel 1; at the same time, the connectors 2 can also be connected with the operation panel 1 by welding, riveting and other mechanical connections; induction The unit includes a pressure sensor 3 and a control circuit 4 , the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com