Corrosion pit depth determining method by use of confocal microscope

A confocal microscope and corrosion pit technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of difficulty in measuring the depth of corrosion pits, difficult measurement, and high requirements for probe materials, so as to achieve a true and reliable data source and make up for it. The measurement accuracy is not high and the effect of broadening the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method for measuring the depth of corrosion pits by using a confocal microscope according to the present invention will be described in further detail below in conjunction with specific embodiments.

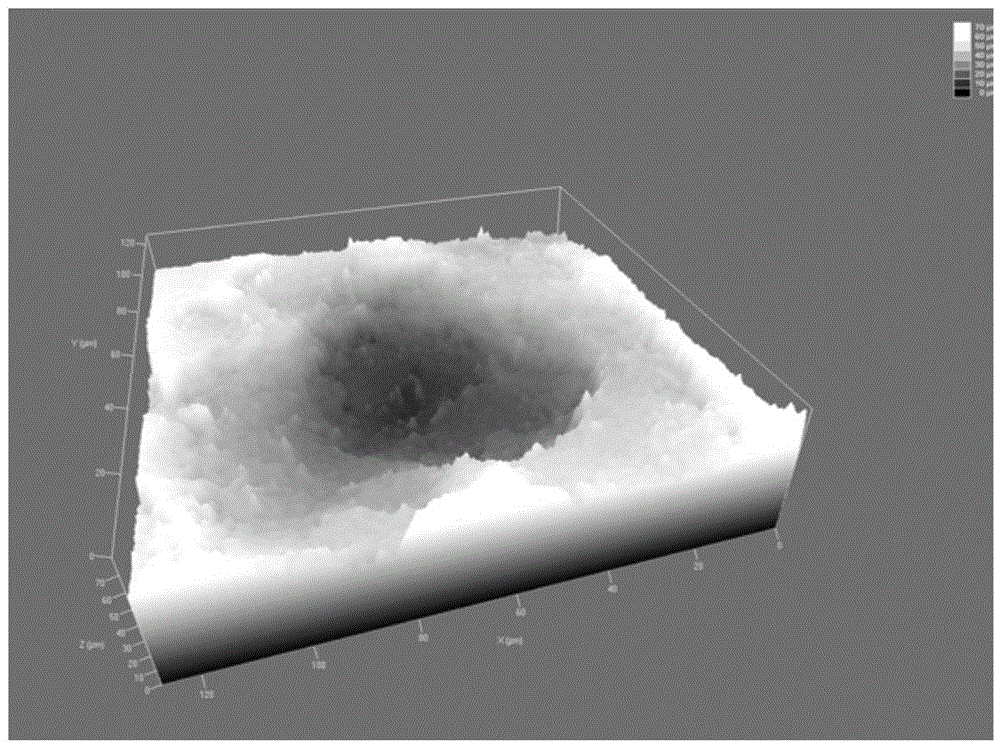

[0032] The steel grade is A690, and the standard coupon sample is made according to JB / T 7901-1999 "Metal Material Laboratory Uniform Corrosion Full Immersion Test Method". The size is 50mm×25mm×5mm. The sample simulates seawater environment for full immersion test , Select the coupon with a corrosion period of 1.5 hours as the research object, wash it with distilled water, and dry it in an oven. LSM700 confocal microscope was used to analyze and measure the depth of corrosion pits on its surface.

[0033] The method for measuring the depth of corrosion pits of the present invention will be described in further detail below in conjunction with the A690 corrosion coupon sample.

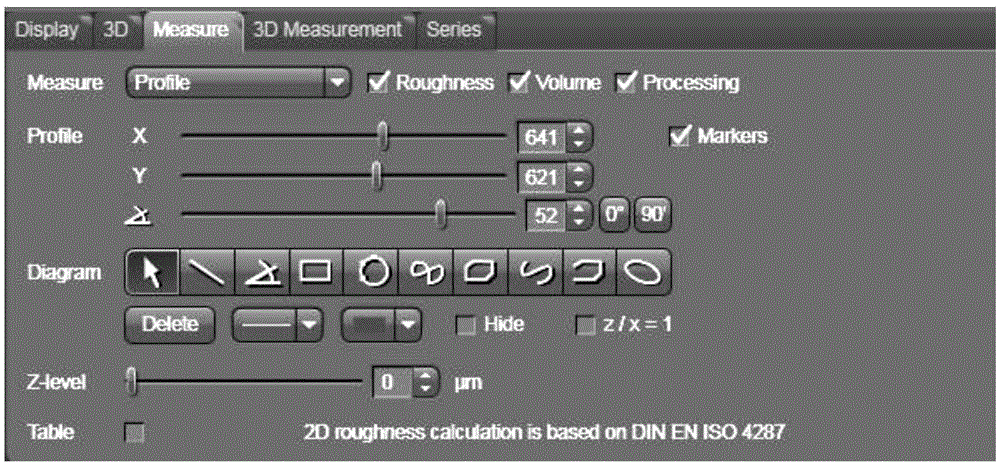

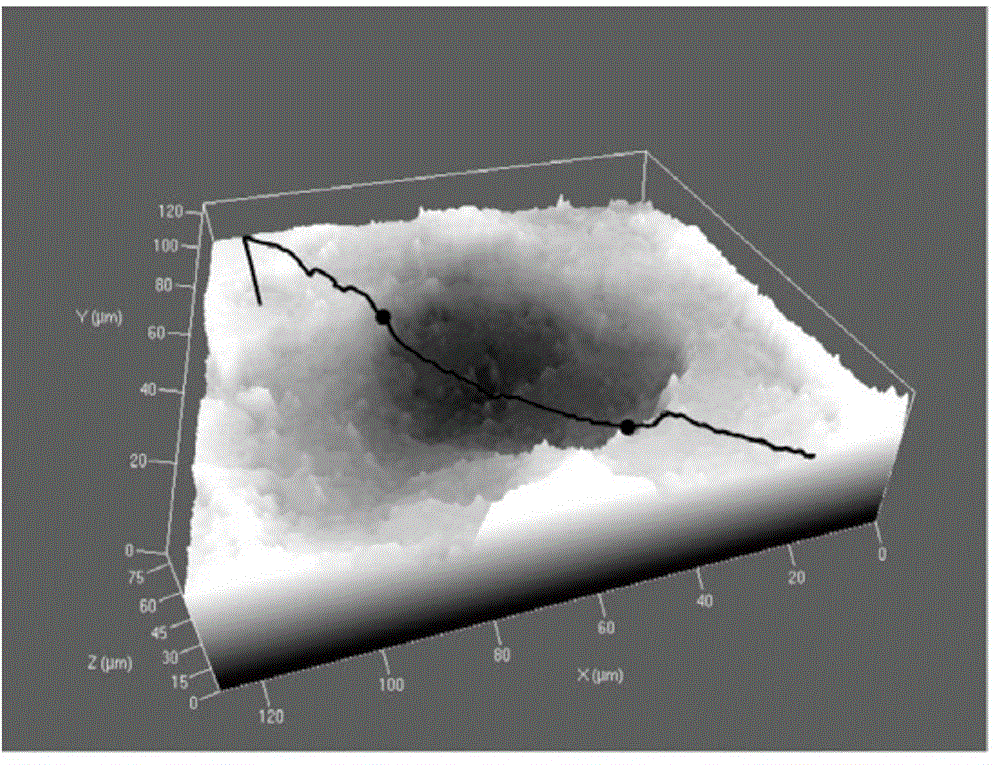

[0034] (1) Image preprocessing

[0035] To further denoise and smooth the existing 3D images, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com