New ferroalloy baking system and process based on steelmaking furnace

A ferroalloy and steel-making furnace technology, applied in the field of new ferroalloy baking system and process, can solve the problems of unreasonable process and economy, conflict of work system, waste of gas and electric energy, etc., to reduce target temperature, delay cooling rate, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

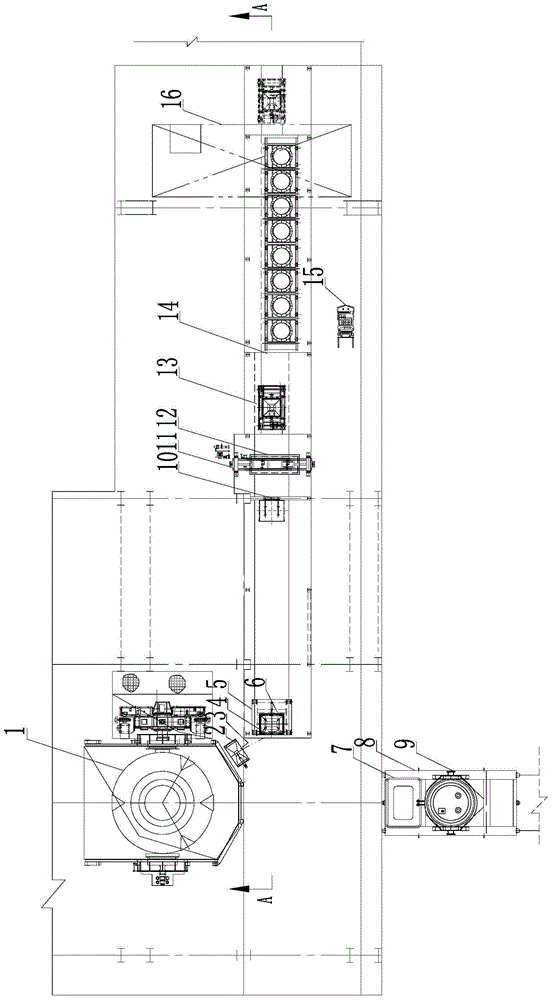

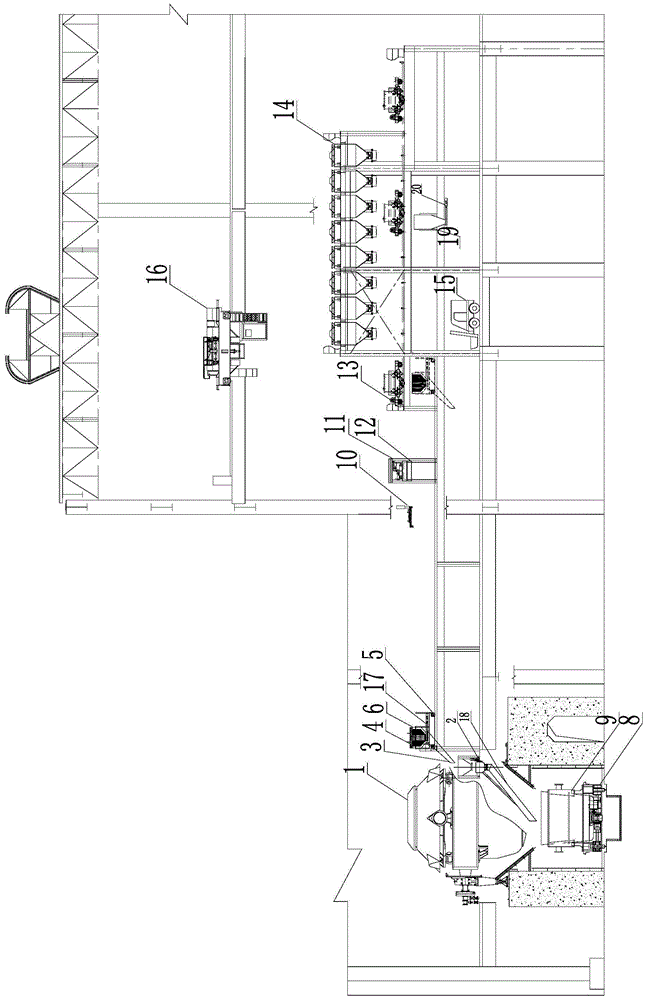

Image

Examples

Embodiment 1

[0031] This embodiment is based on the novel ferroalloy baking system of the steelmaking furnace, which includes a mobile centralized hopper, a concentrated hopper baker and a concentrated hopper insulation cover device, wherein the ferroalloy required by each steelmaking furnace is transferred from the movable concentrated hopper The receiving position is transported to the baking position, and the concentrated hopper baker bakes the ferroalloy to the target temperature, and the ferroalloy in the concentrated hopper is kept warm by the heat preservation cover device of the concentrated hopper, and the movable concentrated hopper transports The ferroalloy reaches the discharge position for discharge.

[0032] The mobile centralized bucket

[0033] Composition of mobile centralized bucket: mobile trolley, centralized bucket, electric gate valve, proximity switch, etc.

[0034] The amount of alloy required for each furnace of the steelmaking furnace is added to the centralized ...

Embodiment 2

[0050] This embodiment is based on the new ferroalloy baking process of the steelmaking furnace, which is realized by the system described in the above-mentioned embodiment 1, and the ferroalloy required by each steelmaking furnace is transported from the receiving level to the In the baking position, the ferroalloy is baked to the target temperature through the concentrating hopper baker, the ferroalloy in the hopper is kept warm through the concentrating hopper insulation cover device, and the movable concentrating hopper transports the ferroalloy to the unloading station. Material level, unloading.

[0051] 1. The present invention adopts a mobile centralized bucket, which satisfies the storage and transportation of ferroalloy for each furnace. The whole process can realize remote operation, which greatly reduces the labor intensity of on-site personnel. The storage and transportation operations are completely different from the conventional ferroalloy baking process.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com