Elbow joint arm lifting device with unpowered locked top point

A lifting device and elbow joint technology are applied in the field of lifting devices for testing the braking performance of multi-axle vehicles to achieve the effects of balanced force, reasonable structural design and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

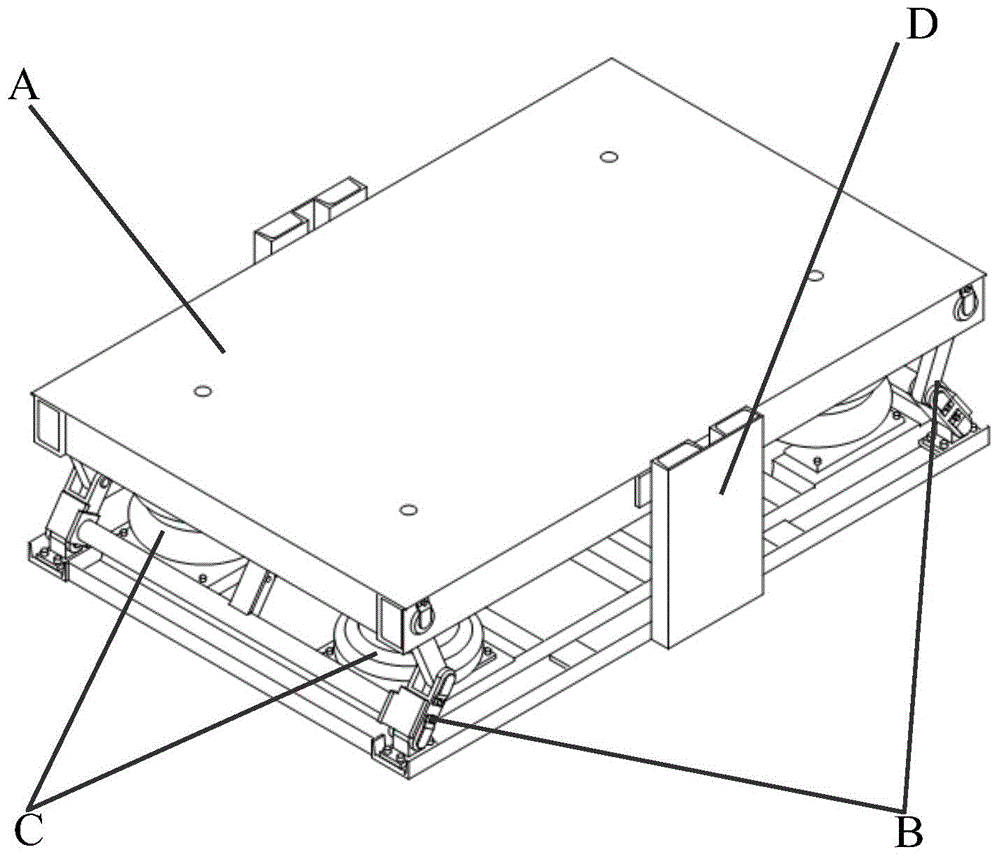

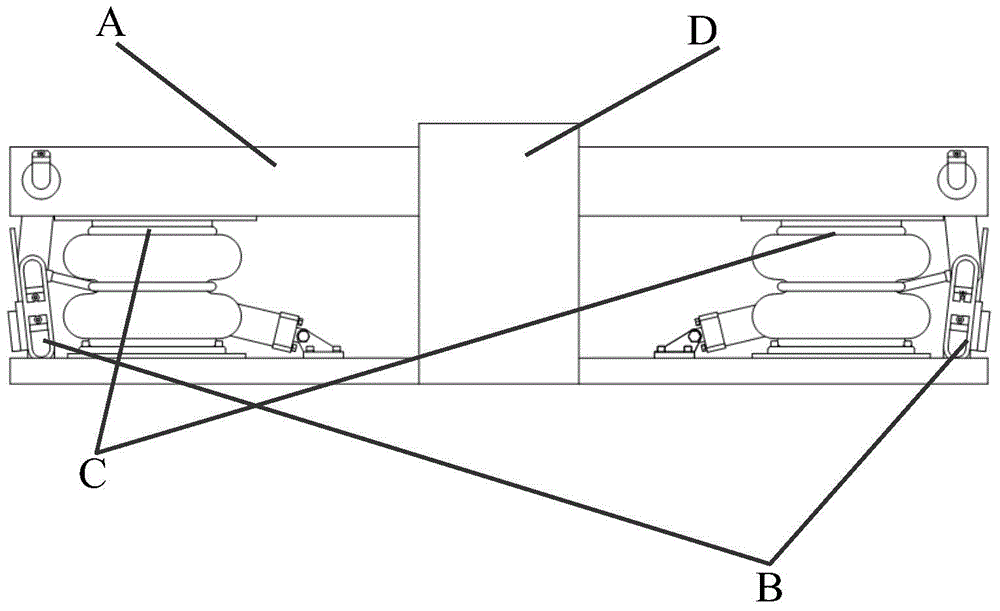

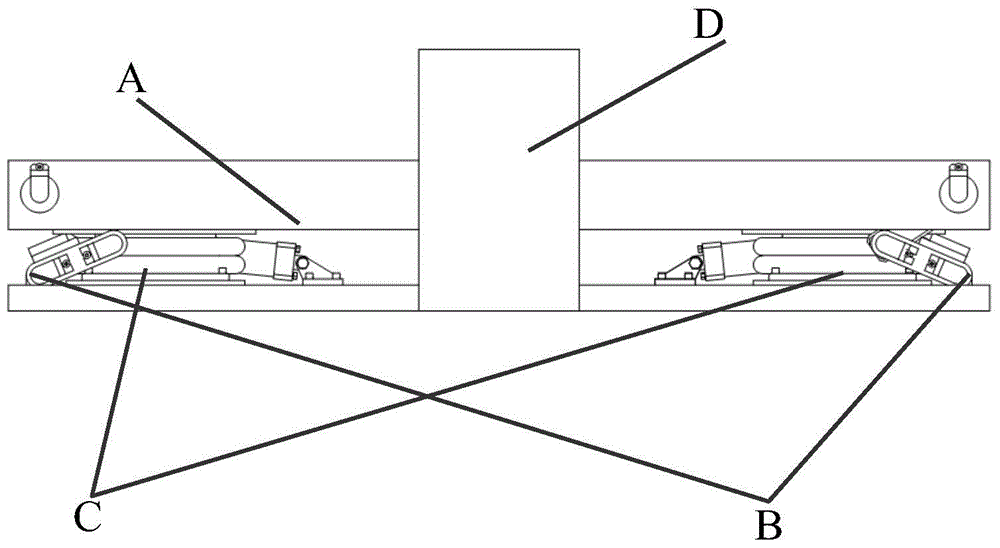

[0033] refer to figure 1 , figure 2 , image 3 , Figure 12, an elbow-joint arm lifting device with no power to lock the apex, the device includes a lifting platform mechanism A, two sets of elbow-joint arm mechanisms B, a lifting air bag mechanism C and a bottom frame mechanism D, the bottom frame The mechanism D is horizontally fixed on the foundation, the two sets of elbow-joint arm mechanisms B are fixed on the left and right ends above the bottom frame mechanism D, and the lifting airbag mechanism C is arranged at the four corners above the bottom frame mechanism D and The bottom frame mechanism D is fixedly connected by bolts; the lifting platform mechanism A is arranged above the elbow joint arm mechanism B, the lifting airbag mechanism C and the bottom frame mechanism D, and is fixedly connected with the elbow joint arm mechanism B by bolts, so The upper ends of the lifting platform mechanism A and the lifting air bag mechanism (C) are fixed by long bolts.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com