Segmental sludge high dryness pressing method

A segmented, sludge technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as damage to hydraulic components, unfavorable discharge of mud cake moisture, unfavorable hydraulic system temperature balance, etc. Moisture content, the effect of improving the dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

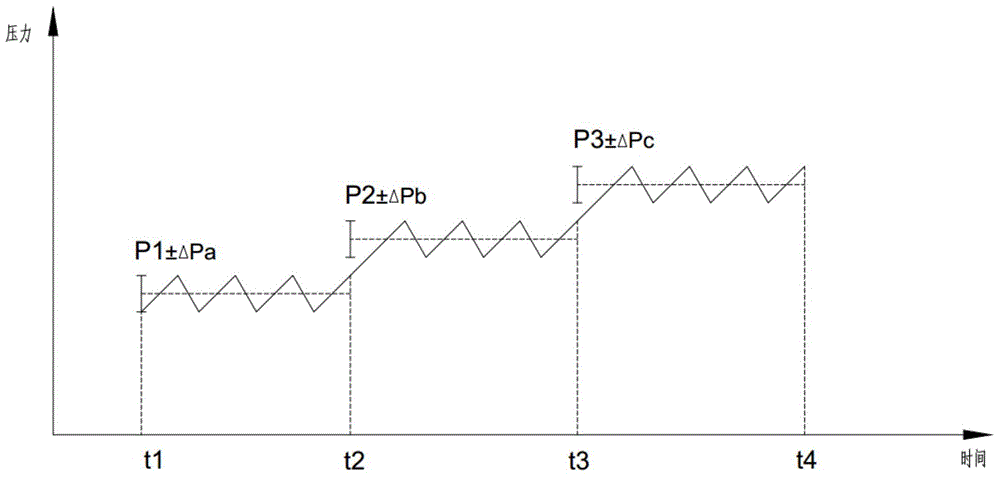

[0011] Such as figure 1 As shown, the entire pressing process is divided into multiple time periods t1-t2, t2-t3, t3-t4..., the average pressure in the same time period is a constant value, such as the average pressure in the t2-t3 time period is P2, the The actual pressure value P within the time period t2-t3 fluctuates up and down based on the average pressure P2 of this time period, and its fluctuation range is ±△P b ; The average pressure P2 of this period is greater than the average pressure P1 of the previous period t1-t2, and less than the average pressure P3 of the subsequent period t3-t4, that is, P1

[0012] Further, the peak value and valley value of the pressure in the same time period are equal, and the peak value and valley value are greater than the peak value and valley value of the previous time period, and smaller than the peak value and valley value of the subsequent time period.

[0013] Preferably, the average rate of change of the rising edge of t...

Embodiment 2

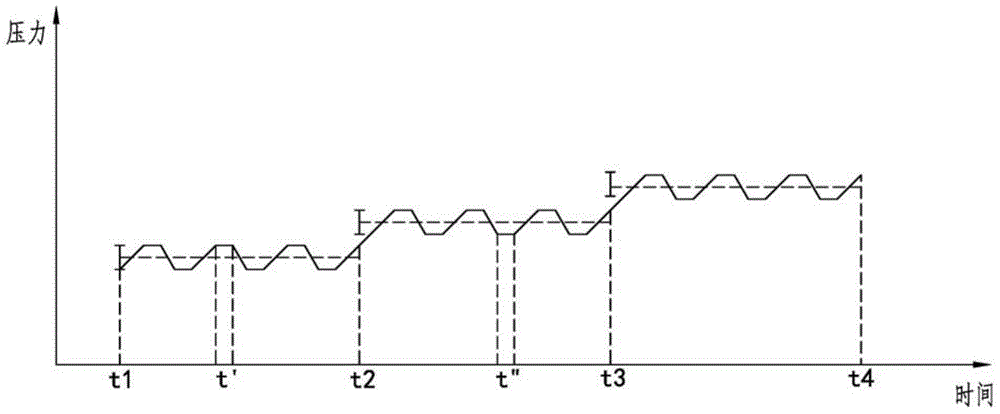

[0016] Such as figure 2 As shown, the pressure P changes intermittently, and when the pressure P is between the peak and / or valley and / or peak valley, a certain holding time t', t" is reserved to facilitate the redistribution or overflow of water Provide enough time.

[0017] In addition to the linear waves used in the above-mentioned embodiments 1 and 2, the present invention can also use nonlinear waves, such as sine waves, exponential function waves, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com