Efficient semi-automatic capsule filling device

A filling device and semi-automatic technology, applied in the directions of capsule delivery, drug delivery, pharmaceutical formulation, etc., can solve the problems of low filling efficiency and inability to realize the operation of multiple machines by one person, etc., so as to improve production efficiency and reduce positioning, installation and fixed arrangement. The time of the board, the effect of realizing the operation and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

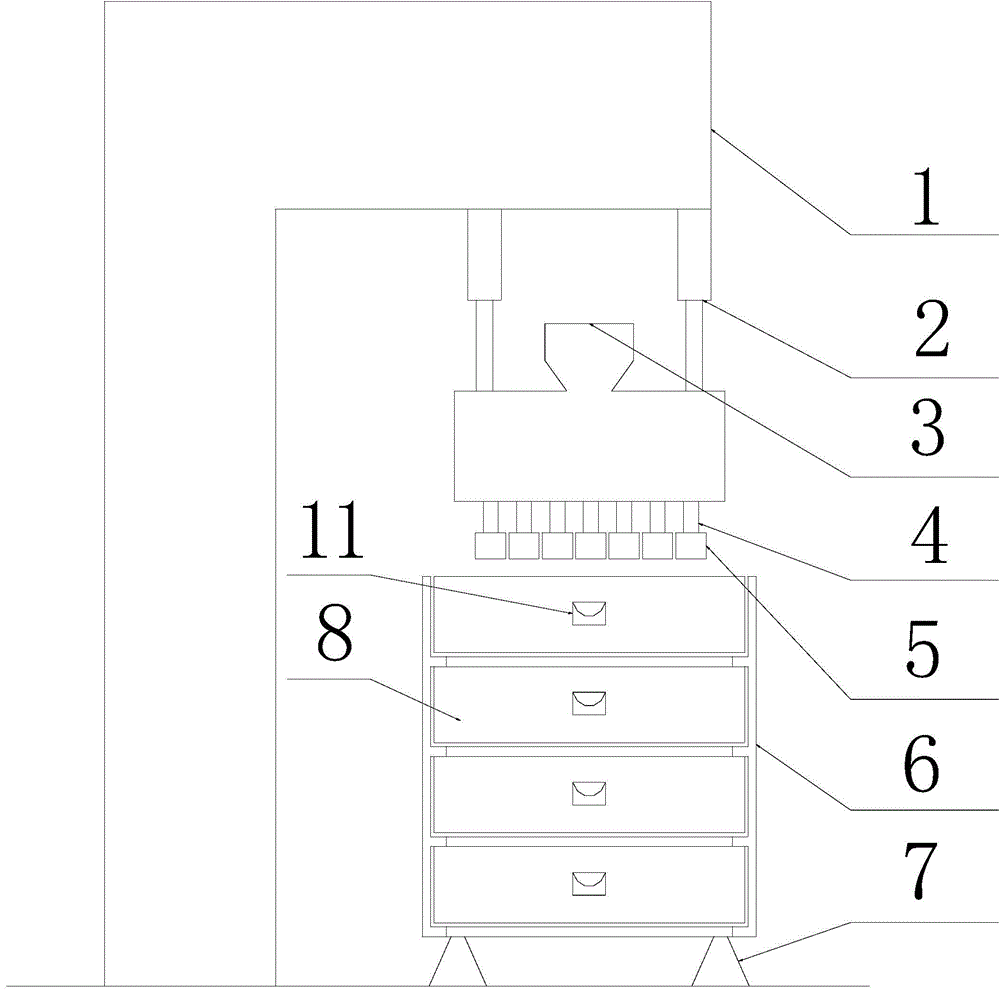

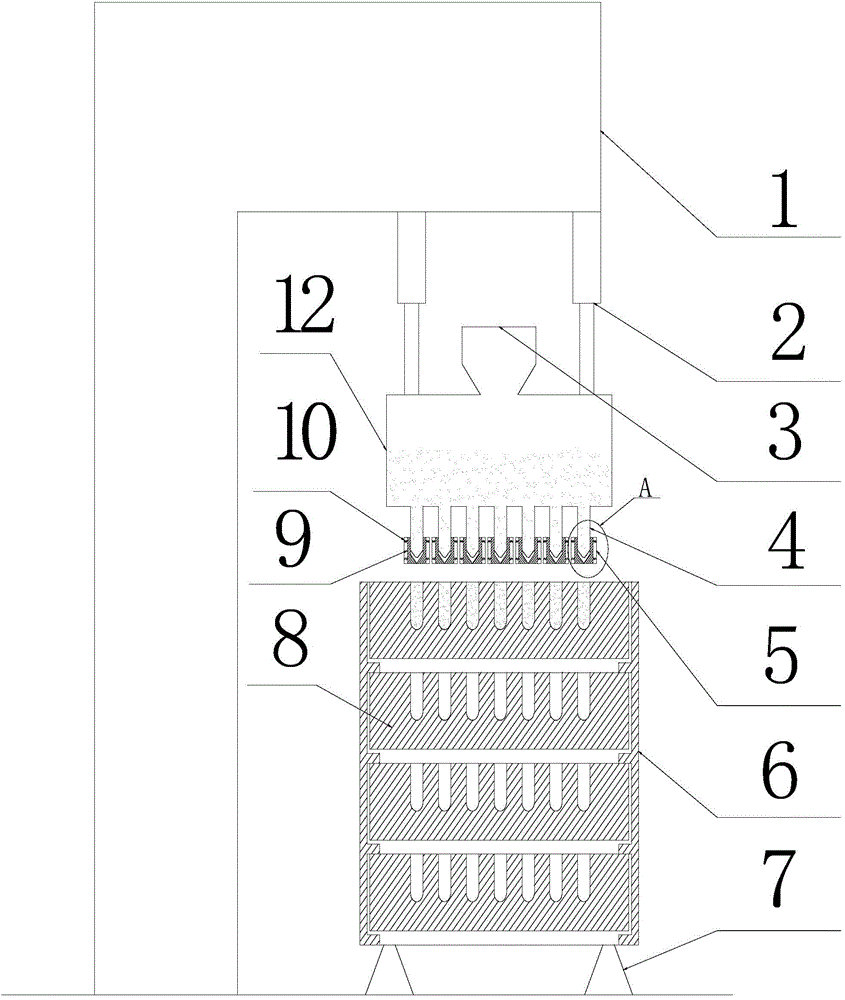

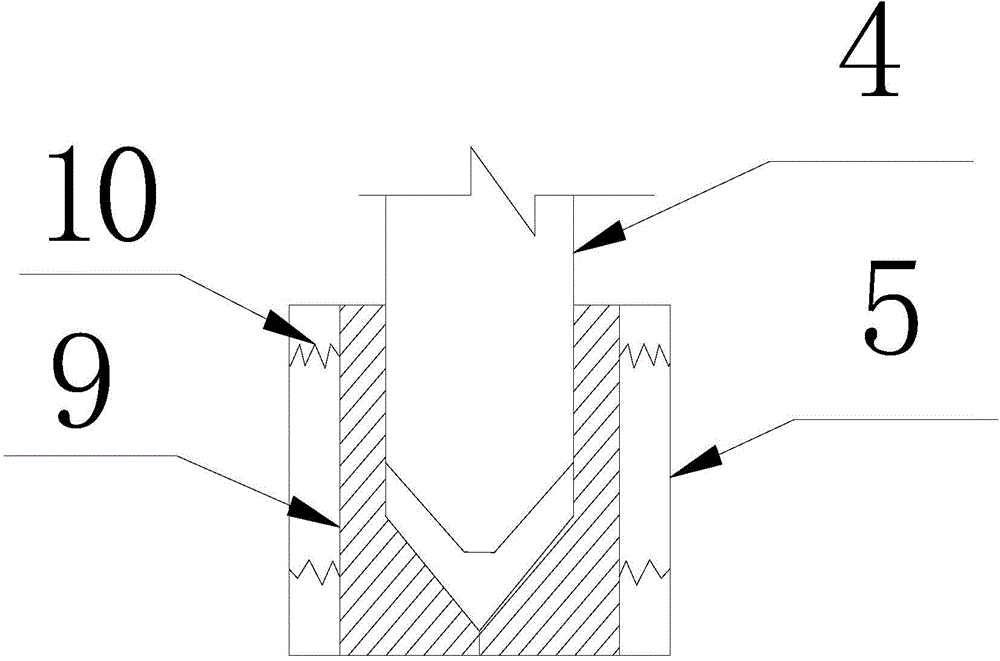

[0015] refer to figure 1 , figure 2 , image 3 , a high-efficiency semi-automatic capsule filling device of the present invention, including a hydraulic pressure generating device 1, a hydraulic telescopic rod 2, a hopper 3, a feeding port 4, a filling limit device 5, an array plate bracket 6, an array plate bracket base 7, and an array plate 8 , filling limit device inner core 9, spring 10, arrangement plate handle 11 and material storage box 12, the hydraulic pressure generation device 1 is connected with the material storage box 12 through the hydraulic telescopic rod 2, and the hopper 3 is fixed on the material storage box 12 , the discharge opening 4 is directly connected with the material storage box 12, the filling limit device 5 is sleeved on the discharge opening 4 through a spring 10, the support base 7 of the arrangement plate is fixed under the storage box 12, the Arrangement plates 8 are layered on the arrangement plate support 6, and the number of said hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com