One-step debitterizing and reducing acidity method of high pulp content juices

A technology with high pulp and fruit juice, applied in the fields of food adsorption, food preparation, food science, etc., can solve the problems of unsatisfactory juice flavor, restrict comprehensive utilization, and high fruit acid content, so as to improve the safety of juice, improve production efficiency, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

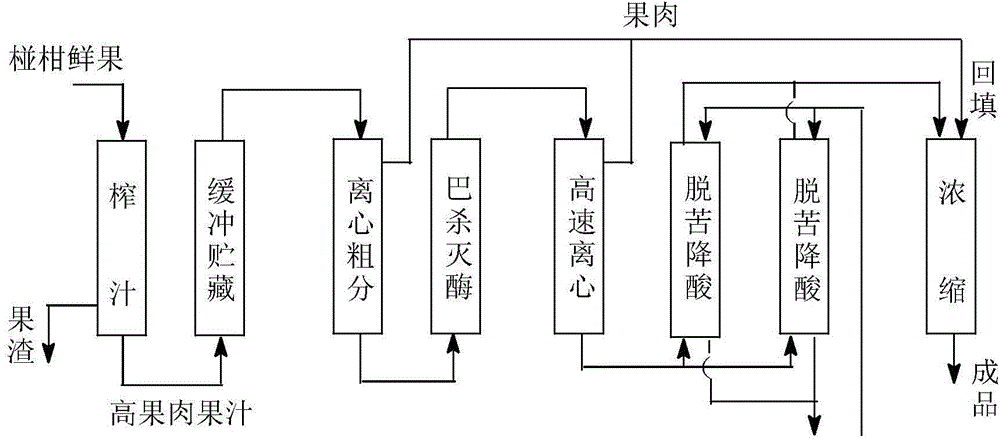

[0028] (1) Juicing: After the fresh fruit is measured, graded, and post-ripened, scrub to remove the dirt on the fruit surface, manually select and remove rotten fruit, broken fruit and impurities, send it to the classifier for classification, and then squeeze the juice to obtain the original juice and pomace Abandon it as animal feed, etc.

[0029] (2) Rough separation of fruit juice: the original juice is centrifuged at 2000rpm in a horizontal screw centrifuge to obtain juice and pulp with low pulp content (pulp content less than 3%) after rough separation, and the pulp is pumped into the recovery tank for subsequent backfilling, and the juice into the buffer tank.

[0030] (3) Juice essence separation and enzyme inactivation: The crudely separated fruit juice is then refined, and centrifuged at 6000rpm / min by a high-speed centrifuge to separate the juice and pulp, and the fruit juice with low pulp content (pulp content is less than 1%) is sterilized at 85°C for 16 seconds, ...

Embodiment 2

[0034] according to figure 1 shown in the flowchart,

[0035] (1) Juicing: After the fresh fruit is measured, graded, and post-ripened, scrub to remove the dirt on the fruit surface, manually select and remove rotten fruit, broken fruit and impurities, send it to the classifier for classification, and then squeeze the juice to obtain the original juice and pomace Abandon it as animal feed, etc.

[0036] (2) Rough separation of fruit juice: the original juice is centrifuged at 2000rpm in a horizontal screw centrifuge to obtain juice and pulp with low pulp content (pulp content less than 3%) after rough separation, and the pulp is pumped into the recovery tank for subsequent backfilling, and the juice into the buffer tank.

[0037] (3) Juice essence separation and enzyme inactivation: The crudely separated fruit juice is then refined, and centrifuged at 6000rpm / min by a high-speed centrifuge to separate the juice and pulp, and the fruit juice with low pulp content (pulp conten...

Embodiment 3

[0044] (1) Juicing: After the fresh fruit is measured, graded, and post-ripened, scrub to remove the dirt on the fruit surface, manually select and remove rotten fruit, broken fruit and impurities, send it to the classifier for classification, and then squeeze the juice to obtain the original juice and pomace Abandon it as animal feed, etc.

[0045] (2) Rough separation of fruit juice: the original juice is centrifuged at 4200rpm in a horizontal spiral centrifuge to obtain juice and pulp with low pulp content (pulp content less than 3%) after rough separation. The pulp is pumped into the recovery tank for subsequent backfilling, and the juice is packed into the buffer tank.

[0046] (3) Juice essence separation: the roughly separated juice is then refined, and centrifuged at 7500rpm by a high-speed centrifuge to separate the juice and pulp. The juice with low pulp content (pulp content is less than 1%) is sterilized at 90°C for 12 seconds, and then recycled into the next step....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com