LED driving power supply circuit board with test apparatus

A technology of LED driving and testing equipment, which is applied in the direction of electric lamp circuit layout, electric light source, lighting equipment, etc., can solve the problems of increasing testing cost and defective product rate, and achieve the effect of eliminating welding process and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

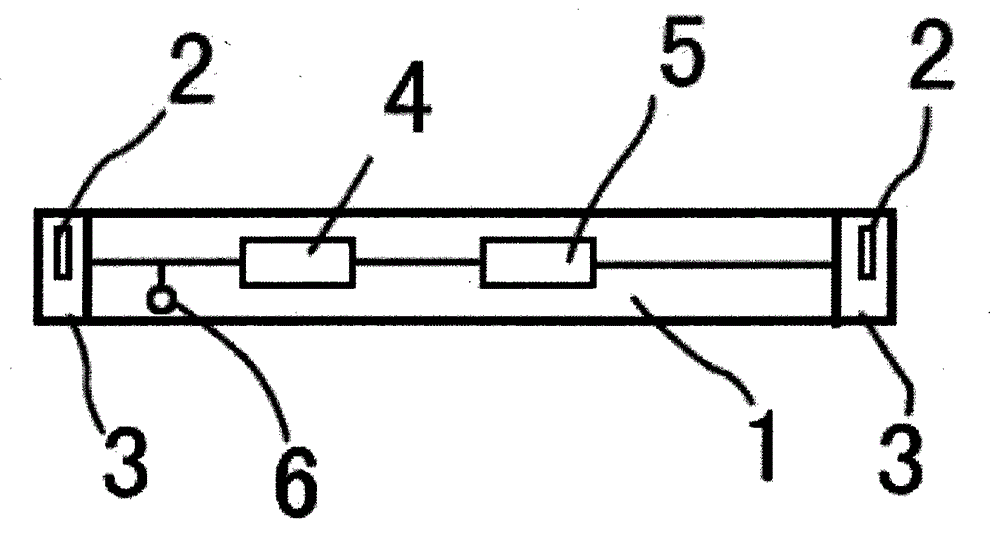

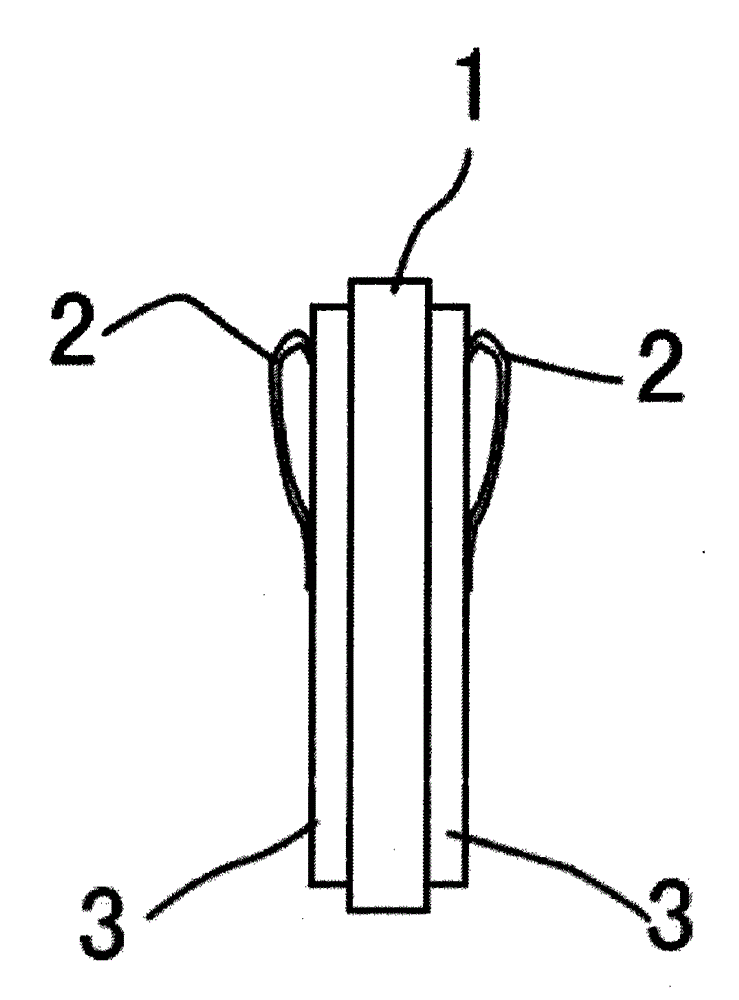

[0012] The application will be further described below in conjunction with the accompanying drawings.

[0013] Such as Figure 1-2 As shown, the LED driving power supply circuit board includes: a transformer 4, a control circuit module 5, and a circuit substrate 1. The transformer 4 and the control circuit module 5 are electrically connected to the circuit substrate 1; Electrical contact pieces 3 are provided respectively.

[0014] The electrical contact piece 3 is a rectangular solder layer with a thickness of 0.2CM, on which a metal shrapnel 2 is fixed, the metal shrapnel 2 is in the shape of a human ear, and the material is preferably a steel sheet, and each of the rectangular solder layers has at least Fix a metal dome 2. During the test, the electrical contact piece 3 is directly clamped between the shrapnel of the tester, and the test can be performed. If there is no tester during the test, just use the traditional crocodile clip to clamp on the metal shrapnel 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com