Pre-stressing force measurement apparatus and method for pre-stress steel strand

A technology of prestressed steel strands and measuring devices, which is applied in the direction of tension measurement, etc., can solve the problems of inability to load magnetic coils, aggravate sensor aging, and affect measurement accuracy, and achieve convenient and fast prestress detection, satisfying long-term monitoring, and equipment The effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

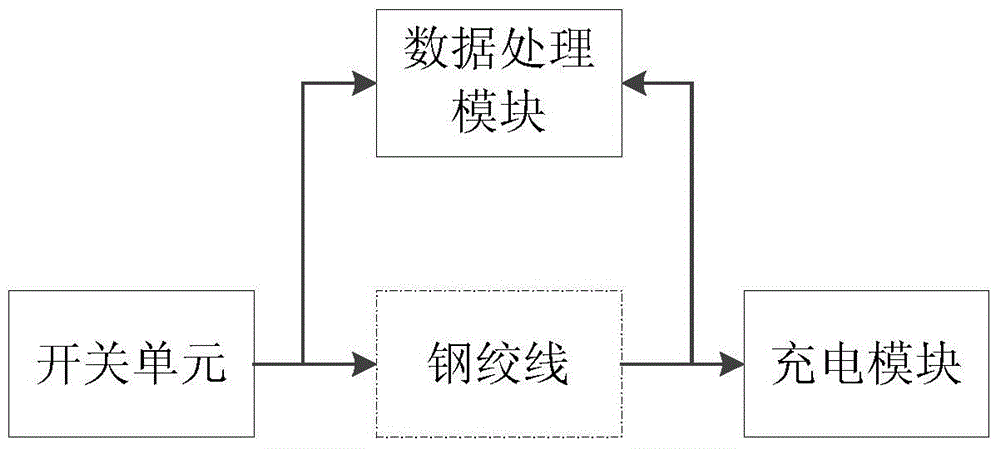

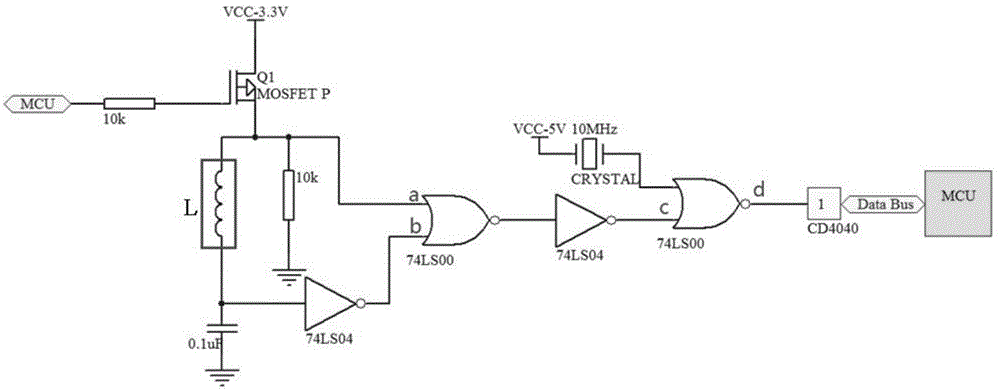

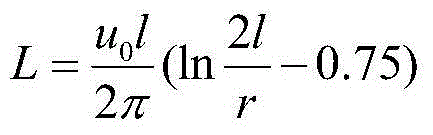

[0018] The invention provides a prestress measuring device for prestressed steel strand, which includes a switch unit, a charging module and a data processing module, the switch unit charges the charging module through the steel strand, and the data processing module collects the input of the steel strand signal and the output signal of the steel strand, the data processing module converts the input signal of the steel strand and the output signal of the steel strand into the charging time signal of the charging module, and obtains the change of the inductance of the steel strand through the variation of the charging time The amount, and then the prestress variation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com