Pressure generating device and generating method

A technology of generating device and pressure, applied in the direction of hydroelectric power generation, fluid pressure converter, machine/engine, etc., which can solve the problems of high noise, large volume and complicated manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

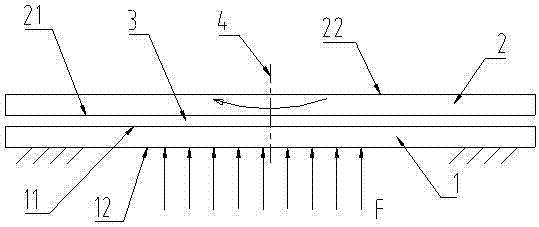

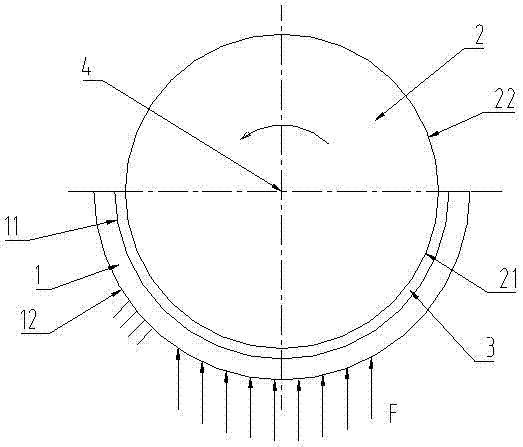

[0019] see figure 1 The shown pressure generating device includes a fixed part 1 and a moving part 2, both of which are discs, and the two discs are coaxial. The inner surface 21 of the movable part is opposite to the inner surface 11 of the fixed part up and down, and there is lubricating oil in the gap 3 between the two opposite inner surfaces, and the width of the gap 3 is less than 0.5mm. A driving mechanism (not shown) for driving the movable member to rotate relative to the fixed member around the fixed member axis 4 is connected to the movable member. During the rotation of the movable member 2, the width of the gap 3 remains substantially constant. The fixed part 1 and the moving part 2 are placed in the air, and the outer surface 22 of the moving part and the outer surface 12 of the fixed part are both in contact with the air. When the moving part rotates relative to the fixed part, since the gap 3 is very small, the force of the lubricating oil on the inner surface...

Embodiment 2

[0023] see figure 1 The pressure generating device shown includes a fixed part 1 and a moving part 2, the fixed part 1 is a half ring, the moving part 2 is a shaft, and the half ring is coaxial with the shaft (the axis coincides). The inner surface 21 of the movable part is opposite to the inner surface 11 of the fixed part up and down, and there is lubricating oil in the gap 3 between the two opposite inner surfaces, and the width of the gap 3 is less than 0.5mm. A driving mechanism (not shown) for driving the movable member to rotate relative to the fixed member around the fixed member axis 4 is connected to the movable member. During the rotation of the movable member 2, the width of the gap 3 remains substantially constant. The fixed part 1 and the moving part 2 are placed in water, and the outer surface 22 of the moving part and the outer surface 12 of the fixing part are both in contact with the water. When the moving part rotates relative to the fixed part, since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com