Automatic double-releasing device for pulsator washing machine

A pulsator washing machine, automatic feeding technology, applied to washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of increased user workload, user's hand pollution, not simple and beautiful, etc., to avoid residual deterioration, easy Empty, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

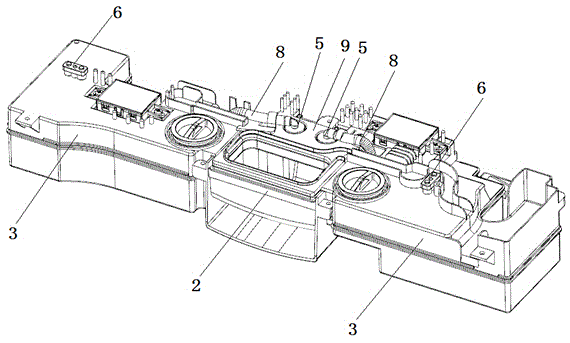

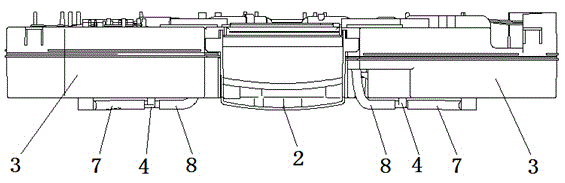

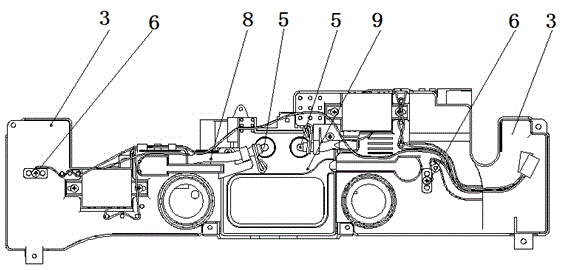

[0022] Such as Figure 1 to Figure 4 As shown, a dual automatic feeding device for a pulsator washing machine includes a computer board 1, a water inlet box 2, a storage box 3, a gear pump 4, a one-way valve 5, a liquid level sensor 6, a first hose 7 and a second flexible hose There are two pipes 8, among which, the storage tank 3, the gear pump 4, the one-way valve 5, the liquid level sensor 6, the first hose 7 and the second hose 8 are provided with two. Two storage boxes 3 are respectively arranged on the left and right sides of the water inlet box 2, one is used for storing liquid detergent, and the other is used for storing liquid softener, and is connected with the water inlet box 2 and the setting by means of plugging and screw fastening. Fixing the shower assembly 9 above the water inlet box 2 can ensure a tight and stable structural f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com