Continuous overturning mechanism and method for smart card

A smart card and flip card technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

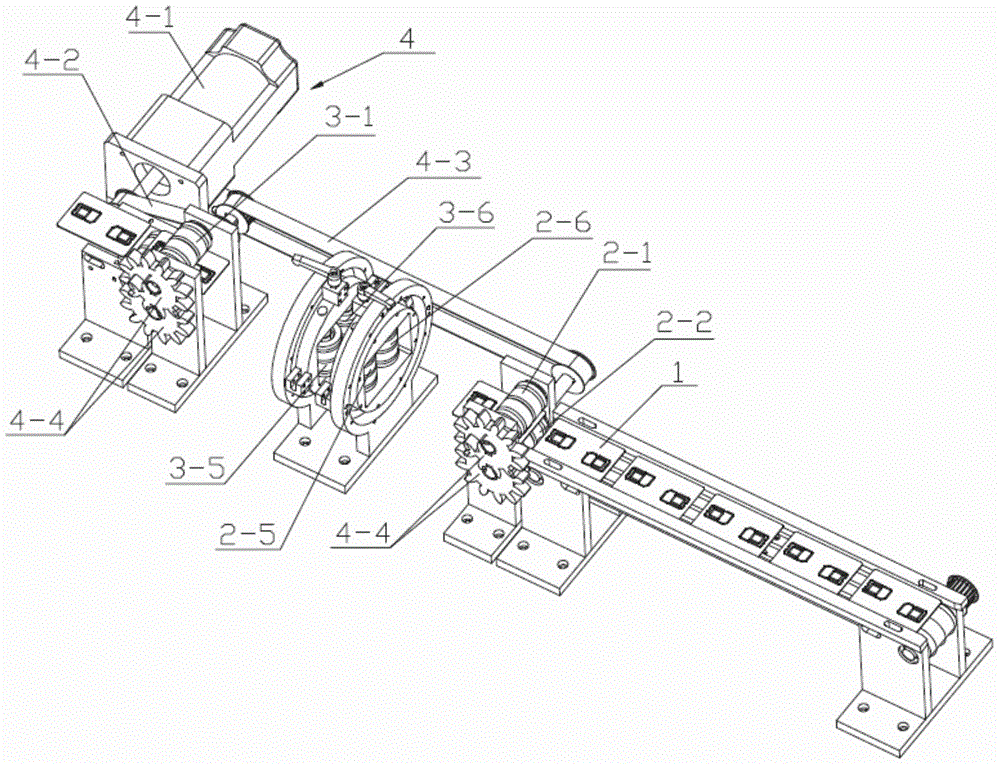

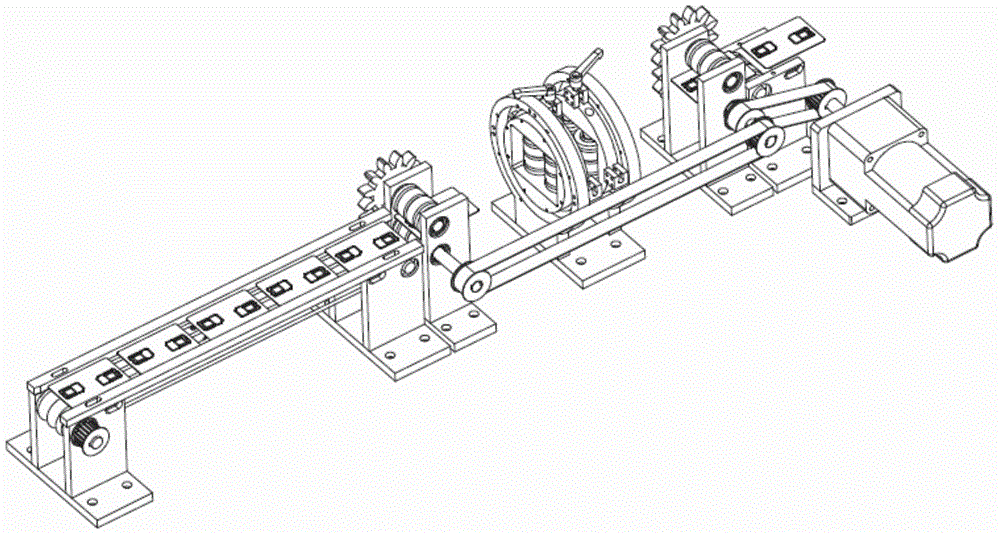

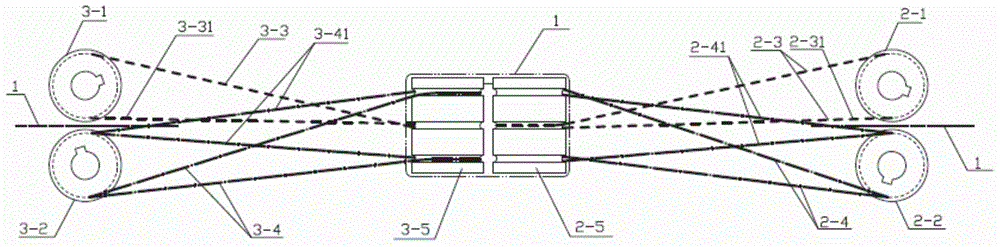

[0042] see Figure 1 to Figure 5 The continuous card turning mechanism of the smart card of the present invention comprises a power mechanism 4, a first card turning unit 2 and a second card turning unit 3, along the conveying direction of the card 1, the first turning unit 2 and the second turning unit The card units 3 are arranged in sequence. in:

[0043] The first card turning unit 2 includes a set of horizontal rollers, a set of vertical rollers and a conveyor belt. Along the conveying direction of the card 1, the set of horizontal rollers and the set of vertical rollers are arranged in sequence; the set of horizontal rollers includes an upper horizontal roller 2 -1 and the lower horizontal roller 2-2, the gap between the upper horizontal roller 2-1 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com