Horizontal adjusting mechanism of coating machine

A technology of level adjustment and coating machine, which is applied in the device, coating, laminating device and other directions of coating liquid on the surface, can solve the problems of reducing production efficiency, uneven bonding, inconvenience, etc., and achieves good production and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

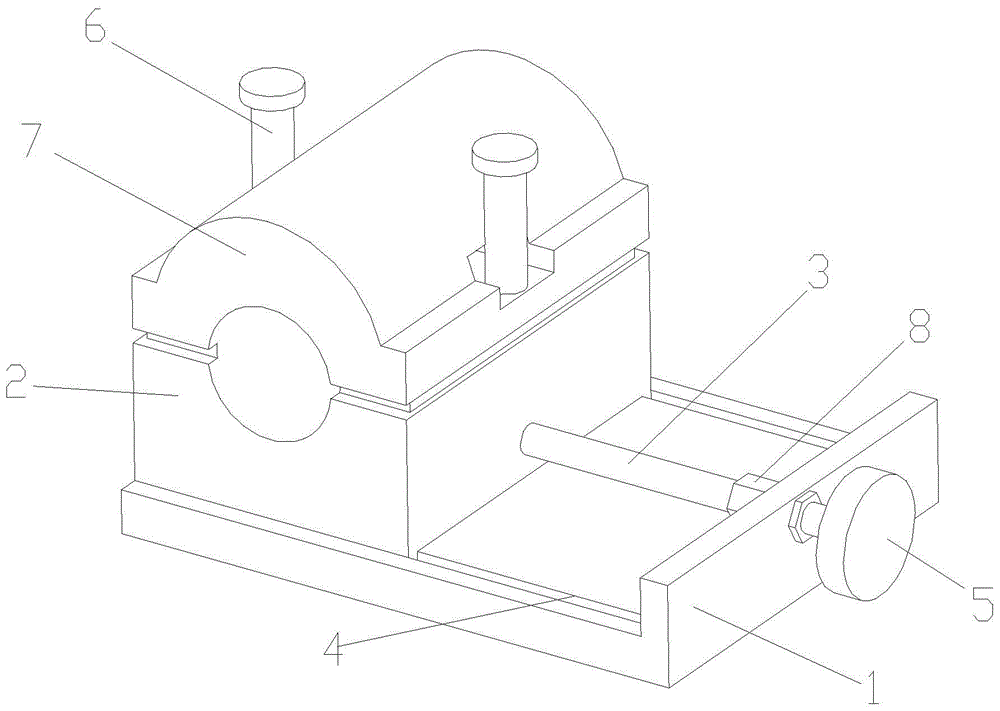

[0012] attached figure 1 It is a horizontal adjustment mechanism for a coating machine according to the present invention, which includes a base 1, a sliding seat 2 and an adjustment screw 3; the sliding seat 2 is arranged on the base 1 and can move along the chute 4 of the base 1; One end of the adjusting screw 3 is connected to the sliding seat 2, the other end passes through the base 1 and an adjusting wheel 5 is installed; the sliding seat 2 is equipped with a compression cover 7 through a fixing bolt 6; A fixed nut 8 is provided at the contact with the sliding seat 2, and the fixed nut 8 is used to adjust the fixation of the screw rod 3 and the sliding seat 2 to prevent slipping.

[0013] When in use, install a horizontal adjustment mechanism for a coating machine of the present invention on the position of the corresponding feed roller of the coating machine, and by setting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com