Device for quickly combining washers with screws and method for applying device

A technology of combining washers and washers, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high work efficiency, and high error rate, and achieve simple and safe operation, high combination efficiency, and low error rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

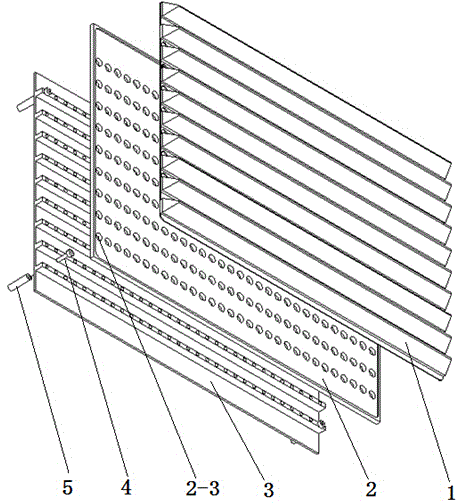

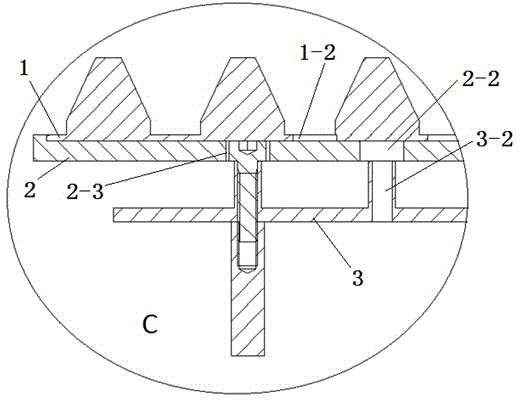

[0018] Such as Figure 1 to Figure 10 As shown, a quick combined washer screw device includes a washer positioning plate 1, a washer stop plate 2, a combined screw tray 3, a hexagon socket head cap screw 4, and a stud 5.

[0019] The gasket positioning plate 1 is rectangular, and several projections 1-1 are arranged at intervals on the surface of the gasket positioning plate 1, and several large-diameter holes I1-2 are arranged at intervals on the plate surface between each pair of projections 1-1 .

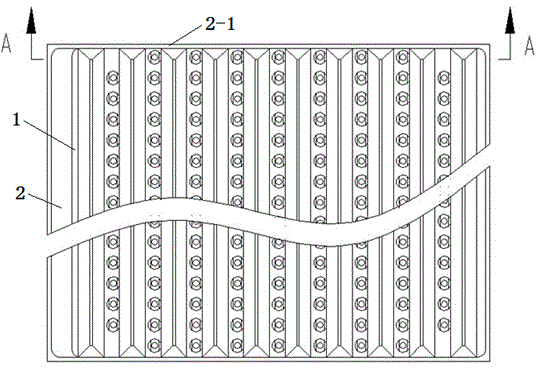

[0020] The washer stay plate 2 is rectangular, and the periphery of the washer stay plate 2 plate surface is a circle of raised edge 2-1, and the gasket stay plate 2 plate surface in the raised edge 2-1 is provided with several large-diameter holes II2- 2. Several large-diameter holes II2-2 are symmetrical and have the same diameter as several large-diameter holes I1-2. The length of the washer stay plate 2 is less than the length of a circle of raised edge 2-1. The four corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com