Lifting and compacting mechanism of horizontal parting slip flask shoot-squeeze molding machine

A technology of horizontal parting and molding machines, which is applied to molding machines, manufacturing tools, casting molding equipment, etc. It can solve the problems of easy tilting of the lifting box piston cover and insufficient rigidity of the lifting and compacting mechanism, etc., to increase the guide length , enhance the rigidity and strength, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

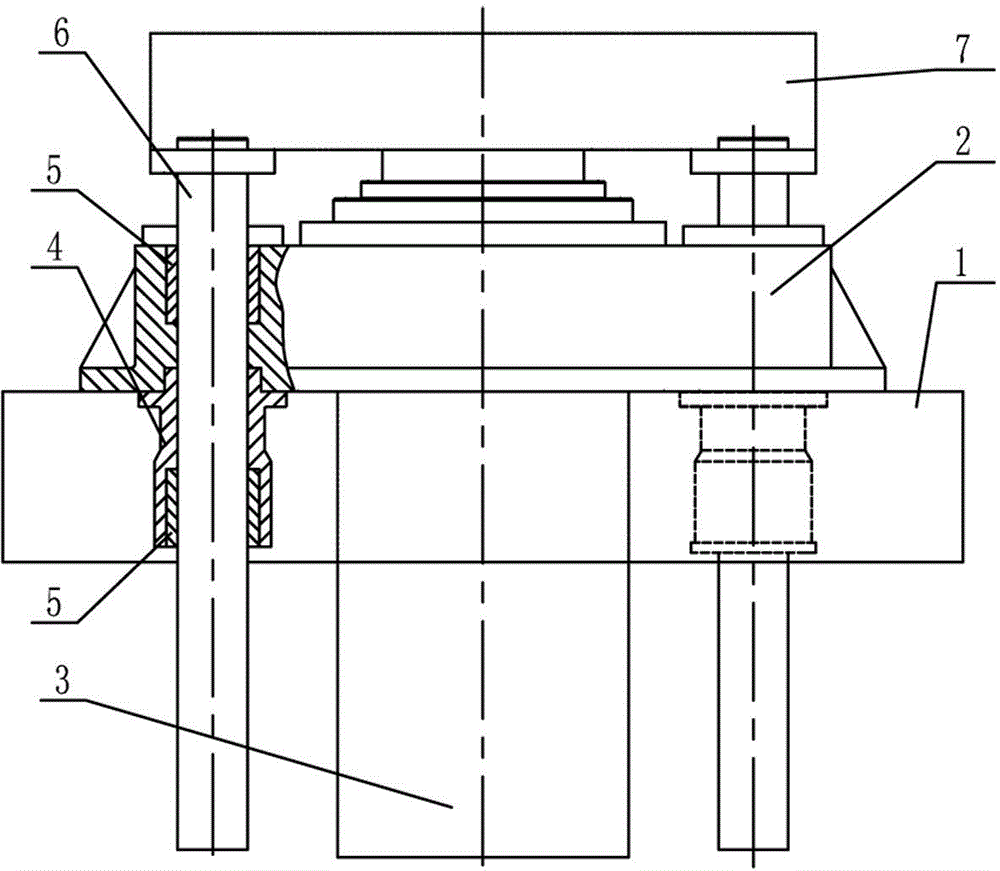

[0021] Such as Figure 3-4 As shown, the lifting and compacting mechanism of a horizontal parting box-removing injection molding machine according to an embodiment of the present invention includes a bottom beam 1, a main cylinder 3, a main cylinder base 2, a box lifting piston cover 7 and a lifting The guide rod 6, the main cylinder base 2 is fixed on the bottom beam 1, the main cylinder 3 is installed on the main cylinder base 2, and the box lift piston cover 7 is fixed on the end surface of the piston rod of the main cylinder 3. The lift guide rod 6 includes four, Each lifting guide rod 6 is provided with a guide sleeve 4 and two copper sleeves 5 correspondingly. The four guide sleeves 4 are correspondingly distributed at the four top corners of the main cylinder base 2. At the same time, the four lifting guide rods 6 are installed separately In the corresponding guide sleeve 4, the top end of the lifting guide rod 6 is inserted into the lower end of the box lifting piston c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com