Steel structure integral hoisting method based on BIM

An overall hoisting and steel structure technology, applied in the direction of building structure, building material processing, special data processing applications, etc., to achieve the effects of improving accuracy and safety, reducing costs, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, it should be understood that following specific embodiment is only for illustrating the present invention and is not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the invention Modifications in various equivalent forms fall within the scope defined by the appended claims of the present application.

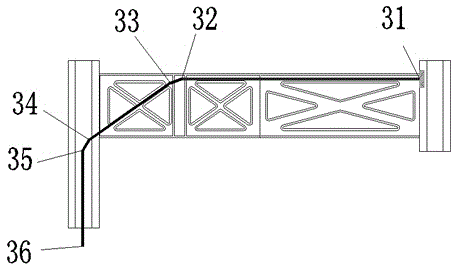

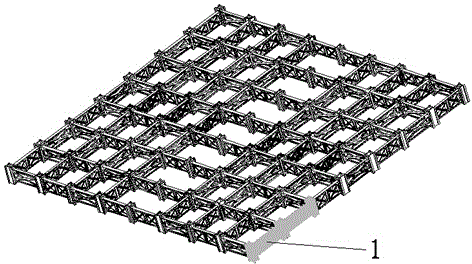

[0020] Use BIM software to calculate the component deflection, determine the camber of a single truss, check the component deflection during the construction process and compare it with the pre-camber, and compare the deflection after construction and loading with the design control deflection requirements; use the MIDAS finite element analysis plug-in By setting lifting points at the intersection of the truss upper chord and diagonal rod and each truss, design and calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com