Sample preparation device, sample preparation shear device and sample preparation shear test method suitable for direct shear test of jointed rock mass

A technology of jointed rock mass and shearing device, which is applied in the direction of applying stable shear force to test the strength of materials and the preparation of test samples, and can solve problems such as damage to rock mass structure, impact on test results, and changes in joint geometry , to avoid damage, ensure test results, and improve overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

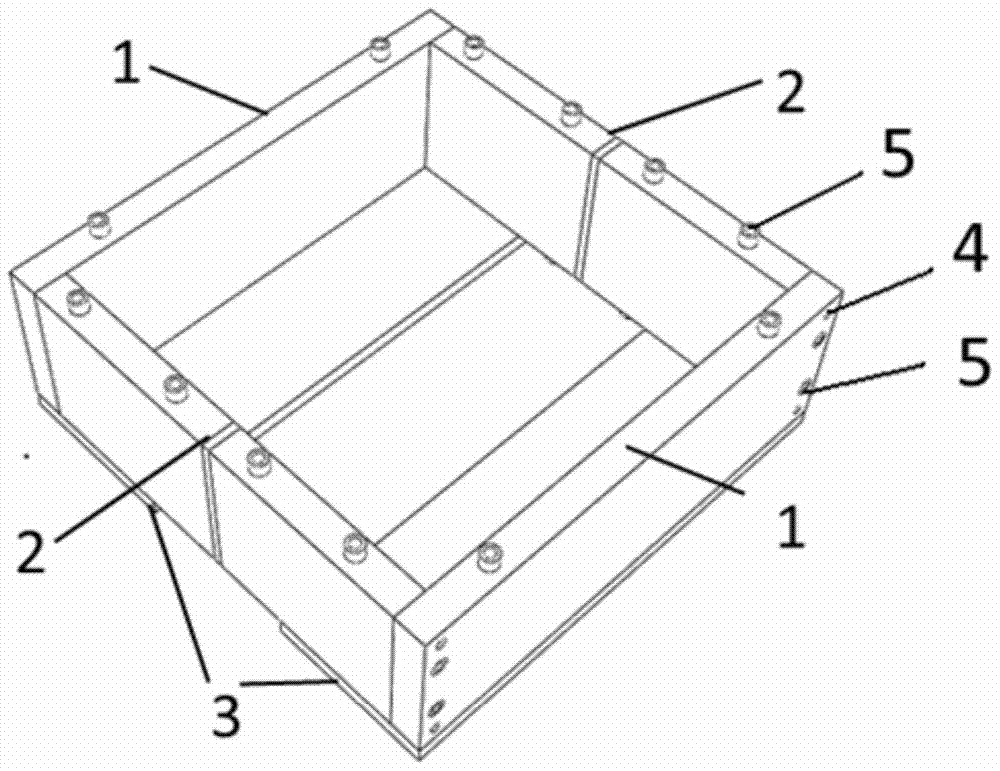

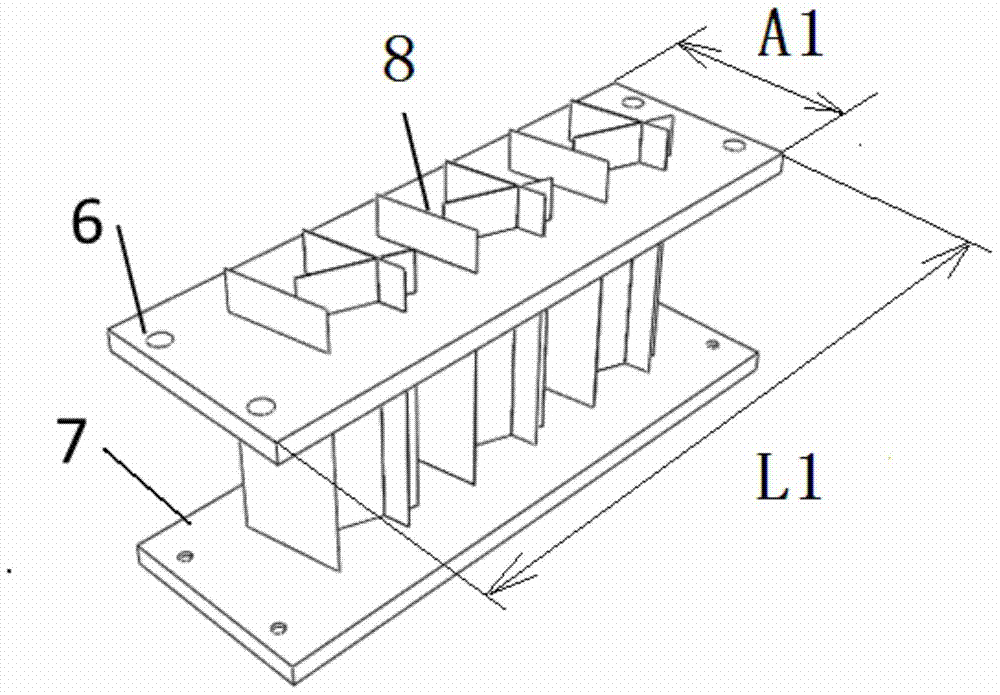

[0052] The sample preparation device suitable for direct shear test of jointed rock mass provided by the invention comprises a sample preparation component and a joint forming component.

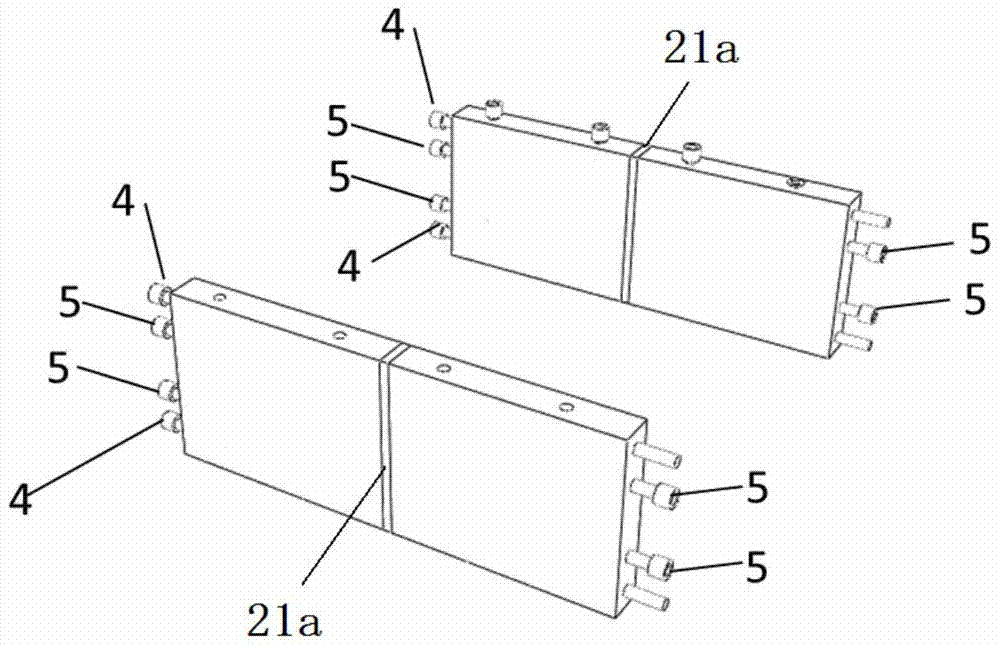

[0053] Such as figure 1 As shown, the sample preparation assembly includes a cylinder with a quadrangular cross-section, which has four side plates fixedly connected by a fixed short screw 5, and the four side plates can all be a whole plate, or can be as follows figure 1 As shown, the pair of side plates arranged opposite to each other is that each side plate is composed of a whole plate to form a bottom plate 1; the other pair of side plates oppositely arranged is a baffle plate 2, each including two , the gap 21 between the two plates is parallel to the axis of the cylinder and the gaps of the two baffles are aligned with each other, and the gap 21 is sealed by a seal; the gap between the two plates in the baffle 2 The sealing member of the gap 21 can be a rubber pad fixed between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com