High-precision rubber ball monitoring device

A monitoring device and high-precision technology, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problems of high labor intensity, mechanical wear, and low precision, so as to reduce labor intensity and occupy an area The effect of less space and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

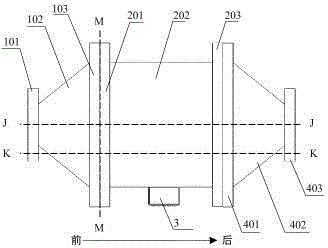

[0021] Combine below Figure 1~6 The specific structure and working engineering of the present invention are described in detail, and the description in the drawings is exemplary, and is only used to explain the present invention, but not to be construed as a limitation of the present invention.

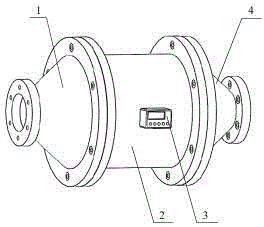

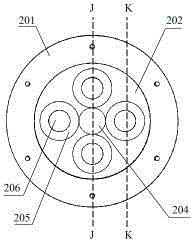

[0022] The rubber ball monitoring device includes the following parts: expansion chamber 1, diversion chamber 2, control display 3, diameter reduction chamber 4, multiple photoelectric sensors 301, multiple flow sensors 302 and connection control display 3, photoelectric sensor 301 and flow sensor 302 electrical connection wire (not marked in the figure).

[0023] The expansion chamber 1 is used to connect the circulating water pipeline 8 and the distribution chamber 2, including the expansion chamber inlet flange 101, the expansion chamber cover 102 and the expansion chamber outlet flange 103; wherein the expansion chamber inlet flange 101 is connected to the circulation The water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com