C25 green high-performance concrete prepared from all recycled coarse aggregate

A technology of high-performance concrete and recycled coarse aggregate, which is applied in climate sustainability, sustainable waste treatment, solid waste management, etc. Achieve the effect of green environmental protection, convenient production and easy construction in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

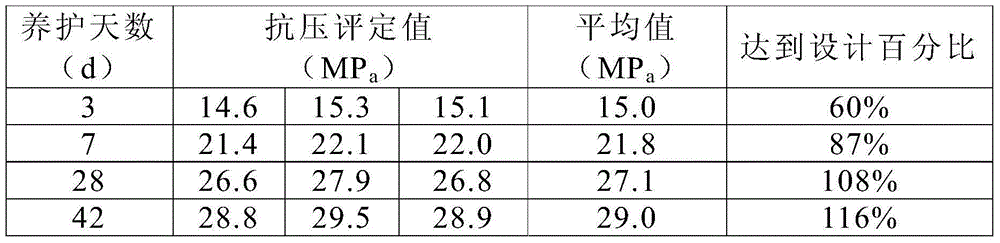

Embodiment 1

[0014] In a preferred embodiment of the present invention, after the waste concrete is crushed, the obtained particle size is 5-31.5mm in continuous gradation, the mud content is 0.4%, the needle flake particle content is 8%, the crushing index is 11.3%, and the replacement rate is 100% recycled coarse aggregate, the indicators of recycled coarse aggregate should meet the "General Concrete Stone Quality Standards and Inspection Methods", and the recycled coarse aggregate should meet the requirements of "Specification for Recycled Coarse Aggregate for Concrete". Concrete was prepared according to the ratio shown in Table 1.

[0015] Table 1 Concrete mix ratio

[0016] Cement P.O42.5

310kg

Class II fly ash

60kg

S95 grade mineral powder

80kg

SP404 superplasticizer

9kg

water

85kg

Sand in zone II with a fineness modulus of 2.8

738kg

recycled coarse aggregate

1018kg

[0017] The method is: put 73...

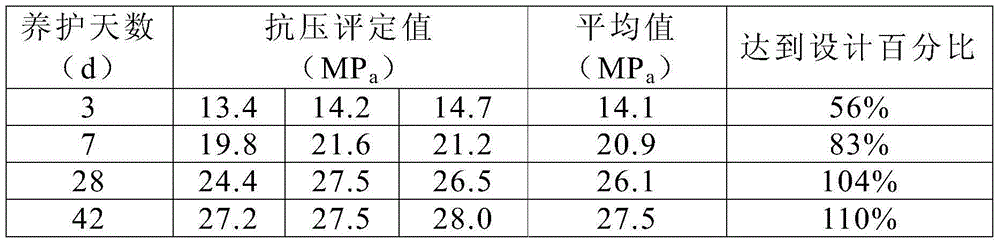

Embodiment 2

[0022] In the second embodiment of the present invention, the recycled coarse aggregate with a replacement rate of 100% is used, and the indicators of the recycled coarse aggregate should comply with the "General Concrete Stone Quality Standards and Inspection Methods", and the recycled coarse aggregate should be It meets the requirements of "Specification for Recycled Coarse Aggregate for Concrete". Concrete was prepared according to the ratio shown in Table 3.

[0023] Table 3 concrete mix ratio

[0024] Cement P.O42.5

237kg

Class II fly ash

69kg

S95 grade mineral powder

45kg

SP404 superplasticizer

6.6kg

water

191kg

Sand in zone II with a fineness modulus of 2.8

771kg

recycled coarse aggregate

970kg

[0025] The method is: put 771kg of natural sand, 970kg of regenerated coarse aggregate and 57.3kg of water into a stationary mixer, and stir for 15s; then add 237kg of cement, 45kg of minera...

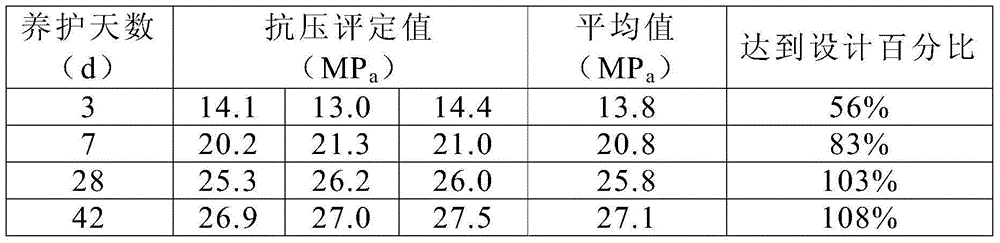

Embodiment 3

[0030] In the third embodiment of the present invention, the recycled coarse aggregate with a substitution rate of 100% is used, and the indicators of the recycled coarse aggregate should comply with the "General Concrete Stone Quality Standards and Inspection Methods", and the recycled coarse aggregate should be It meets the requirements of "Specification for Recycled Coarse Aggregate for Concrete". Concrete was prepared according to the proportion shown in Table 5.

[0031] Table 5 concrete mix ratio

[0032] Cement P.O42.5

230kg

Class II fly ash

61kg

S95 grade mineral powder

51kg

SP404 superplasticizer

6.27kg

water

191kg

Sand in zone II with a fineness modulus of 2.8

776kg

recycled coarse aggregate

1005kg

[0033] The method is as follows: put 776kg of natural sand, 1005kg of recycled coarse aggregate and 57.3kg of water into a stationary mixer, and stir for 15 seconds; then add 230kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com