Yarn guiding seat for textile

A yarn guide seat and yarn guide needle technology is applied in the directions of thin material processing, filament transportation, transportation and packaging, etc., which can solve the problems of the yarn guide needle not being able to guide the yarn, the loss of users, and the disorder of the yarn. Achieve the effect of smooth yarn guide, convenient assembly and disassembly, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

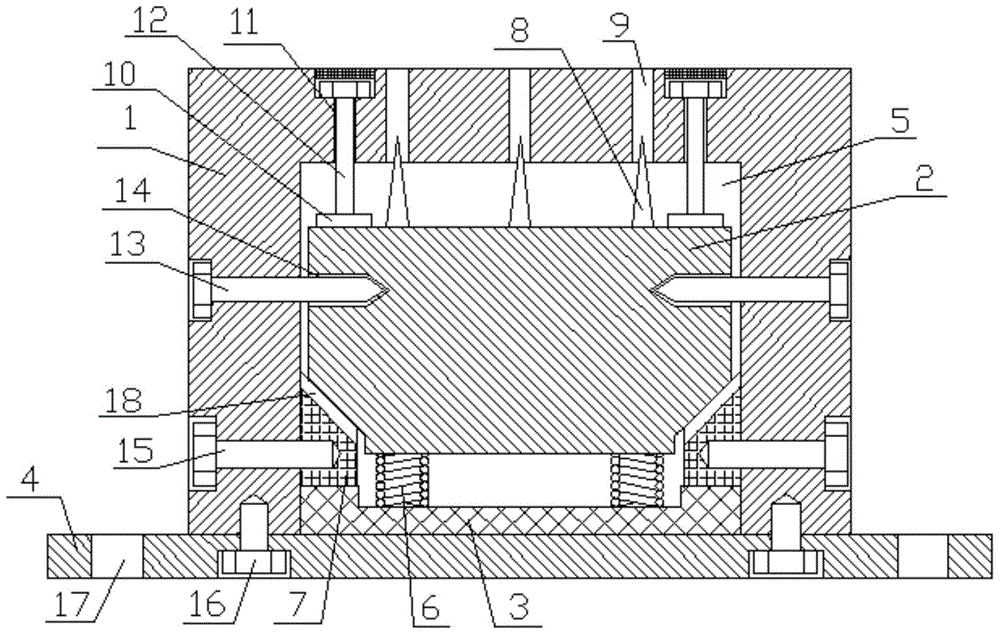

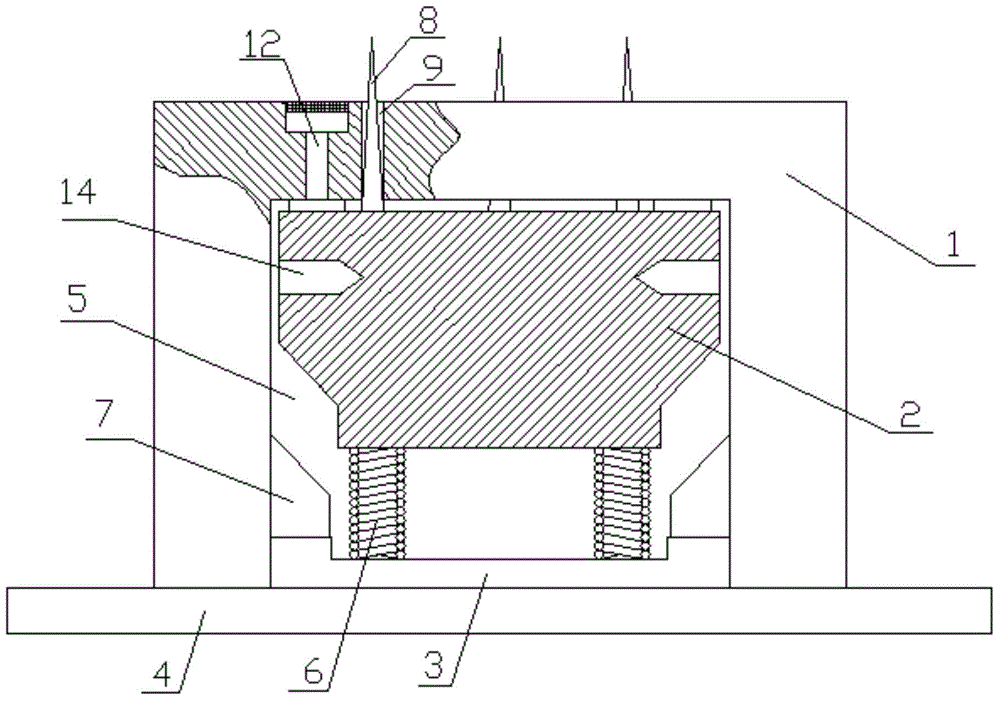

[0013] refer to figure 1 and figure 2 The shown yarn guide seat for textile includes a fixed seat 1, a moving block 2, a fixed part 3 and a mounting plate 4, the fixed seat 1 is arranged on the mounting plate 4, and a Groove 5, the moving block 1 is set in the groove 5, the fixed part 3 is set in the bottom of the groove 5, and is against the mounting plate 4, and the fixed part 3 is provided with a reset Spring mechanism 6, the upper part of the return spring mechanism 6 is offset against the moving block 2, and two limiting blocks 7 are symmetrically arranged on both sides of the fixed part 3, and the upper part of the limiting block 7 and the lower part of the moving block 2 In cooperation, a guide needle 8 is provided at the top of the moving block 2, and a through hole 9 for the guide needle 8 to pass through is provided on the fixed seat 1 at the top of the groove 5. Two fixed blocks 10 are symmetrically arranged on both sides of the upper part of the moving block 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com