A track-type sealed packing box

A packaging box and rail-type technology, applied in the field of rail-type sealed packaging boxes, can solve the problems that the airtight performance index of the sealed packaging box cannot be met, the storage and transportation of goods are inconvenient, and the volume of the metal packaging box is large. Function, novel structure design, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

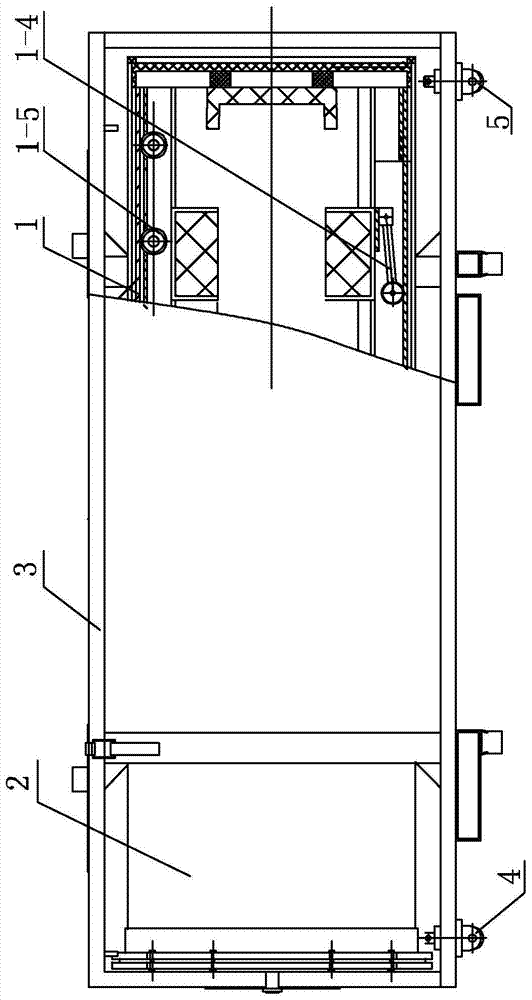

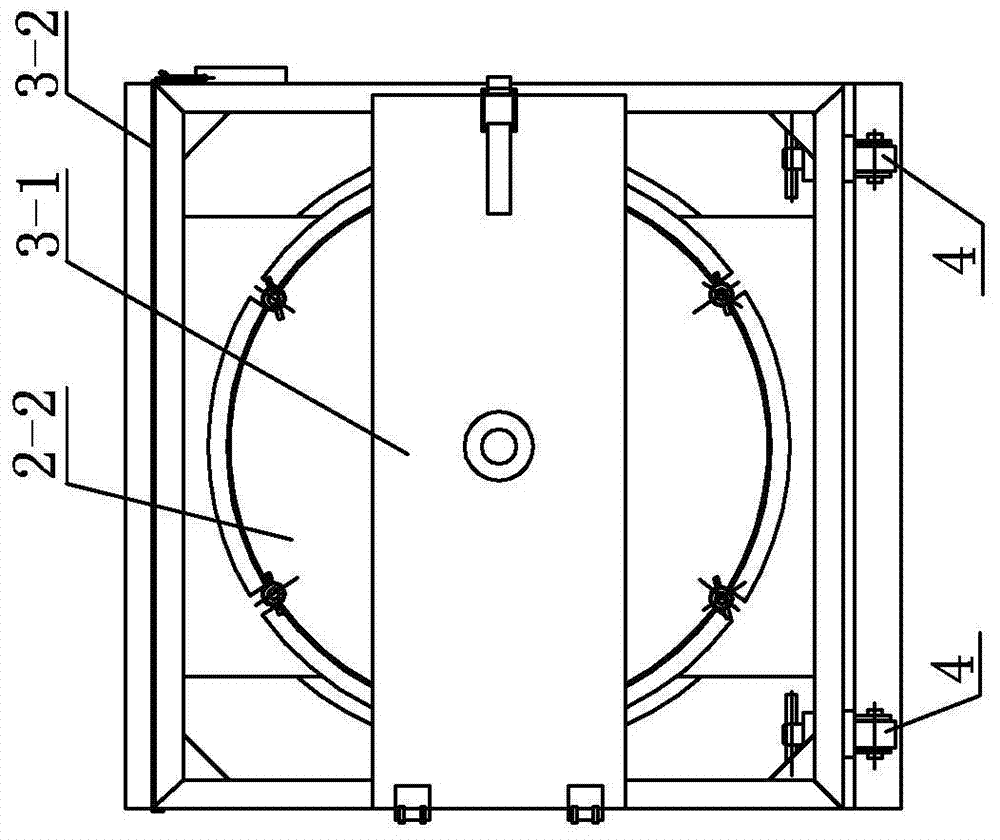

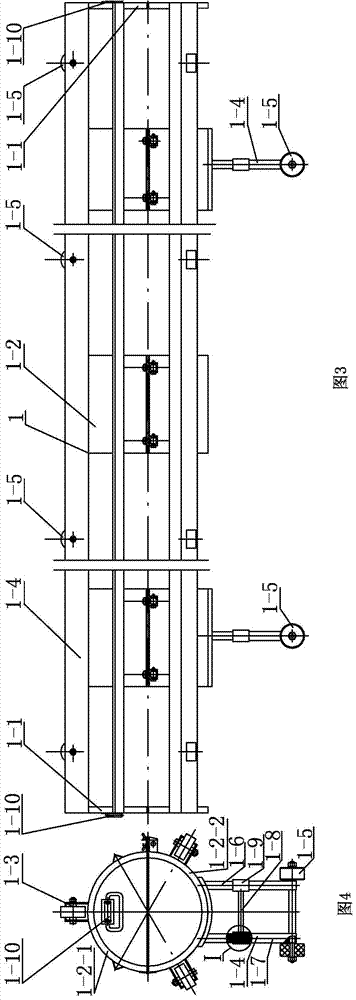

[0013] Specific implementation mode one: combine Figure 1-Figure 6 To illustrate this embodiment, a rail-type sealed packing box of this embodiment includes a trolley 1, a sealing body 2 and a frame body 3; the frame body 3 is a rectangular frame body, and one end of the frame body 3 has a door cover 3-1;

[0014] The sealing body 2 is installed in the frame body 3; the sealing body 2 includes a cylinder body 2-1, a sealing cover 2-2, a plurality of tracks 2-3 and a plurality of track bands 2-4; the cylinder body 2- The axial direction of 1 is parallel to the length direction of the frame body 3, the cylinder body 2-1 is a cylinder body with one end closed and the other end open, and a plurality of track straps 2-4 arranged side by side along the length direction of the cylinder body 2-1, A plurality of track straps 2-4 are attached to the inner wall of the cylinder 2-1, and the track straps 2-4 are connected to the cylinder 2-1, and the inside of the cylinder 2-1 is along th...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 6 This embodiment will be described. The cylindrical body 2-1 in this embodiment is formed by winding glass fiber cloth. In this way, both the cylinder body and the sealing cover have excellent electrical insulation, corrosion resistance, moisture resistance, rust resistance, acid and alkali resistance, and high strength, which effectively guarantees the long-term storage of the product. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 6 This embodiment will be described. The cylindrical body 2-1 in this embodiment is formed by winding carbon fiber cloth. In this way, both the cylinder body and the sealing cover have excellent electrical insulation, corrosion resistance, moisture resistance, rust resistance, acid and alkali resistance, and high strength, which effectively guarantees the long-term storage of the product and maintains better product performance. . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com